High-pressure multiphase-flow coupling rock true-triaxial test system and method

A test system and test method technology, applied in the field of high-pressure multiphase flow coupled rock true triaxial test system, can solve the problem that the numerical simulation results cannot meet the engineering requirements and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0072] 1. System

[0073] 1. Overall

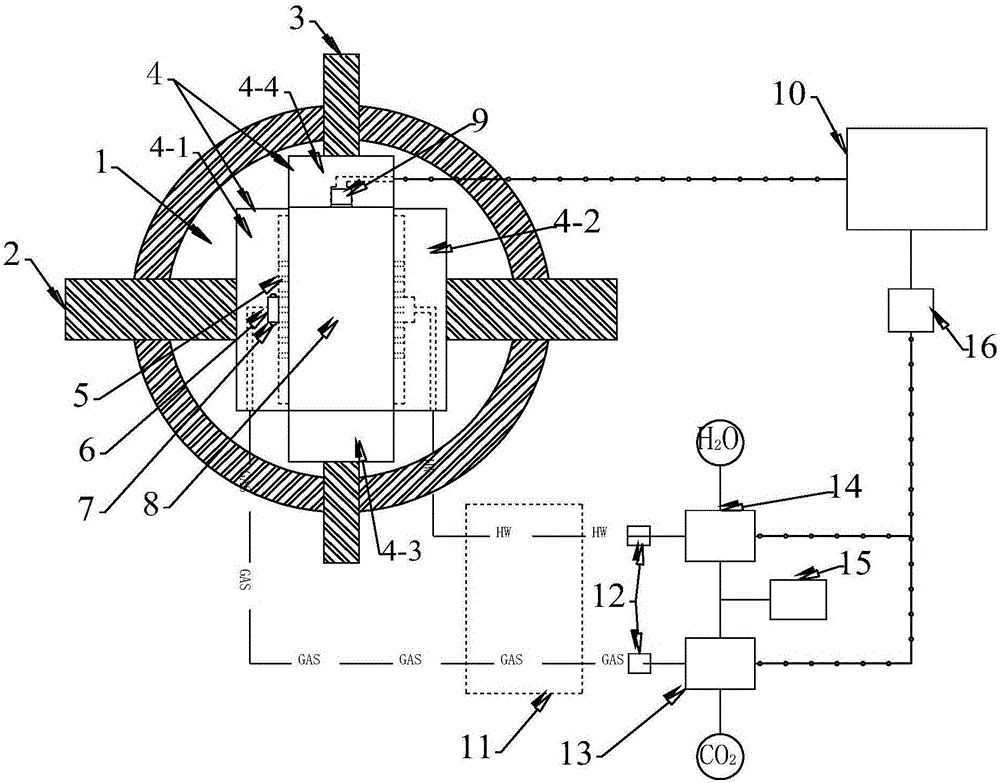

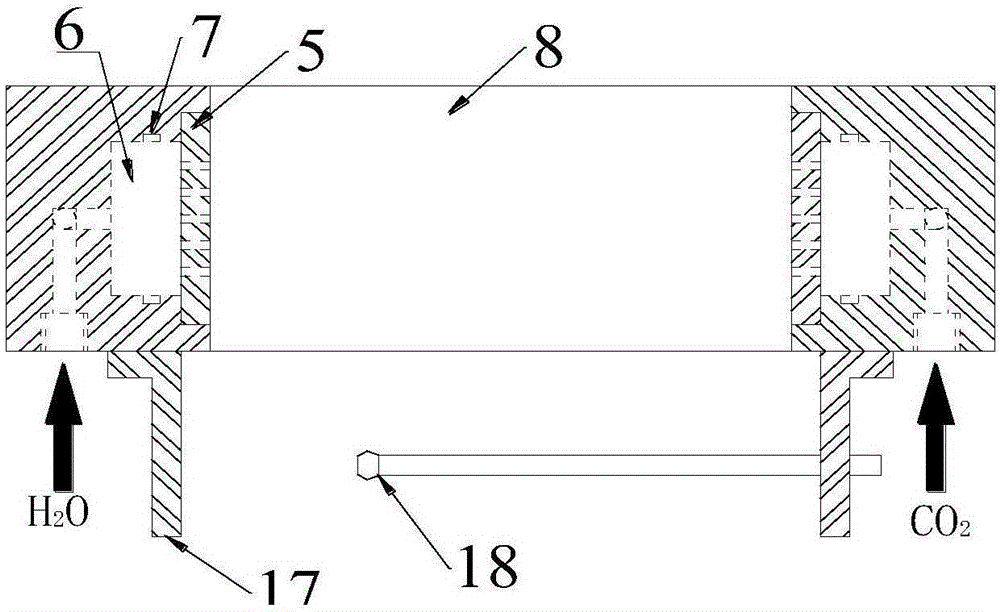

[0074] Such as figure 1 , 2 , the system includes a confining pressure chamber 1, an X-direction finale 2, a Y-direction finale 3, a loading pad 4, a porous partition 5, a Pcmax ceramic plate 6, an O-ring 7, a rock sample 8, an acoustic emission sensor 9, and a computer 10. Temperature regulating water area 11, filter 12, pore carbon dioxide metering pump 13, pore water metering pump 14, vacuum pump 15, controller 16, displacement bracket 17 and LVDT displacement sensor 18;

[0075] Its location and connection relationship are:

[0076] A rock sample 8 is arranged in the center of the confining pressure chamber 1, and a loading block 4 is arranged around the rock sample 8. The pressing shaft 2 in the X direction presses the left and right loading blocks 4-1, 4-2, and the pressing shaft 3 in the Y direction. Compress the front and rear loading p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com