Carrier storage type grooved-gate IGBT (insulated gate bipolar transistor)

A carrier storage and trench gate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of insignificant improvement in device performance and reduced device withstand voltage, so as to improve the withstand voltage capability and improve the trade-off relationship. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

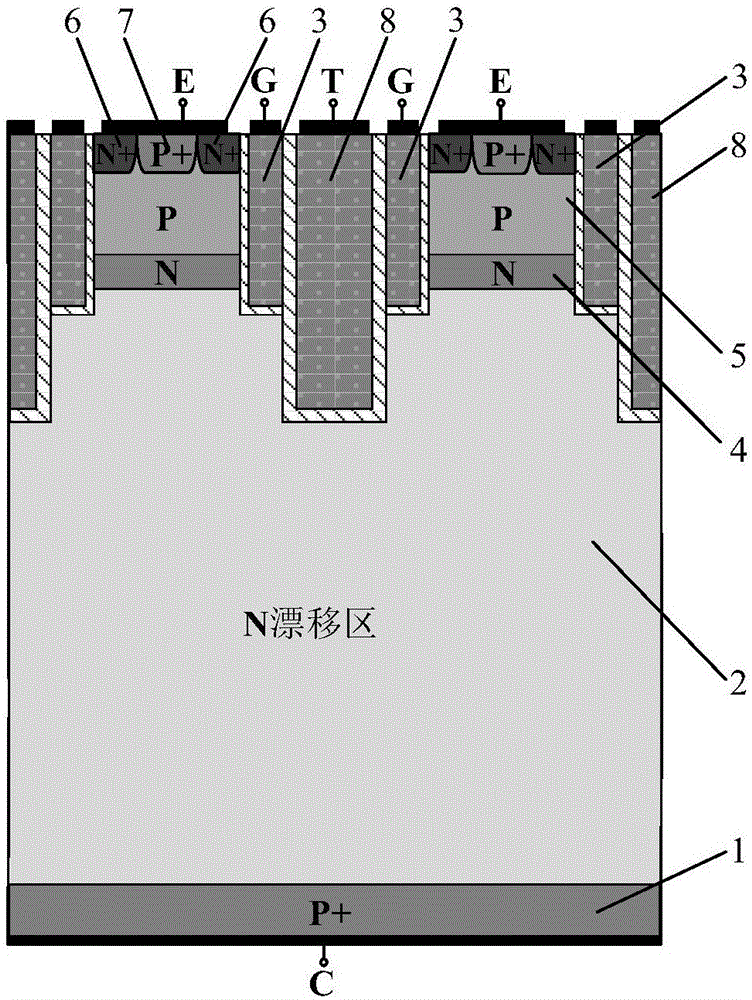

[0025] Such as figure 1 As shown, this example includes a P+ collector region 1, an N drift region 2, a groove gate structure 3 and an emitter active region, and the groove gate structure 3 and the emitter active region are alternately arranged on the surface of the N drift region (2) , the emitter active region is sequentially composed of an N storage layer 4, a P-type body region 5, and an emitter doped region from bottom to top, the bottom of the N storage layer 4 is higher than the bottom of the trench gate structure 3, and the emitter The doped region is composed of N+ regions 6 on both sides and a P+ region 7 between the two N+ regions 6. It is characterized in that it also includes a deep groove structure 8, which is composed of the medium of the groove wall and the P+ region 7. The conductive material surrounded by it, the deep groove structure 8 runs through the entire groove gate structure 3 from the surface of the groove gate structure 3 and goes deep into the insid...

Embodiment 2

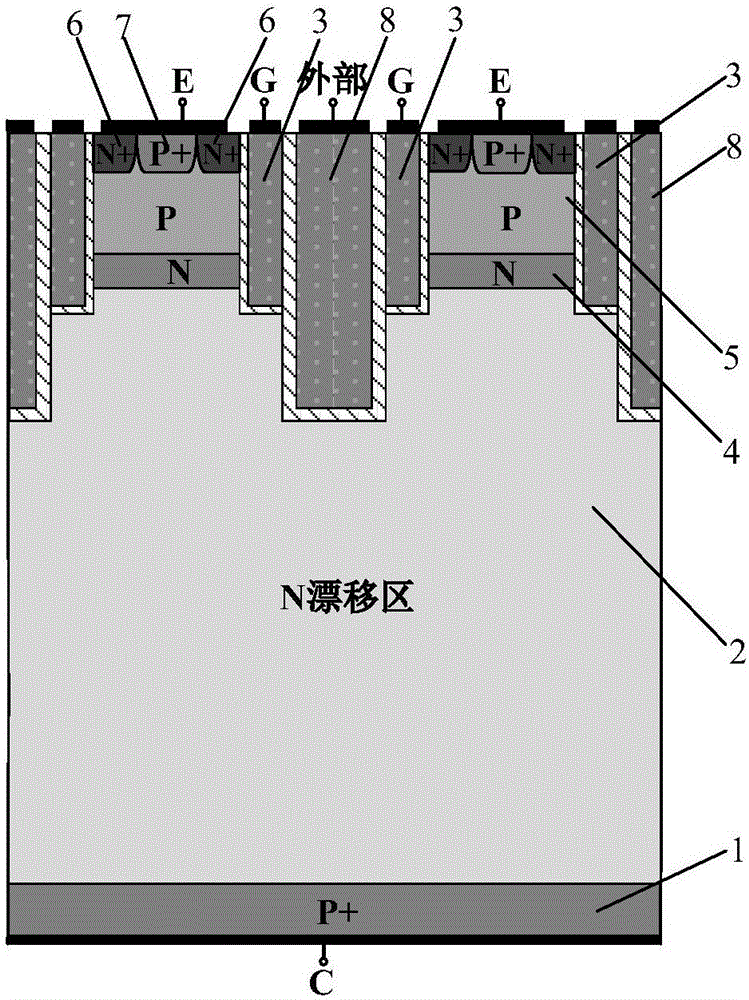

[0029] Such as figure 2 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, except that the deep groove structure 8 is connected to the emitter electrode through a conductive material instead of being connected to an external variable electrode.

[0030] This example works as follows:

[0031] When the device is in forward conduction, the deep groove structure 8 at low potential can accumulate a layer of holes on the surface to enhance the conductance modulation effect, thereby further reducing the conduction voltage drop. In addition, since the deep groove structure is connected to the emitter, there is basically no influence on the "gate-collector" capacitance (that is, "Miller capacitance") of the device; The beneficial effects are the same.

[0032] As a simple modification of this embodiment, the deep trench structure 8 can also be connected to the gate electrode through a conductive material, which can also improve the withstand volta...

Embodiment 3

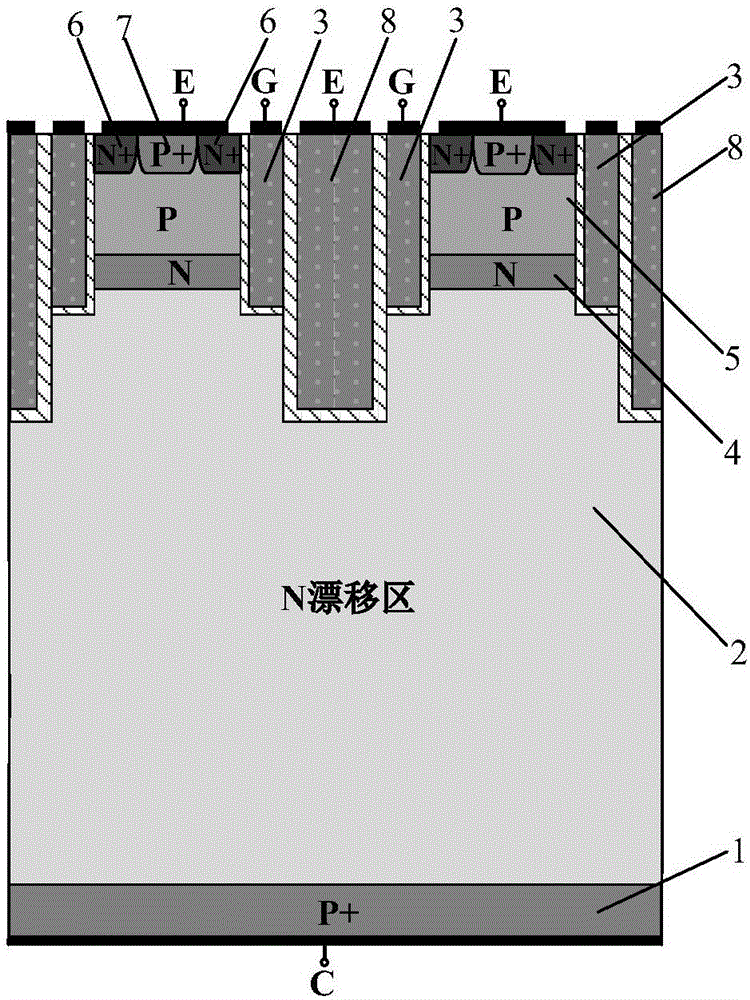

[0034] Such as image 3 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, except that there is an N-type buffer layer 9 above the P+ collector region 1 , and the concentration of this buffer layer is higher than that of the N-type drift region 2 .

[0035] In addition to the beneficial effects described in Embodiment 1, this example has a punch-through withstand voltage structure due to the existence of the N-type buffer layer 9, which can make the device have a shorter drift region length under the same withstand voltage capability. , reduces the resistance of the drift region in the on-state of the device, and can also control the hole injection efficiency of the P+ collector 1 in the forward conduction, thereby further reducing the on-state voltage drop and off-state loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com