Manufacturing method of oil-water separation metal mesh having super-hydrophilicity/underwater super-lipophobicity

A technology of oil-water separation and manufacturing method, which is applied in the direction of separation method, liquid separation, chemical instruments and methods, etc., and can solve the problems of complicated manufacturing process of oil-water separation mesh or oil-water separation mesh, inability to prepare large areas, and use of harmful solvents, etc. Achieve the effects of easy cleaning and reuse, simple manufacturing process and equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

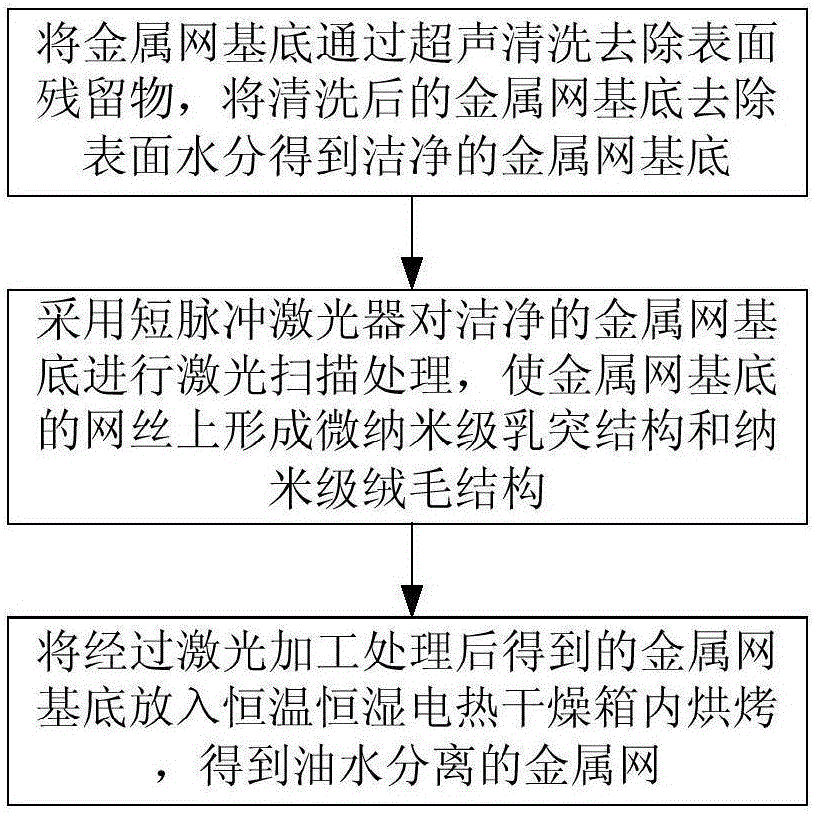

[0034] The preparation method of the oil-water separation stainless steel mesh with superhydrophilic / underwater superoleophobicity comprises the following steps:

[0035] Step 1: Place the stainless steel mesh substrate with a mesh number of 50-1000 mesh in an ultrasonic cleaner filled with acetone, absolute ethanol and deionized water for 10 minutes to remove surface residues. The ultrasonic frequency is 20-40KHz. The power range is 100-150W. After cleaning, the stainless steel mesh base is blown dry with cold wind or air-dried at room temperature to obtain a clean stainless steel mesh base;

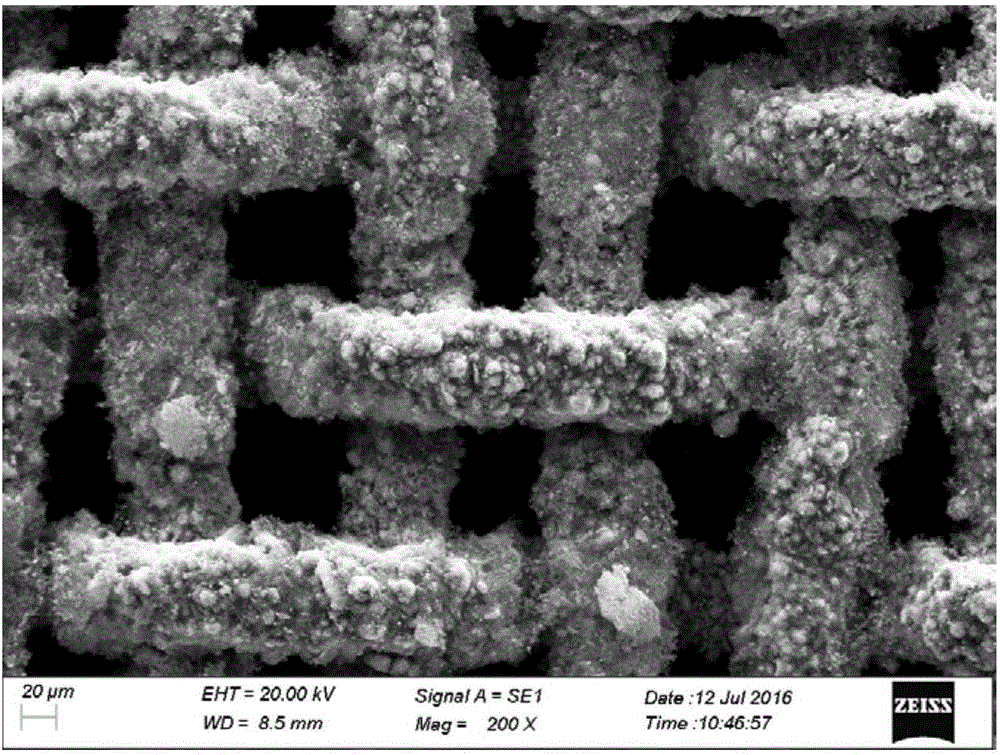

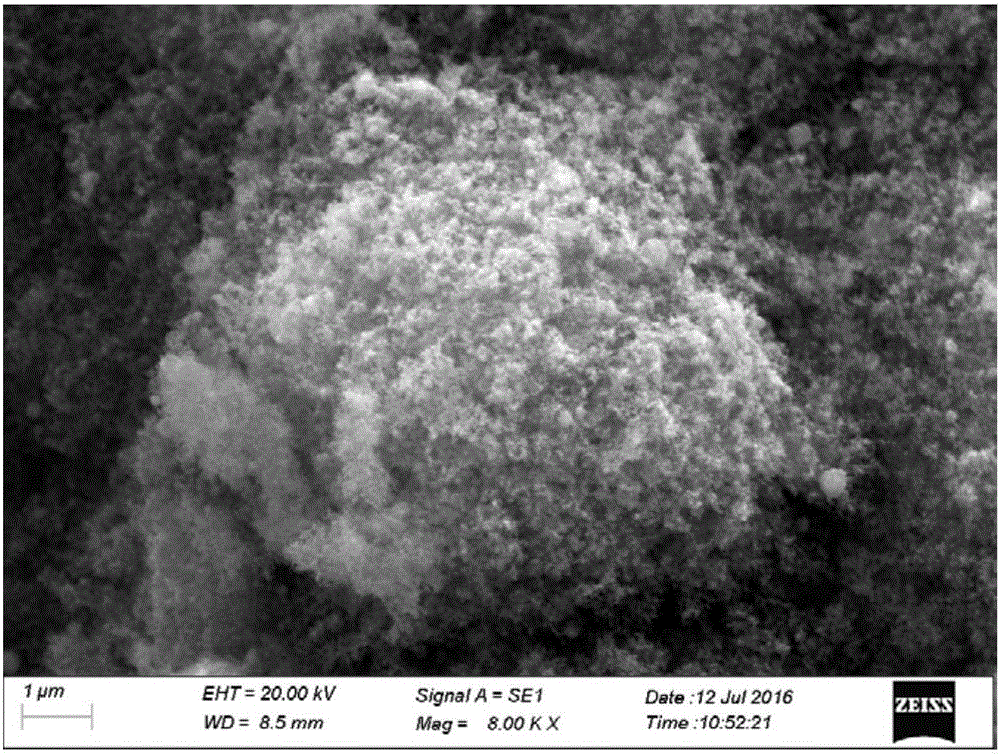

[0036] Step 2: Use laser processing technology to scan and process the clean stainless steel mesh substrate obtained in step 1 with a laser beam with a wavelength of 570-1064nm and an average power of less than 300W; the scanning range, scanning trajectory and processing speed of the laser are all controlled by the computer Program control and setting, after adjusting the relevant proce...

Embodiment 2

[0042] The preparation method of the oil-water separation copper mesh with superhydrophilic / underwater superoleophobicity comprises the following steps:

[0043] Step 1: Place the copper mesh substrate with a mesh number of 50-1000 mesh in an ultrasonic cleaner filled with acetone, absolute ethanol and deionized water for 10 minutes to remove surface residues. The ultrasonic frequency is 20-40KHz. The power range is 100-150W. After cleaning, the copper mesh substrate is blown dry with cold wind or air-dried at room temperature to obtain a clean copper mesh substrate;

[0044] Step 2: Using laser processing technology, using a laser beam with a wavelength of 570-1064nm and an average power of less than 300W to perform laser scanning processing on the clean copper mesh substrate obtained in step 1; the scanning range, scanning trajectory and processing speed of the laser are all controlled by the computer Program control and setting, after adjusting the relevant process paramete...

Embodiment 3

[0049] A preparation method of an oil-water separation titanium mesh with superhydrophilicity / underwater superoleophobicity, comprising the following steps:

[0050] Step 1: Place the titanium mesh substrate with a mesh number of 50-1000 mesh in an ultrasonic cleaner filled with acetone, absolute ethanol and deionized water for 10 minutes to remove surface residues. The ultrasonic frequency is 20-40KHz. The power range is 100-150W. After cleaning, dry the titanium mesh base with cold wind or dry it naturally at room temperature to obtain a clean titanium mesh base;

[0051] Step 2: Using laser processing technology, using a laser beam with a wavelength of 570-1064nm and an average power of less than 300W to perform laser scanning processing on the clean titanium mesh substrate obtained in step 1; the scanning range, scanning trajectory and processing speed of the laser are all controlled by the computer. Program control and setting, after adjusting the relevant process paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com