Formic acid composite cleaning agent for condensers in thermal power plants

A compound cleaning agent and thermal power plant technology, applied in the field of chemical cleaning, can solve the problems of stainless steel intergranular corrosion, severe corrosion, equipment corrosion, etc., and achieve the effect of safe dosing, small corrosion, and rapid descaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Taking the preparation of formic acid composite cleaning agent 1000kg as an example, the raw materials used and their quality proportions are as follows:

[0027]

[0028]

[0029] Its preparation method is as follows: first add 1.5kg of ethylene glycol and 0.2kg of surfactant OP-10 to 700kg of deionized water, heat to 60°C, then add 0.6kg of 2-mercaptobenzothiazole and stir to make 2-mercaptobenzene Parathiazole was completely dissolved, then 0.3kg of 2-aminoethyl heptadecenyl imidazoline was added, and after stirring evenly, 249.4kg of deionized water, 40kg of formic acid, and 8kg of sulfamic acid were added in sequence, and stirred evenly, to prepare a formic acid composite cleaning agent.

Embodiment 2

[0031] Taking the preparation of formic acid composite cleaning agent 1000kg as an example, the raw materials used and their quality proportions are as follows:

[0032]

[0033] Its preparation method is identical with embodiment 1.

Embodiment 3

[0035] Taking the preparation of formic acid composite cleaning agent 1000kg as an example, the raw materials used and their quality proportions are as follows:

[0036]

[0037] Its preparation method is identical with embodiment 1.

[0038] In order to determine the best raw material proportioning of the present invention, inventor has carried out a large amount of laboratory research experiments, and various test conditions are as follows:

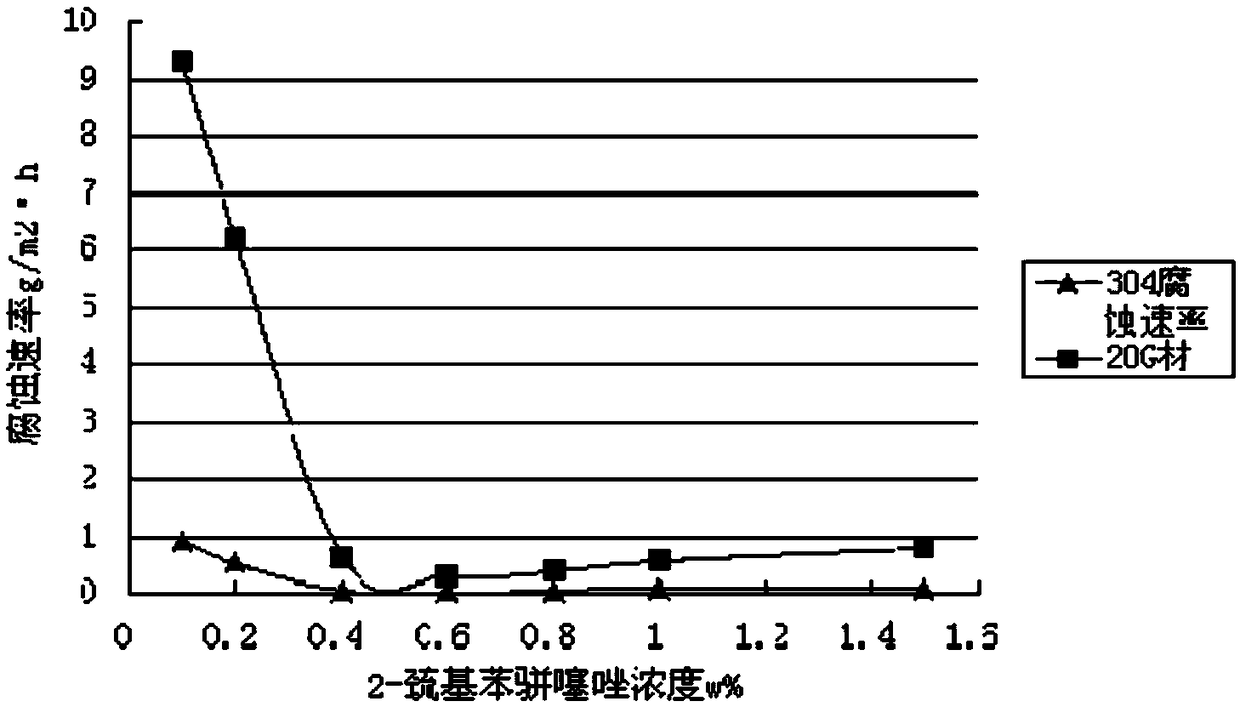

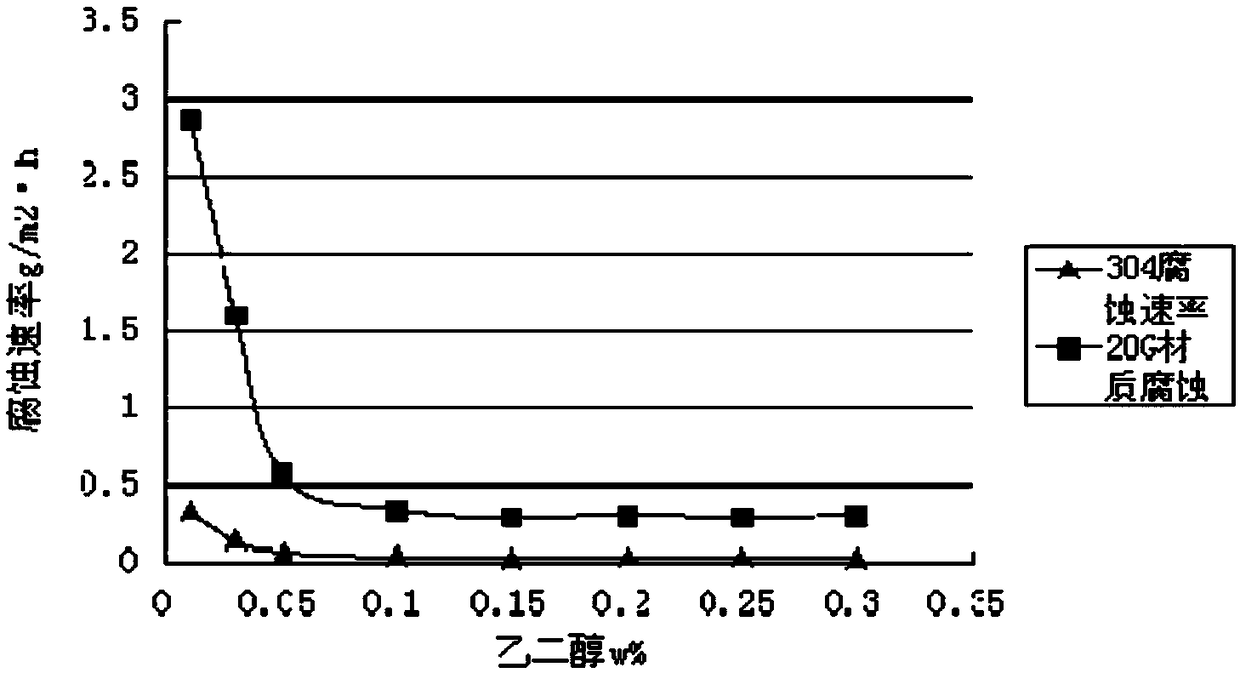

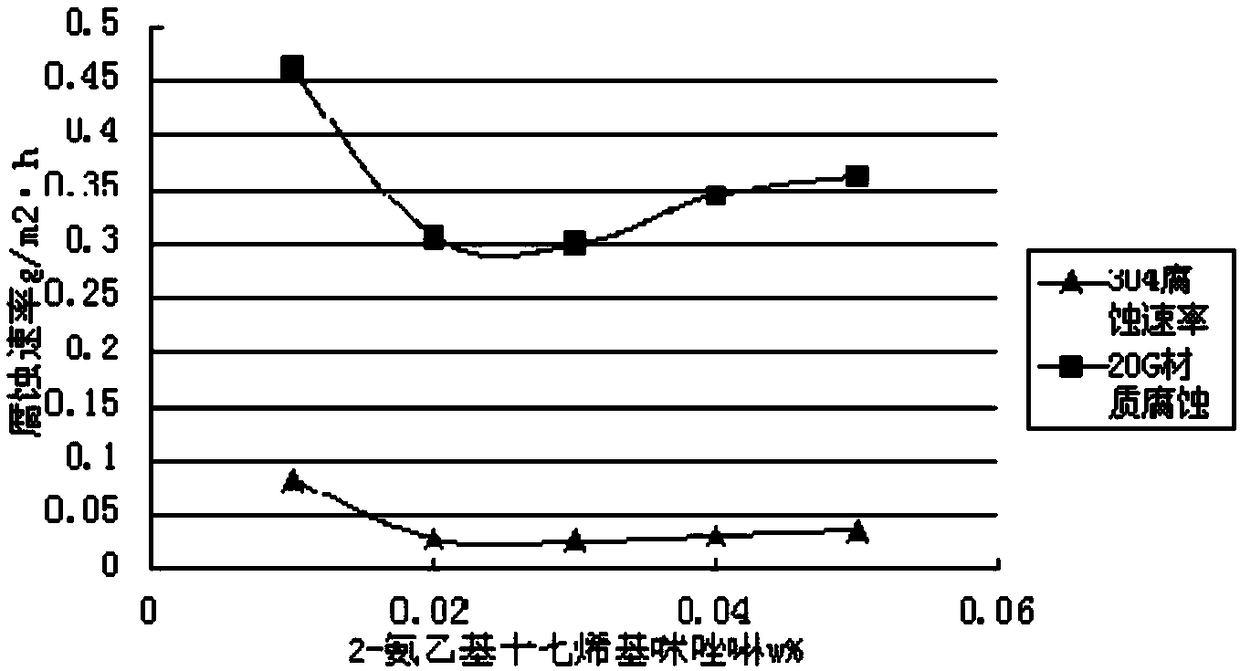

[0039] The main medium in the cleaning agent of the present invention is formic acid, and its component size only needs to be able to dissolve the scale, which is economical and can reduce the corrosion of equipment; a small amount of aminosulfonic acid is to promote the dissolution of a small amount of insoluble matter in the scale, The remaining components are additives, which can slow down corrosion. First, determine the content of formic acid and sulfamic acid through the analysis of scale composition and scale amount, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com