Magnesium alloy wire doped with graphene and preparing method thereof

A graphene and magnesium alloy technology, applied in the field of alloy materials, can solve the problems of insufficient strength, hardness, and fire resistance, and can achieve excellent specific strength, improved stability, cutting performance and usability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Reclaimer:

[0056] Take materials according to the following percentages: the content of graphene is 0.15%, the content of Al is 8%, the content of Ti is 5%, the content of Cr is 4%, the content of Ni is 0.1%, the content of Ga is 4%, the content of Sm The content of Yb is 0.1%, the content of Yb is 4%, and the balance is magnesium.

[0057] mix:

[0058] Heat the alloy powder to 700-750°C until it melts, add graphene to it, and stir evenly.

[0059] Melting and casting:

[0060] Heat the mixture to 850-900°C (the heating rate is controlled at 10-20°C / min), keep it warm for 2 hours, carry out smelting, and then cast it into a rod of about Φ15mm.

[0061] Repeated drawing and annealing:

[0062] Cold-draw the bar to an alloy wire of about Φ10mm, then anneal for the first time at 600-800°C (the heating rate is controlled at 10-15°C / min), keep it warm for about 10 minutes, and then draw the alloy wire for the second time to The alloy wire of about Φ3mm is then anneal...

Embodiment 2-5

[0064] The difference between embodiment 2-5 and embodiment 1 is only that the doping amount of graphene is different, is respectively 0.2%, 0.6%, 1%, 4%, the percentage content of other metal elements except magnesium is the same, and magnesium is the remainder. quantity.

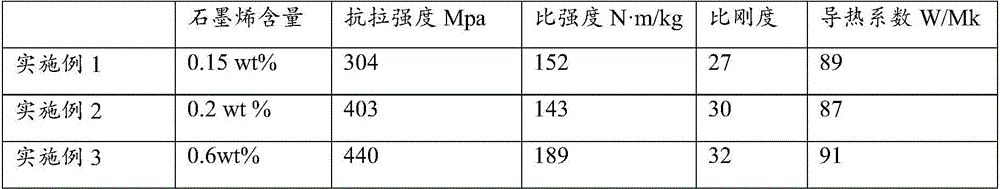

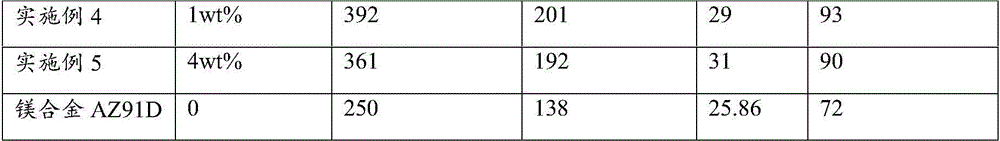

[0065] The properties of the magnesium alloy wires of Examples 1 to 5 were tested and compared with the magnesium alloy AZ91D, as shown in Table 1.

[0066] Table 1

[0067]

[0068]

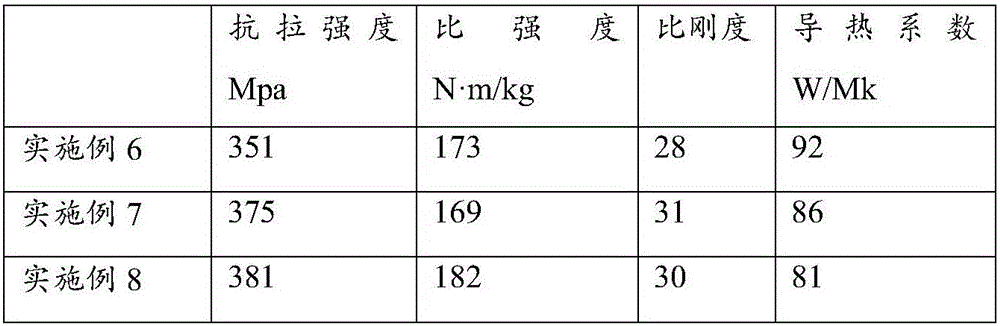

Embodiment 6

[0070] Reclaimer:

[0071] According to the following percentages: the content of graphene is 4%, the content of Al is 6%, the content of Ti is 7%, the content of Cr is 0.1%, the content of Ni is 4%, the content of Ga is 0.1%, the content of Sm The content of Yb is 4%, the content of Yb is 0.1%, and the balance is magnesium.

[0072] mix:

[0073] Heat the alloy powder to 750-800°C until it melts, add graphene to it, and stir evenly.

[0074] Melting and casting:

[0075] Heat the mixture to 900-1000°C (the heating rate is controlled at 15-20°C / min), keep it warm for 2 hours, melt it, and then cast it into a rod of about Φ15mm.

[0076] Repeated drawing and annealing:

[0077] Cold-draw the bar to an alloy wire of about Φ10mm, then anneal for the first time at 700-800°C (the heating rate is controlled at 10-15°C / min), keep it warm for about 1 hour, and then draw the alloy wire for the second time to The alloy wire of about Φ3mm is then annealed for the second time at 500-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com