Resistivity testing device capable of regulating temperature, atmosphere and density of powder material

A powder material and testing device technology, applied in the direction of measuring devices, analyzing materials, material resistance, etc., can solve the problems of single test method, need to be improved, not considered, etc., achieve uniform gas distribution, small and convenient equipment structure, fixed Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing

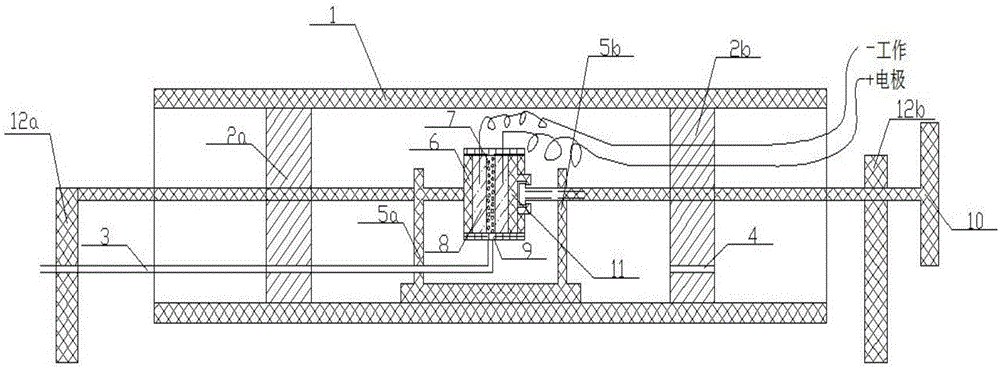

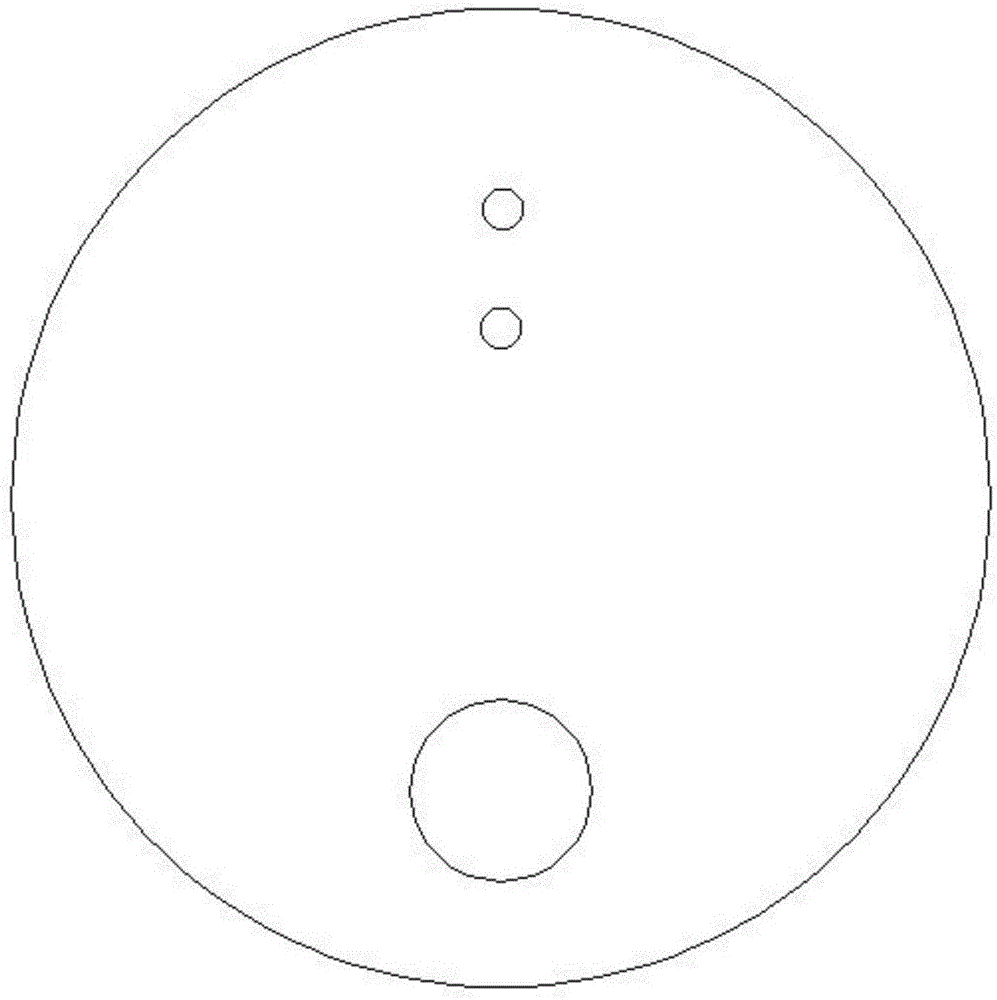

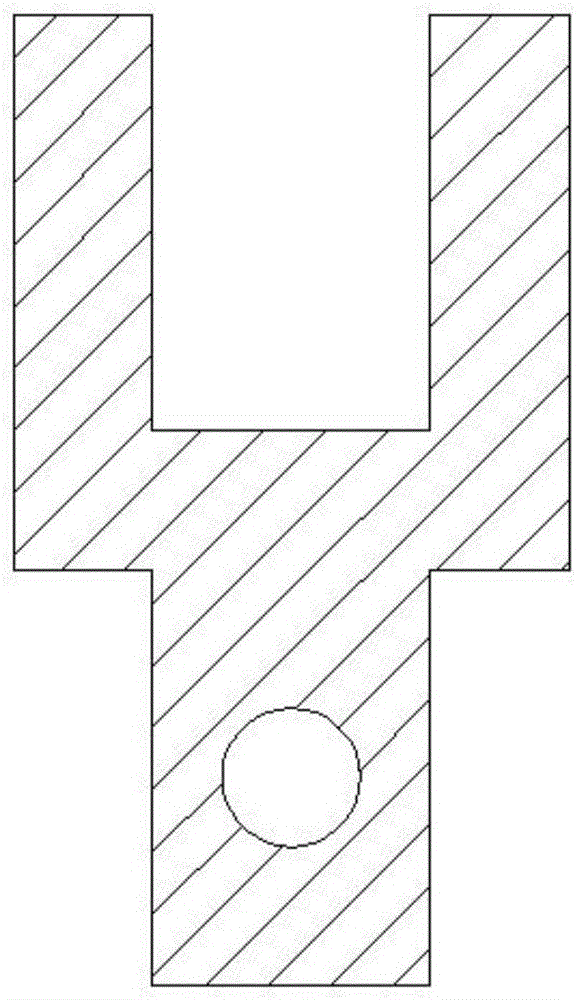

[0026] Such as figure 1 As shown, the structure of a resistivity testing device that can control the temperature, atmosphere and density of the powder material of the present invention is: Al 2 o 3 Sleeve (1), round cake sealing plug with air inlet (2a), round cake sealing plug with air outlet and wire outlet (2b), inlet pipe (3), air outlet (4), Bracket with air inlet (5a), screwed bracket (5b), pressurized storage bin (6), sample powder to be tested (7), electrode (8), deflector Semicircular gas distributor (9), T-shaped screw with thread (10), pressure plate with constriction (11), external fixed bracket with air inlet (12a), external bracket for fixed screw (12b).

[0027] 1) First fill the electrode (8) with wires and the sample powder (7) to be tested into the pressurized storage bin (6).

[0028] 2) Turn the threaded T-screw (10) to compact the sample to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com