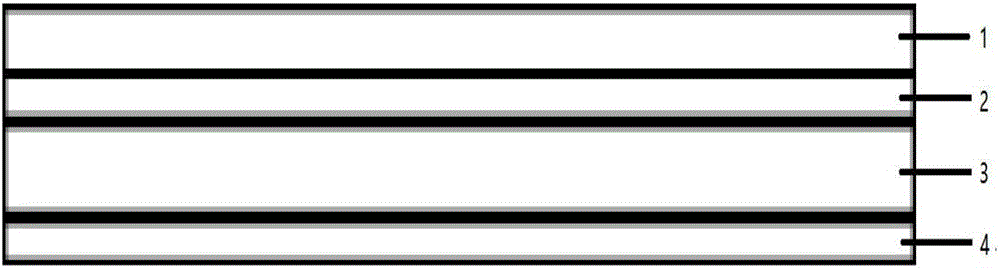

Adhesive tape specially used for three-dimensional (3D) printing

A 3D printing, tape technology, applied in the direction of adhesive, adhesive type, acrylonitrile butadiene styrene polymer adhesive, etc., can solve the problem of product warping, product damage, and product sticking platform that is not easy to remove and other problems, to achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1

[0040] Embodiment 1 one, adhesive glue A preparation

[0041] Described adhesive glue A weight part formula is:

[0042] ABS (acrylonitrile-butadiene-styrene copolymer) 10 kg

[0043] Butyl acetate 25 kg

[0044] Dichloromethane 7 kg

[0045] Polyacrylamide 15 kg

[0046] Polyethylene glycol 8 kg

[0047] Carboxyethyl cellulose 15 kg

[0048] Polyacrylate 20 kg.

[0049] Adhesive A preparation steps: sequentially add ABS, butyl acetate, dichloromethane into the reaction kettle with stirring device, stir at 60r / min for 2min, then raise the temperature to 80°C, then add polyacrylamide, kg polyethylene glycol and carboxyethyl cellulose, stirred for 20 minutes, then vacuumed and defoamed to obtain composite glue; then polyacrylate was added into the reaction kettle, stirred and heated to 110°C, added composite glue, stirred for 5 minutes, and cooled naturally Get Adhesive A. It has been determined that the melt viscosity of the adhesive A prepared in this example is 2. 35 / ...

Embodiment 2

[0069] 1. Preparation of Adhesive Adhesive A

[0070] Described adhesive glue A weight part formula is:

[0071] ABS (acrylonitrile-butadiene-styrene copolymer) 12 kg

[0072] Butyl acetate 25 kg

[0073] Dichloromethane 10kg

[0074] Polyacrylamide 15 kg

[0075] Polyethylene glycol 5 kg

[0076] Carboxyethyl cellulose 15 kg

[0077] Polyacrylate 18 kg.

[0078] Adhesive glue A preparation steps: sequentially add ABS, butyl acetate, dichloromethane into the reaction kettle with stirring device, stir at 40r / min for 2min, then raise the temperature to 65°C, then add polyacrylamide, Polyethylene glycol and carboxyethyl cellulose were stirred for 16 minutes, then vacuumed and degassed to obtain a composite glue; then polyacrylate was added to the reaction kettle, stirred and heated to 125°C, the composite glue was added, stirred for 5 minutes, and naturally cooled to obtain Adhesive A. It has been determined that the melt viscosity of the adhesive A prepared in this example...

Embodiment 3

[0098] 1. Preparation of Adhesive Adhesive A

[0099] Described adhesive glue A weight part formula is:

[0100] ABS (acrylonitrile-butadiene-styrene copolymer) 10 kg

[0101] Butyl acetate 25 kg

[0102] Dichloromethane 7kg

[0103] Polyacrylamide 15 kg

[0104] Polyethylene glycol 8 kg

[0105] Carboxyethyl cellulose 15 kg

[0106] Polyacrylate 20 kg.

[0107] Adhesive A preparation steps: sequentially add ABS, butyl acetate, dichloromethane into the reaction kettle with stirring device, stir at 50r / min for 3min, then raise the temperature to 70°C, then add polyacrylamide, Polyethylene glycol and carboxyethyl cellulose were stirred for 15 minutes, then vacuumed and degassed to obtain a composite glue; then polyacrylate was added to the reaction kettle, stirred and heated to 120°C, the composite glue was added, stirred for 5 minutes, and naturally cooled to obtain Adhesive A. It has been determined that the melt viscosity of the adhesive A prepared in this example is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com