Coal slime drying system and drying technique thereof

A technology of drying system and drying process, which is applied in the direction of drying solid materials, dry cargo handling, and drying gas arrangement, etc., which can solve the problems of large equipment volume, large floor area, and complicated process, so as to achieve high dispersion efficiency and improve drying efficiency. Efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

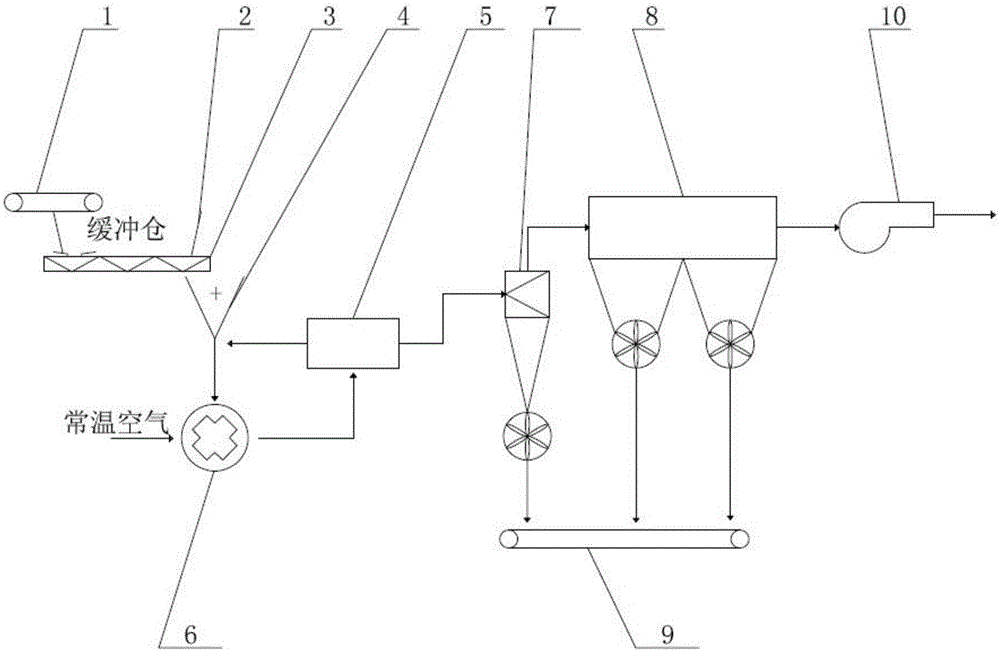

[0052] Such as figure 1 As shown, the coal slime drying system described in this embodiment includes a coal slime buffer bin 2, a screw feeder 3, a coal slime crusher 4, a material separator 5, a drying and dispersing machine 6, a cyclone separator 7, Bag filter 8 and induced draft fan 10, in figure 1 Among them, 1 represents wet coal slime (before drying), and 9 represents coal powder particles (coal powder particles formed after wet coal slime is dried).

[0053] Coal slime buffer bin 2 is used to receive and store wet coal slime 1, the outlet end of coal slime buffer bin 2 is connected to the inlet end of screw feeder 3, the outlet end of screw feeder 3 is connected to the inlet end of coal slime crusher 4 connection, wherein: the wet coal slime 1 in the coal slime buffer bin 2 is sent to the coal slime crusher 4 through the screw feeder 3, and in the coal slime crusher 4, the wet coal slime is pre-crushed to form coal slime particles. The size of the wet slime 1 enterin...

Embodiment 2

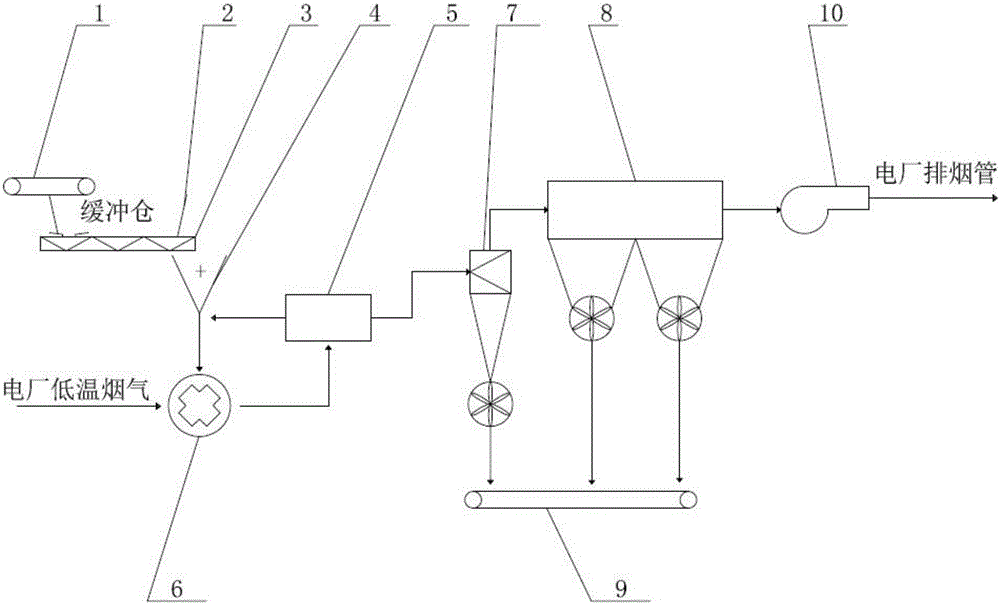

[0067] Such as figure 2 As shown, the embodiment of the present invention also provides a coal slime drying system, including a coal slime buffer bin 2, a screw feeder 3, a coal slime crusher 4, a material separator 5, a drying and breaking machine 6, a cyclone separation Device 7, bag filter 8 and induced draft fan 10, in figure 2 Among them, 1 represents the wet coal slime before drying, and 9 represents the dried coal slime (coal powder).

[0068] In this embodiment, what the air inlet of the drying and dispersing machine 6 introduces is the low-temperature flue gas of the power plant, and the drying and dispersing machine 6 uses the low-temperature flue gas to dry and disperse the wet coal slime, which improves the efficiency of drying and dispersing. scattered efficiency.

[0069] The connection relationship and function description of each component in the coal slime drying system provided by the embodiment of the present invention are the same as those in the first ...

Embodiment 3

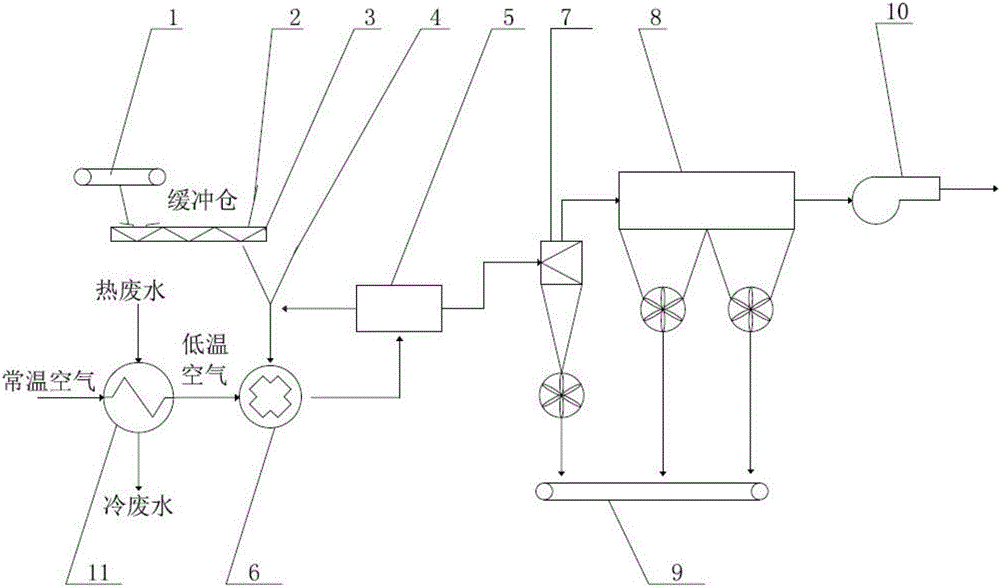

[0071] Such as image 3 As shown, the embodiment of the present invention also provides a coal slime drying system, including a coal slime buffer bin 2, a screw feeder 3, a coal slime crusher 4, a material separator 5, a drying and breaking machine 6, a cyclone separation Device 7, bag filter 8 and induced draft fan 10, in image 3 Among them, 1 represents the wet coal slime before drying, and 9 represents the dried coal slime (coal powder).

[0072] The coal slime drying system provided by the embodiment of the present invention also includes a plate heat exchanger 11, in which the normal temperature gas and the hot waste water / hot steam discharged from the power plant are input into the plate heat exchanger 11, and the hot waste water / hot steam is exchanged with the normal temperature air , the cold waste water produced is directly discharged, and the hot air (also called "low temperature air") produced enters the drying and breaking machine 6 through the air inlet of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com