Medical stone porous ceramic and preparation method thereof

A porous ceramic and medical stone technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of inability to precipitate beneficial elements and minerals for the human body, limited durability and exchange function, and inability to play a role. Excellent adsorption and exchange functions, reducing energy consumption, preventing loss and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of medical stone porous ceramics, the weight percentage of its raw material is: 40% of alkaline feldspar; 39.5% of plagioclase; 20% of quartz; 0.5% of carboxymethyl cellulose. The production process steps of its products include: (1) mixing the raw materials evenly according to the proportion, and feeding; (2) grinding according to the mass ratio of material:ball:water of 1:1.5:0.8, and the grinding time is 15 hours; (3) ) Sieve the ground mixture. During the sieving process, use a 250-mesh sieve with a sieve allowance <0.5%, then design according to the application requirements, extrude, and repair the surface to remove the plugging mud; (4) Sinter the obtained green body in an oxidation flame at 1000° C. for 6 hours, and cool with the furnace to obtain the Maifan porous ceramic.

Embodiment 2

[0021] A kind of medical stone porous ceramics, the weight percent of its raw material is: alkaline feldspar 50%; plagioclase feldspar 40%; quartz 9%; sodium humate 1%. The production process steps of its products include: (1) mixing the raw materials evenly according to the proportion, and feeding; (2) grinding according to the mass ratio of material:ball:water of 1:1.5:0.8, and the grinding time is 20 hours; (3) ) Sieve the ground mixture. During the sieving process, use a 250-mesh sieve with a sieve allowance <0.5%, then design according to the application requirements, extrude, and repair the surface to remove the plugging mud; (4) Sinter the obtained green body in an oxidation flame at 1050° C. for 8 hours, and cool with the furnace to obtain the Maifan porous ceramic.

Embodiment 3

[0023] A kind of medical stone porous ceramics, the weight percent of its raw material is: alkaline feldspar 45%; plagioclase feldspar 40%; quartz 14.2%; carboxymethyl cellulose 0.8%. The production process steps of its products include: (1) mixing the raw materials evenly according to the proportion, and feeding; (2) grinding according to the mass ratio of material:ball:water of 1:1.5:0.8, and the grinding time is 18 hours; (3) ) Sieve the ground mixture. During the sieving process, use a 250-mesh sieve with a sieve allowance <0.5%, then design according to the application requirements, extrude, and repair the surface to remove the plugging mud; (4) Sinter the obtained green body in an oxidation flame at 1025° C. for 7 hours, and cool with the furnace to obtain the Maifan porous ceramic.

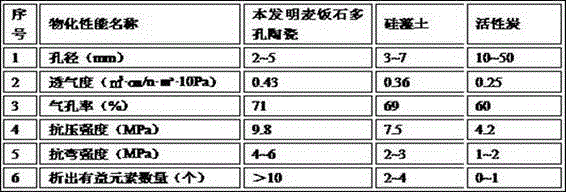

[0024] The medical stone porous ceramic prepared by the invention can better maintain its original porosity, has excellent adsorption and exchange functions, and can prevent the loss and vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com