Preparation method of rice seedling raising substrate

A rice seedling raising and substrate technology, applied in botany equipment and methods, preparation of organic fertilizers, soilless cultivation, etc., can solve resource consumption and other problems, achieve the effect of avoiding resource consumption and alleviating the shortage of grass carbon soil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

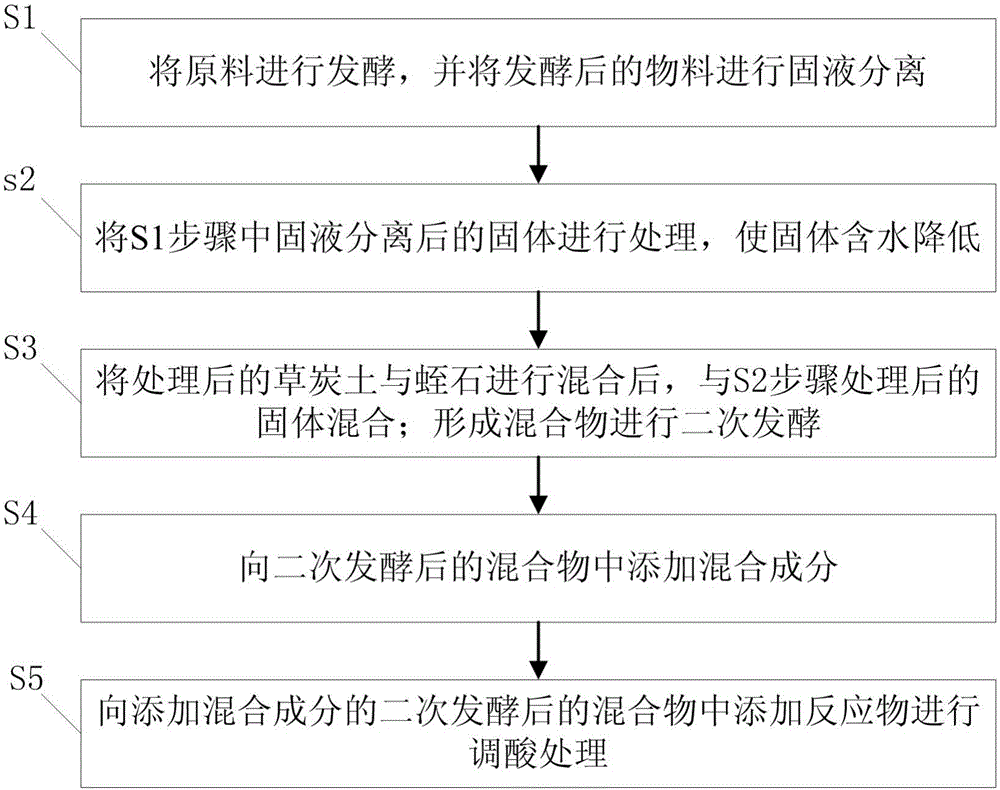

[0037] Such as figure 1 Shown, the present invention proposes a kind of rice seedling raising matrix preparation method, comprises the steps:

[0038] Ferment the raw material, and separate the solid and liquid from the fermented material; in the present invention, it is preferred to subject cow dung to anaerobic fermentation, and separate the solid and liquid from the fermented material to separate the solid and liquid; specifically The cow dung is subjected to anaerobic fermentation for 30-40 days, and the fermented material is subjected to solid-liquid separation twice to separate biogas residue and biogas slurry; manure is fermented;

[0039] The solid after solid-liquid separation is treated to reduce the water content of the solid; in the present invention, the biogas residue after solid-liquid separation is preferably treated to reduce the water content of the biogas residue to 40%-50%. Specifically, the biogas residue after solid-liquid separation is processed to red...

Embodiment 1

[0044] Anaerobic fermentation of fresh cow dung for 30 days, and solid-liquid separation of the fermented material twice to separate biogas residue and biogas slurry;

[0045] Treat the biogas residue after solid-liquid separation to reduce the water content of the biogas residue to 40%, and take 400 parts for use;

[0046] After mixing peat soil and vermiculite in the ratio of 2:1 for drying and crushing and sieving, 476 parts are mixed with the treated solid to form a mixture, and carry out secondary fermentation for 15 days;

[0047] Add 11 parts of organic-inorganic compound fertilizer, 1 part of silicon dioxide, 0.5 part of copper sulfate and 1 part of Bacillus subtilis to the mixture after secondary fermentation;

[0048] Add 10.5 parts of furfural to the mixture after the secondary fermentation of the mixed components to carry out acid adjustment treatment; and then form the required matrix.

Embodiment 2

[0050] The fresh cow dung is subjected to anaerobic fermentation for 32 days, and the fermented material is subjected to solid-liquid separation twice to separate biogas residue and biogas slurry;

[0051] Treat the biogas residue after solid-liquid separation to reduce the water content of the biogas residue to 45%, and take 430 parts for use;

[0052] After mixing peat soil and vermiculite in a ratio of 2.3:1, air-dried, crushed and sieved, 500 parts were mixed with the treated solid to form a mixture, and secondary fermentation was carried out for 15 days;

[0053] Add 11 parts of organic-inorganic compound fertilizer, 1 part of silicon dioxide, 0.5 part of copper sulfate and 1 part of Bacillus subtilis to the mixture after secondary fermentation;

[0054] Add 10.5 parts of furfural to the mixture after the secondary fermentation of the mixed components to carry out acid adjustment treatment; and then form the required matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com