A kind of process method of manufacturing carbon steel gate valve gate

A process method and gate valve technology, which is applied in the field of gate valves, can solve the problems of less than 11.5% Cr content, uneven hardness on the seal, and hardness not up to the standard, so as to increase wear resistance and shorten the production time of products. Cycle, strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

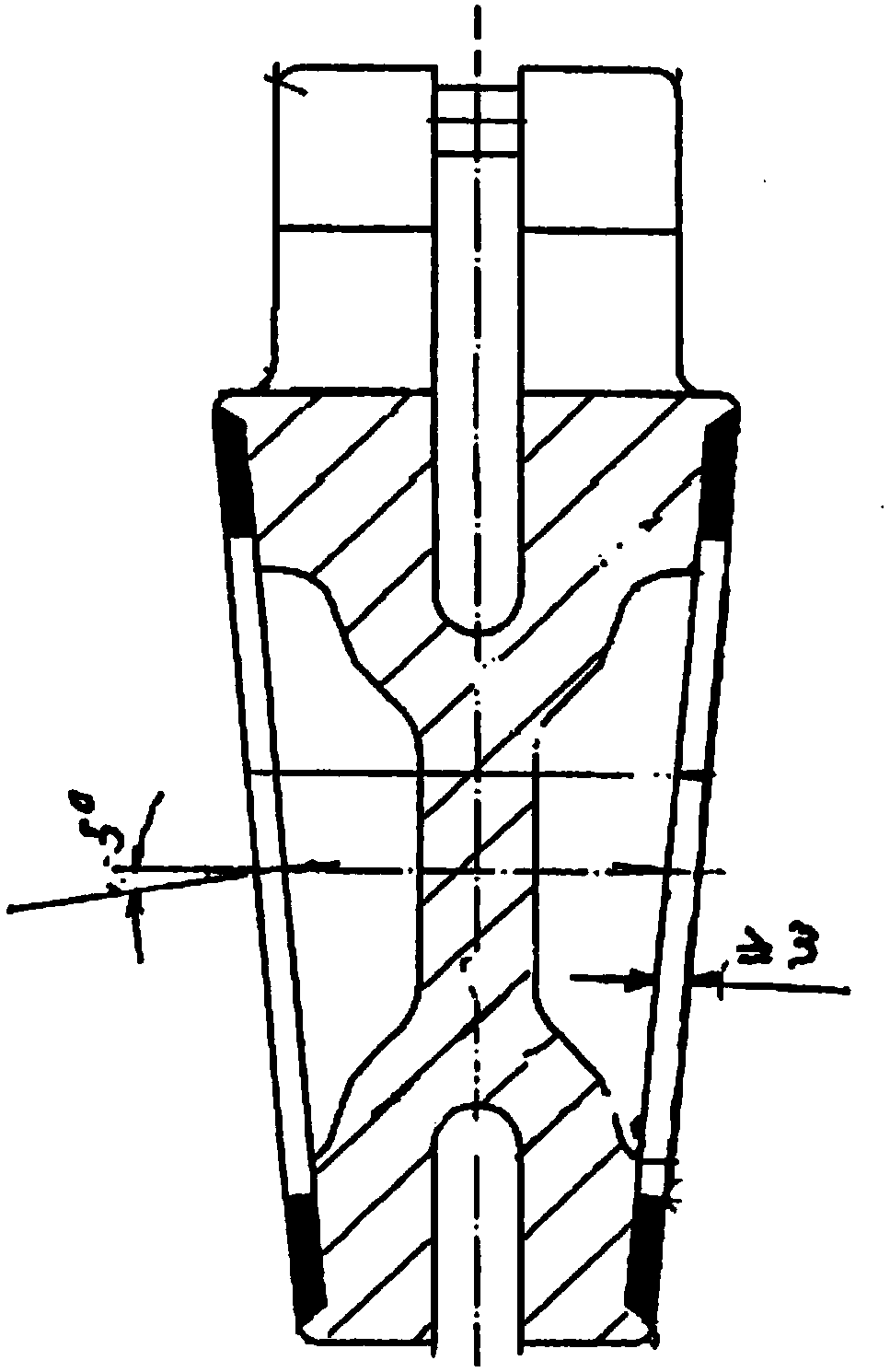

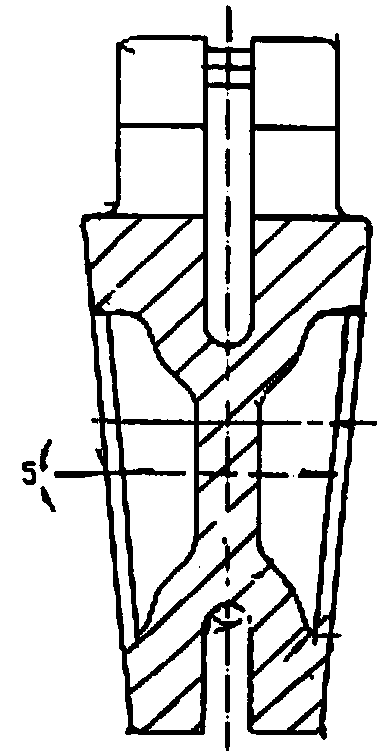

[0025] Such as figure 1 Shown, a kind of technological method of manufacturing carbon steel gate valve disc, which comprises the following steps:

[0026] 1. Select the ASTM A487 / A487M standard CA15 material as the casting material, and the Cr content in the CA15 material is 11.5-14%;

[0027] 2. Cast the casting material selected in step 1 into a gate valve gate;

[0028] 3. After the casting is completed, the gate valve plate is quenched. The quenching temperature is 1030°C±10°C, and the holding time is 2.5min / mm;

[0029] 4. Temper the quenched gate valve gate, the tempering temperature is 460°C±10°C, and the holding time is 3min / mm; 5. Cool the tempered gate valve gate by oil cooling or water cooling, after cooling The Cr content of the gate valve plate is 11.5%-14%, and the hardness is HRC40-42.

[0030] In order to solve the problem of Cr less than 11.5% on the sealing surface of the ram, the hardness is not balanced, and the hardness and other problems, the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com