In-situ preparation method of photocatalyst strontium bismuth niobium oxide containing oxygen vacancy defect

A photocatalyst and vacancy defect technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of increasing the cost of oxygen vacancy defects and difficult process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Weigh SrCO at a molar ratio of 1:1:1 3 , Bi 2 o 3 ,Nb 2 o 5 , and then press SrBi 2 Nb 2 o 9 The total mass ratio of nanosheets, NaCl, and KCl is 1:1. Weigh NaCl and KCl, put the weighed raw materials in an agate mortar and grind for 40 minutes, and then place the ground raw materials in a tube furnace for calcination. , the calcination temperature is 800°C, and the time is 3h. After the reaction, the obtained sample is washed with deionized water, and the method of suction filtration and washing is adopted until the filtrate is neutral, and then the washed sample is placed in a blast drying oven. Dry at 80°C for 2h to obtain SrBi 2 Nb2 o 9 Nanosheets;

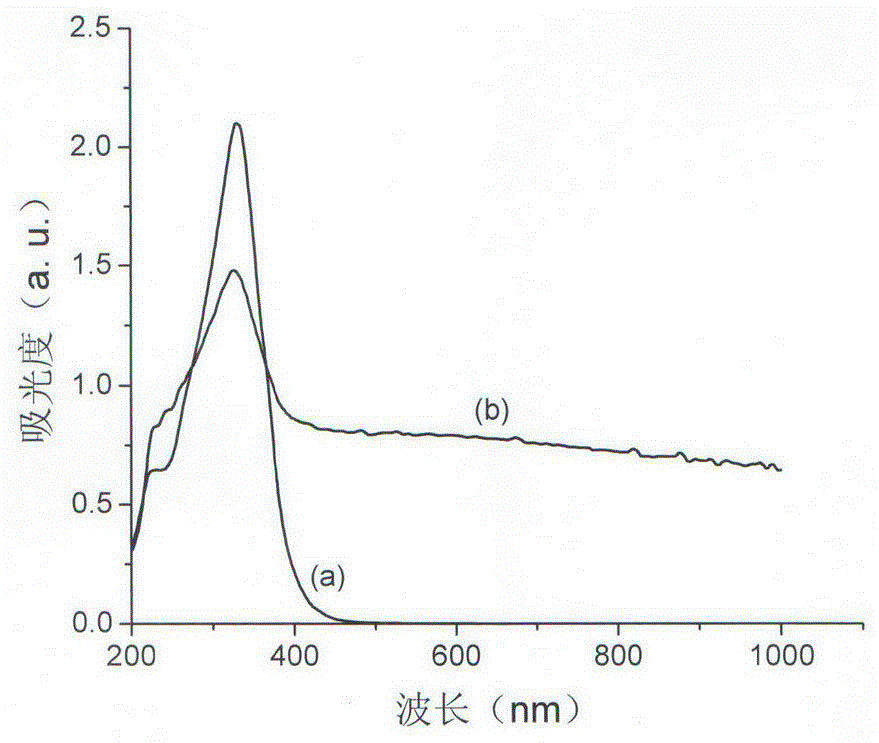

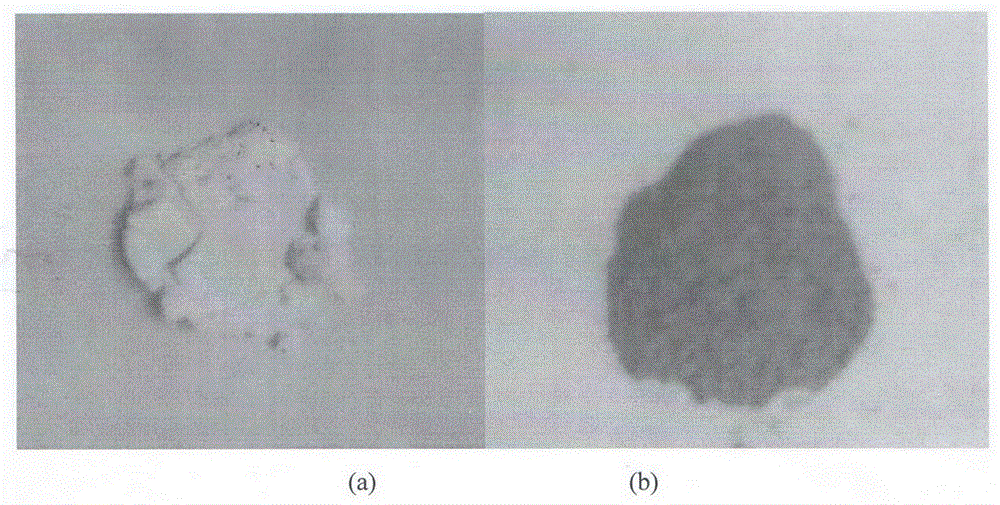

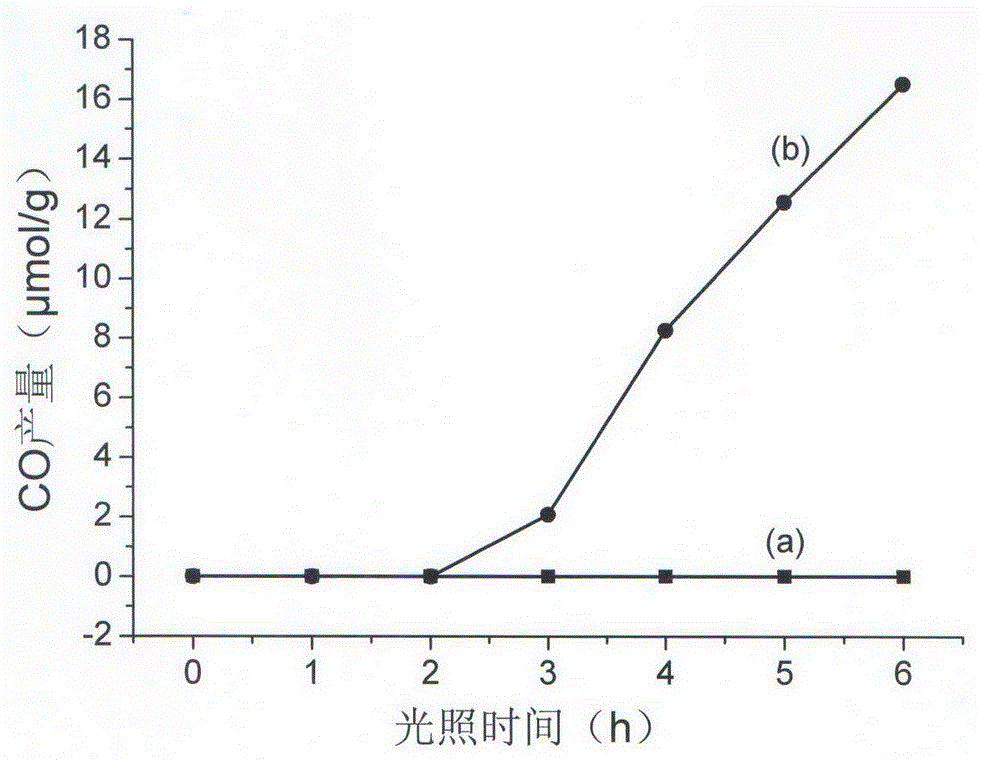

[0022] b, weigh the SrBi obtained in step a 2 Nb 2 o 9 20 mg of nanosheets were placed in a glass petri dish with a diameter of 60 mm, and 2 ml of deionized water was added dropwise to ultrasonically disperse evenly, then the petri dish was placed in a drying oven, and dried at 80°C for 60 minutes to remo...

Embodiment 2

[0025] a. Weigh SrCO at a molar ratio of 1:1:1 3 , Bi 2 o 3 ,Nb 2 o 5 , and then press SrBi 2 Nb 2 o 9 The total mass ratio of nanosheets, NaCl, and KCl is 1:10. Weigh NaCl and KCl, put the weighed raw materials in an agate mortar and grind for 40 minutes, and then place the ground raw materials in a tube furnace for calcination. , the calcination temperature is 1000°C, and the time is 3h. After the reaction, the obtained sample is washed with deionized water, and the method of suction filtration and washing is adopted until the filtrate is neutral, and then the washed sample is placed in a blast drying oven. Dry at 80°C for 2h to obtain SrBi 2 Nb 2 o 9 Nanosheets;

[0026] b, weigh the SrBi obtained in step a 2 Nb 2 o 9 Put 50 mg of nanosheets in a glass petri dish with a diameter of 60 mm, add 2 ml of deionized water to disperse evenly by ultrasonic, then put the petri dish in a drying oven, and dry at 200°C for 60 minutes to remove water molecules adsorbed on t...

Embodiment 3

[0029] a. Weigh SrCO at a molar ratio of 1:1:1 3 , Bi 2 o 3 ,Nb 2 o 5 , and then press SrBi 2 Nb 2 o 9 The total mass ratio of nanosheets, NaCl, and KCl is 1:5. Weigh NaCl and KCl, put the weighed raw materials in an agate mortar and grind for 40 minutes, and then place the ground raw materials in a tube furnace for calcination. , the calcination temperature is 1200°C, and the time is 3h. After the reaction, the obtained sample is washed with deionized water, and the method of suction filtration and washing is adopted until the filtrate is neutral, and then the washed sample is placed in a blast drying oven. Dry at 80°C for 2h to obtain SrBi 2 Nb 2 o 9 Nanosheets;

[0030] b, weigh the SrBi obtained in step a 2 Nb 2 o 9 100 mg of nanosheets were placed in a glass petri dish with a diameter of 60 mm, and 2 ml of deionized water was added dropwise to ultrasonically disperse evenly, then the petri dish was placed in a drying oven, and dried at 150°C for 60 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com