Composite materials and their preparation methods, applications, insulating wall connectors and rods

A composite material and polymer technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as the optimization of mechanical properties is rarely involved, the optimization of core performance of connectors is rarely involved, and the physical properties of connectors are difficult to achieve. , to achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] According to one embodiment, the present invention relates to a composite material, including a cured product of a resin composition and a reinforcing fiber material. The reinforcing fiber material is in the cured product of the resin composition.

[0046] Raw material consumption also can be controlled according to the scheme of the present invention. In order to further realize the reasonable mutual matching among the various components and make the performance of the composite material better, the dosage is more optimal: by weight, the reinforcing fiber material in the final product is 70-80% and the resin composition is 20-30%. For example, the reinforcing fiber material can also be selected from 71%, 72%, 73%, 74%, 75%, 78%, 80% and so on. The amount of the resin composition can also be selected from 21%, 22%, 24%, 26%, 28%, 30% and so on.

[0047] It is worth noting that one key point of the solution of the present invention is to use a specific thermosetting re...

Embodiment 1

[0126] The preparation method of the composite material is as follows, and the raw materials are all in parts by weight:

[0127] 1) Pass the glass fiber yarn (4800Tex) through the creel, the glue dipping tank, the preforming mold, and finally pass through the thermoforming mold, pass the upper and lower layers of polyester surface mat through the felt guide, the preforming mold, and import Arriving and finally passing through the thermoforming mold, adjusting the count of the fiber yarn so that the glass fiber content of the final product is 80%, and the content of the resin composition in the final product is 20%;

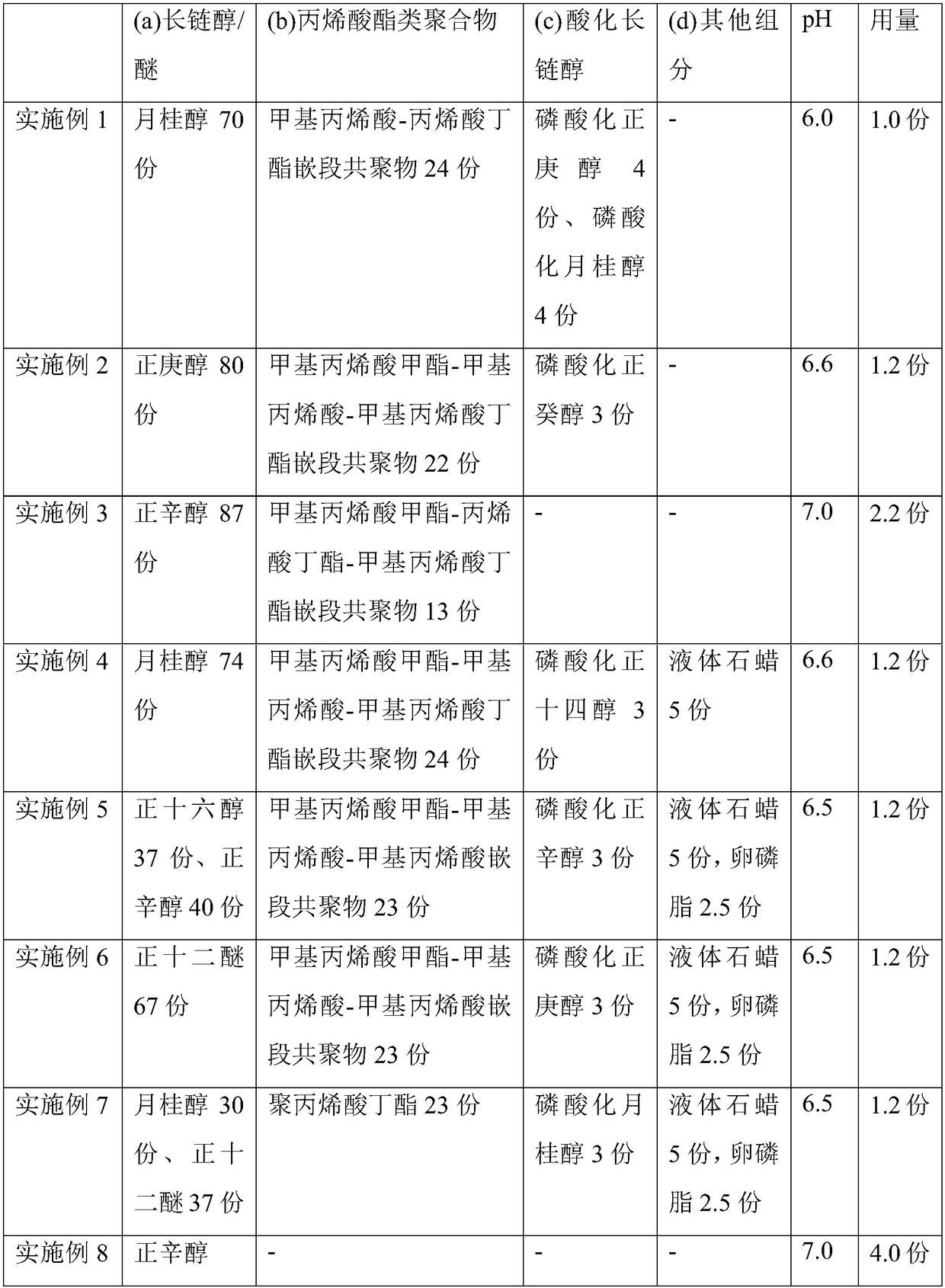

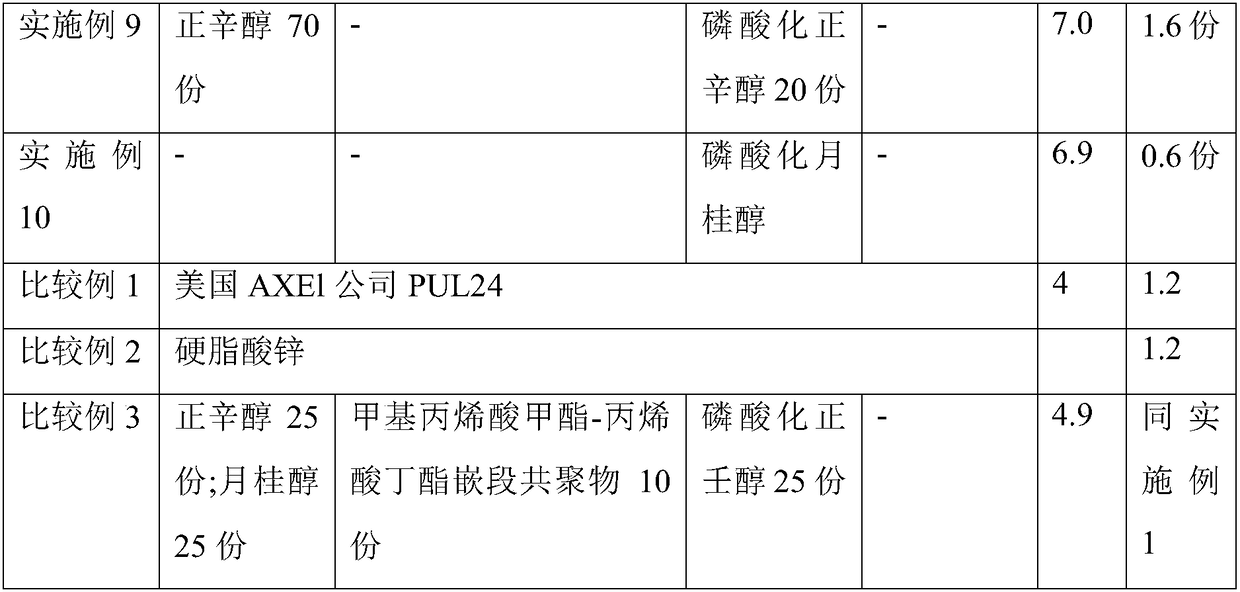

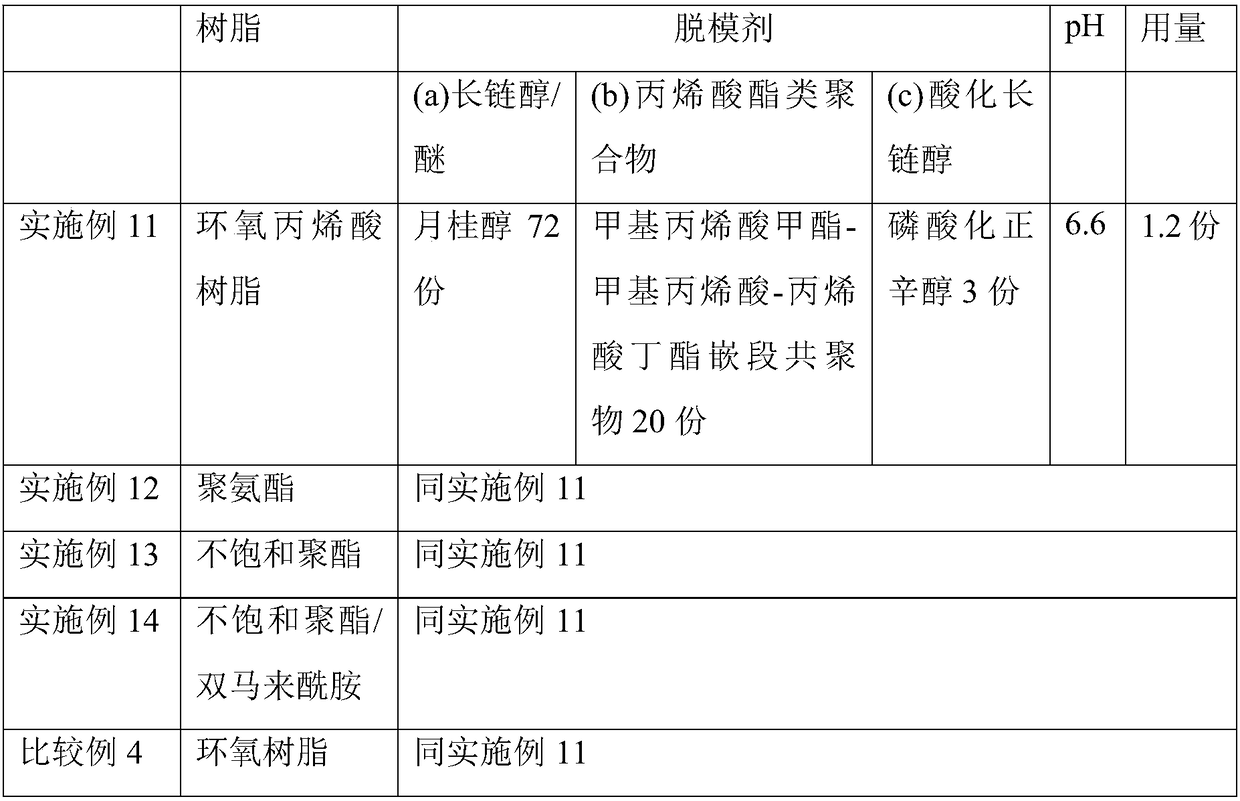

[0128] 2) The configuration of the resin composition is carried out according to the following components: 100 parts by weight of epoxy acrylic resin, 1.0 parts by weight of a composite release agent with a pH value of 6.0, and 15 parts by weight of other auxiliary agents (comprising initiator TBPO / TBPB composite 3 parts by weight, 5 parts by weight of talcum pow...

Embodiment 2

[0133] Other operating steps are basically the same as in Example 1, except that the composite release agent consists of: 80 parts by weight of n-heptanol, methyl methacrylate-methacrylic acid-butyl methacrylate block copolymer (three kinds of The molar ratio of monomer units is: methyl methacrylate: methacrylic acid: butyl methacrylate = 2:1:1.5, number average molecular weight 35000) 22 parts by weight, phosphorylated n-decyl alcohol 3 parts by weight. The pH value of the composite release agent was tested to be 6.6, and the fraction in the resin composition was 1.2 parts by weight. The surface of the sample is always smooth during the production process, without cracks, slag and missing corners, indicating that the release agent has a good effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com