Road marking patch and preparation method thereof

A technology for road markings and road markings, which is applied in coatings, anti-corrosion coatings, textiles and papermaking, etc. It can solve problems such as easy to fall off, reduce the reflective effect of materials, and the time of adding glass beads is difficult to control, so as to improve water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

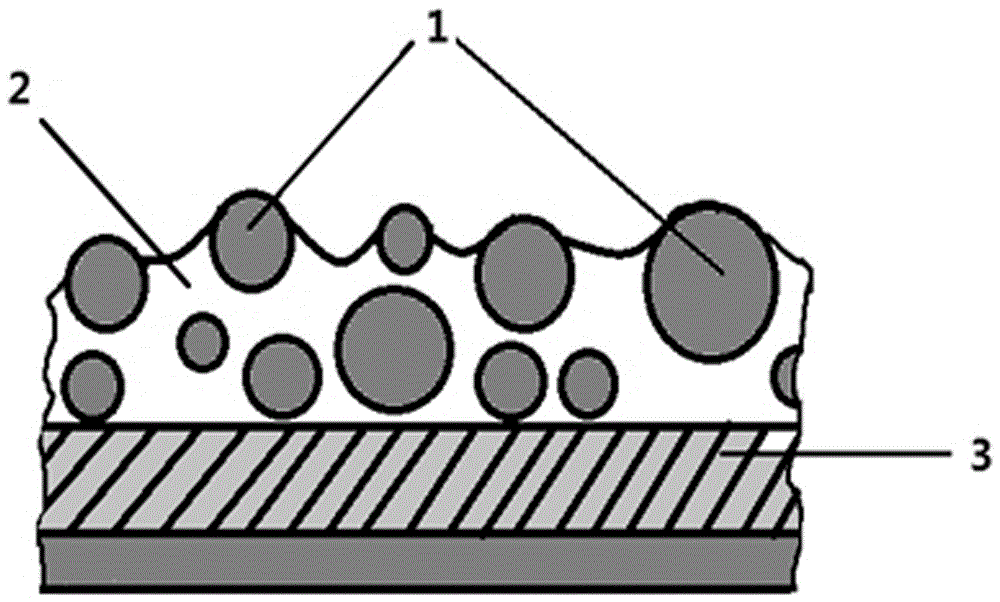

Image

Examples

Embodiment 1

[0024] The preparation method of the road marking patch, the specific steps are as follows.

[0025] Step 1, coating of artificially dyed glass microspheres.

[0026] (1) Preparation of colored polyurethane prepolymer: Take 8 parts by mass of dipropylene glycol and place it in a three-necked flask equipped with an electric mixer, a constant pressure dropping funnel, a thermometer, and a drying tube; depressurize to 0.04MPa at 110°C After removing water for 2 hours, cool naturally to 65°C, add 20 parts by mass of acetone solution with a concentration of 30% for dilution, and simultaneously turn on the electric mixer and stir at 1000 rpm. Then 2 parts by mass of dibutyltin dilaurate are added to the diluent; 20 parts by mass of toluene diisocyanate is diluted with 20 parts by mass of acetone with a concentration of 30%, and all of them are added to the there-necked flask, while adding 10 parts by mass of lead Chrome yellow powder and 6 parts by mass of hydroxy silicone oil were...

Embodiment 2

[0031] (1) Preparation of colored polyurethane prepolymer: Take 7 parts by mass of dipropylene glycol and place it in a three-necked flask equipped with an electric mixer, a constant pressure dropping funnel, a thermometer, and a drying tube; depressurize to 0.03MPa at 110°C After removing water for 2 hours, cool naturally to 65° C., add 30 parts by mass of acetone solution with a concentration of 30% for dilution, and simultaneously turn on the electric mixer and stir at 1500 rpm. Then 3 parts by mass of dibutyltin dilaurate are added to the diluent; 25 parts by mass of toluene diisocyanate is diluted with 30 parts by mass of acetone with a concentration of 30% and then all added to the three-necked flask. Iron yellow powder and 7 parts by mass of hydroxy silicone oil were stirred at 65° C. at 2000 rpm for 15 minutes, and cooled to room temperature to obtain a colored polyurethane prepolymer containing silicon.

[0032] (2) Coating of glass beads: first take 20 parts by mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com