Ceramic capacitor of crystal boundary layer and manufacturing process of capacitor

A technology of ceramic capacitors and manufacturing processes, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., and can solve the problems of small size of single-layer chip ceramic capacitors, lower product qualification rate and reliability, gold layer adhesion and performance decline and other problems, to achieve the effect of avoiding the decrease of adhesion, high reliability and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

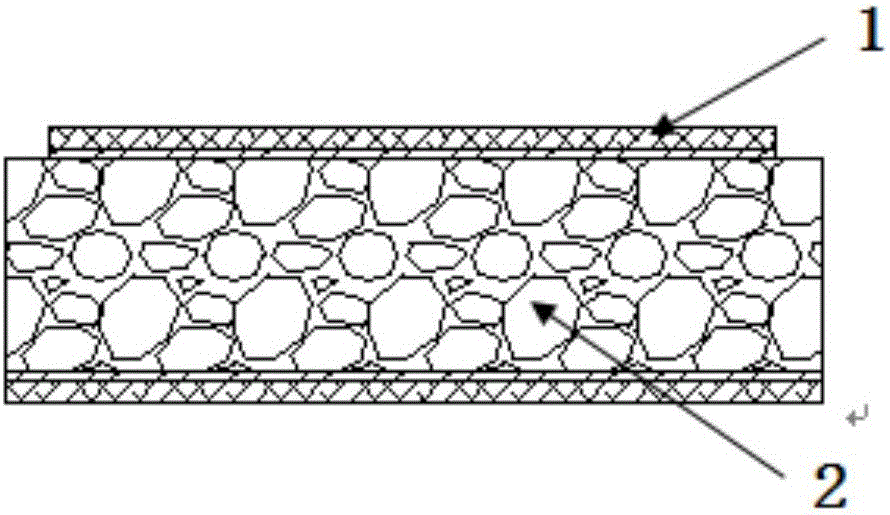

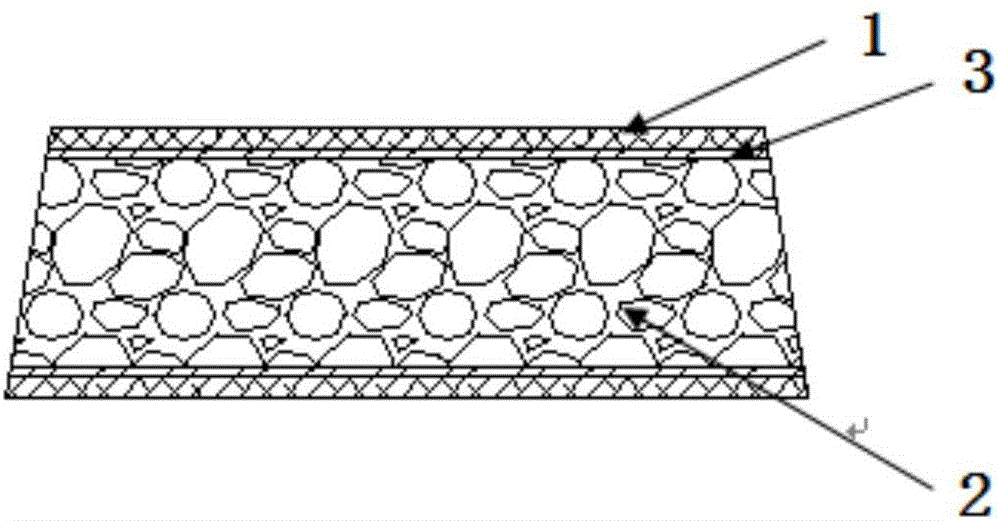

[0030] Such as figure 2 As shown, a grain boundary layer ceramic capacitor includes a gold electrode 1, a grain boundary layer ceramic 2 and a Tiw transition layer 3, and the two sides of the grain boundary layer ceramic 2 are respectively provided with a Tiw transition layer 3, and the Tiw transition layer 3 A gold electrode 1 is provided on both sides, and the gold electrode 1, the Tiw transition layer 3 and the grain boundary layer ceramic 2 have the same length. The upper and lower surfaces of the grain boundary layer capacitor are parallel, the edges are sloped, and the cross section is trapezoidal.

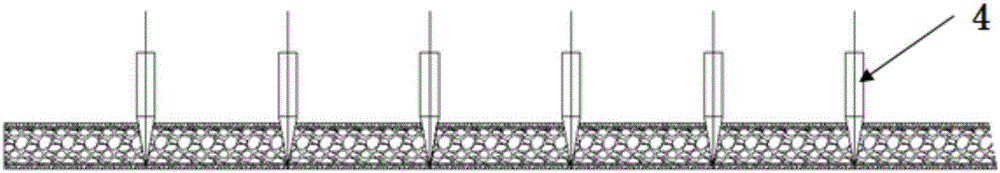

[0031] Single-layer chip ceramic capacitors are prepared by using a special cutting process, which greatly improves the pass rate and reliability of the product. The steps are as follows:

[0032] Step 1, check the appearance and size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com