Manufacturing method of thin film chip and thin film chip thereof

A thin-film chip and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high AlGaN layer stress, precise control of grinding, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

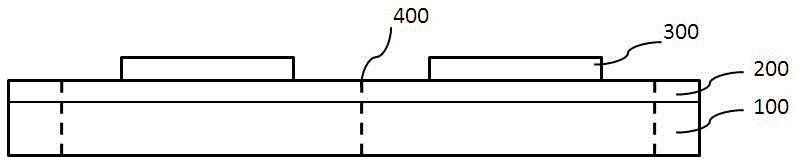

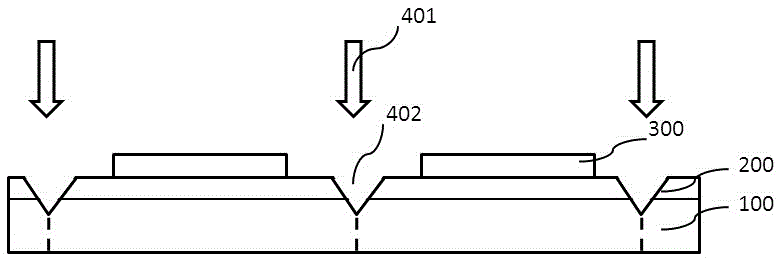

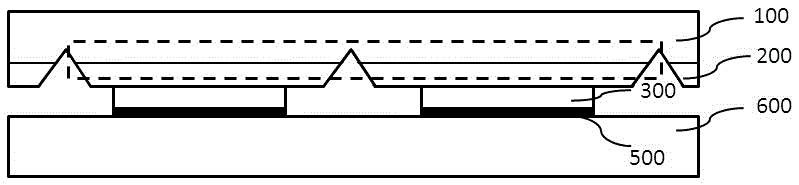

[0029] like figure 1 As shown, a light-emitting epitaxial wafer is provided. First, sapphire is used as a growth substrate 100, and an N-type III-V thin film, a light-emitting active layer, and a P-type III-V thin film are grown on the growth substrate 100, as Light emitting epitaxial stack 200 . The Group III-V thin film can be composed of boron, aluminum, gallium, indium of group III and nitrogen, phosphorus and arsenic of group V. The luminescent wavelength of the luminescent active layer is between 200-1150nm, preferably in the ultraviolet band, such as UV-C band (200-280nm), UV-B band (280-315nm) and UV-A band (315-380nm). Next, several chip structure layers 300 are fabricated on the light-emitting epitaxial stack, and dicing lines 400 are defined on the surface of the light-emitting epitaxial stack between adjacent chip structure layers, wherein the chip structure layer 300 may further include a contact layer and a mirror reflector. layer (Mirror).

[0030] like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com