Preparation method of fermentation vinegar egg juice

A vinegar-egg liquid, fermentation type technology is applied in the directions of bacteria used in food preparation, the function of food ingredients, bifidobacteria, etc., and can solve problems such as unfavorable popularization of health care products, irregular production process, high cholesterol content and the like, To achieve the effect of improving immunity, improving human health and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

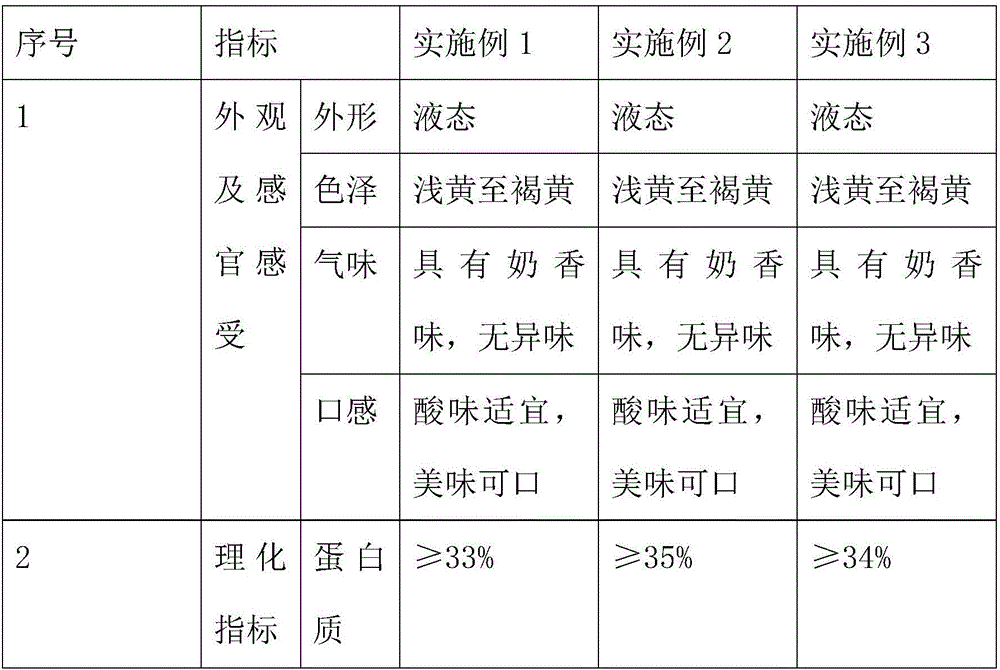

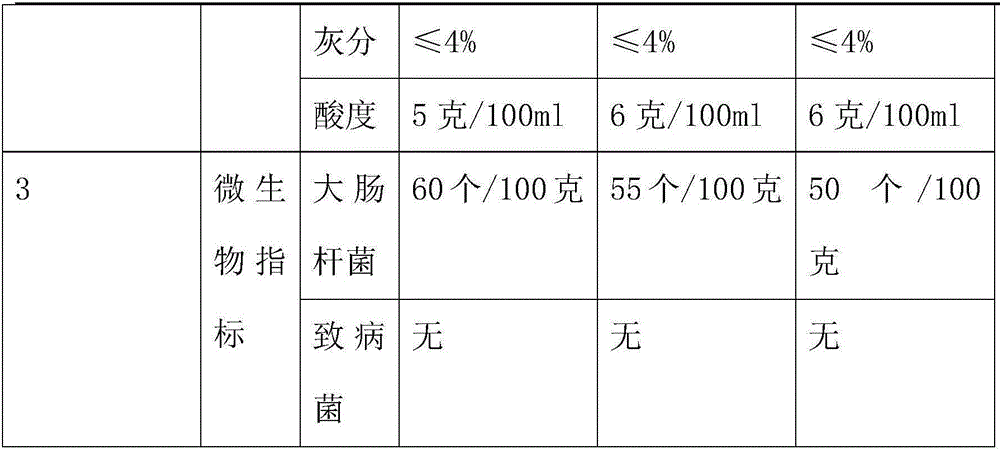

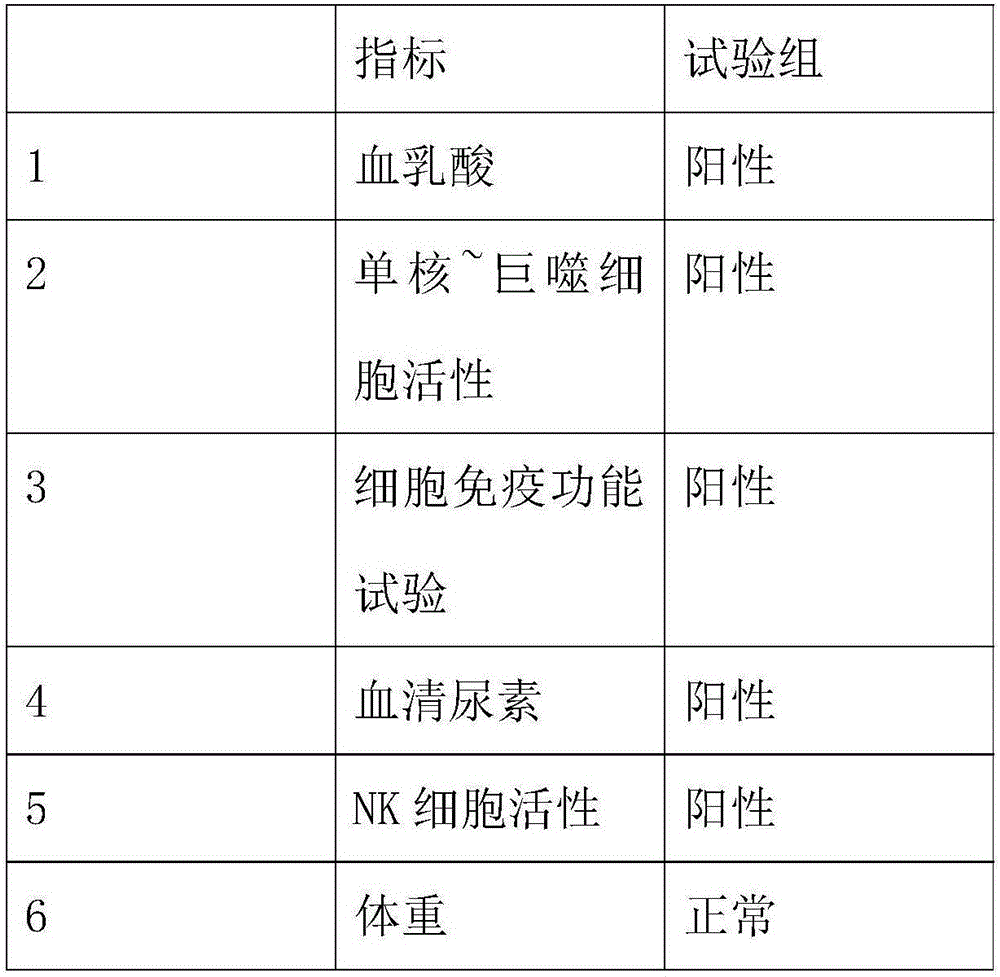

Examples

Embodiment 1

[0034] A kind of preparation method of fermented vinegar egg liquid of the present invention, comprises the steps:

[0035] (1) Egg liquid preparation: select fresh poultry eggs, wash them, soak them in 10 mg / kg chlorine water for 10 minutes for disinfection, break and separate the egg shells, collect the egg liquid, and stir evenly.

[0036] (2) Mix homogeneously; mix the homogeneously stirred egg liquid, milk, and white granulated sugar in a ratio of 60:20:8, and homogenize at 20MPa.

[0037] (3) Sterilization and cooling: sterilize the homogenized mixed raw materials at 70°C for 2 minutes, and cool to 40°C.

[0038] (4) Inoculation and fermentation; add the bacterium powder of lactic acid bacteria in the mixed raw material after cooling, and cultivate and ferment for 3h at 43°C; the quality of the bacterium powder of the lactic acid bacteria is 0.5% of the fermentation mixed liquid quality; the lactic acid bacteria are A combination of four of Lactobacillus acidophilus, St...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the preparation method of a kind of fermented vinegar egg liquid of the present invention comprises the following steps:

[0049] (1) Egg liquid preparation: select fresh poultry eggs, wash them, soak them in 10 mg / kg chlorine water for 10 minutes for disinfection, break and separate the egg shells, collect the egg liquid, and stir evenly.

[0050] (2) Mix homogeneously; mix the homogeneously stirred egg liquid, milk, and white granulated sugar in a ratio of 70:15:10, and homogenize at 20 MPa.

[0051] (3) Sterilization and cooling: sterilize the homogenized mixed raw materials at 80°C for 20 minutes, and cool to 42°C.

[0052] (4) inoculation and fermentation; the bacterium powder of the lactic acid bacteria that adds in the mixed raw material after cooling, and cultivate and ferment 5h at 40 ℃; The quality of the bacterium powder of described lactic acid bacteria is 2.5% of the fermentation mixed liquor qual...

Embodiment 3

[0062] The difference between embodiment 3 and embodiment 1 is that the preparation method of a kind of fermented vinegar egg liquid of the present invention comprises the following steps:

[0063] (1) Egg liquid preparation: select fresh poultry eggs, wash them, soak them in 10 mg / kg chlorine water for 10 minutes for disinfection, break and separate the egg shells, collect the egg liquid, and stir evenly.

[0064] (2) Mix homogeneously; mix the homogeneously stirred egg liquid, milk, and white granulated sugar in a ratio of 80:30:5, and homogenize at 20MPa.

[0065] (3) Sterilization and cooling: sterilize the homogenized mixed raw materials at 55°C for 30 minutes, and cool to 45°C.

[0066] (4) inoculation and fermentation; the bacterium powder of the lactic acid bacteria that adds in the mixed raw material after cooling, and cultivate and ferment 6h at 45 ℃; The quality of the bacterium powder of described lactic acid bacteria is 4% of the fermentation mixed liquor quality;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com