High-performance acrylic amino baking varnish and preparation method thereof

An acrylic amino, high-performance technology, applied in the direction of coating, etc., can solve problems such as inability to reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

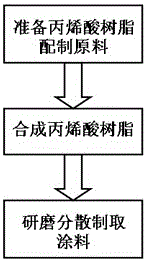

[0015] figure 1 It is a process step chart of the preparation method of high-performance acrylic amino baking varnish in the embodiment of the present invention; the raw material components contained in the acrylic amino baking varnish include: acrylic resin, 582-2 amino resin, medium chrome yellow, titanium dioxide, iron oxide red, phthalocyanine Blue, carbon black, Deqian 5500 defoamer, BYK-163 dispersant, BYK-300 silicone leveling agent, dibutyl phthalate plasticizer, the preparation method includes the following steps: a) preparing Raw materials for acrylic resin preparation, b) Synthetic acrylic resin, c) Grinding and dispersing to prepare paint.

[0016] The high-performance acrylic amino baking varnish mentioned in the present invention uses self-made acrylic resin as the main base material, and is prepared by adding various pigments and fillers, amino resin cross-linking agents with reasonable proportions and other suitable coating additives. Acrylic amino baking varn...

Embodiment

[0018] The specific preparation method is as follows:

[0019] a) Prepare raw materials for acrylic resin preparation, the specific preparation process is: first weigh 22% of xylene, 8% of ethylene glycol butyl ether, 14% of butanol, 28% of styrene, 17.5% of Butyl acrylate, 5.5% of β-hydroxypropyl acrylate, 1% of dibenzoyl peroxide, 1.5% of acrylic acid, 2.5% of methyl methacrylate; then styrene, butyl acrylate, acrylic acid- Mix β-hydroxypropyl ester, acrylic acid, methyl methacrylate and 2 / 3 dibenzoyl peroxide initiator evenly to make component A; then mix 1 / 5 xylene, 1 / 5 ethylene di Alcohol butyl ether and 1 / 3 of dibenzoyl peroxide initiator are mixed evenly to make component B.

[0020] b) Synthesize acrylic resin, the specific preparation process is: first put 4 / 5 xylene, 4 / 5 ethylene glycol butyl ether and all butanol into a heating container equipped with a stirring device and mix evenly, and heat up to 80°C ; Then add component A prepared in step a) dropwise, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com