Method for preparing hard alloy in vacuum extrusion mode

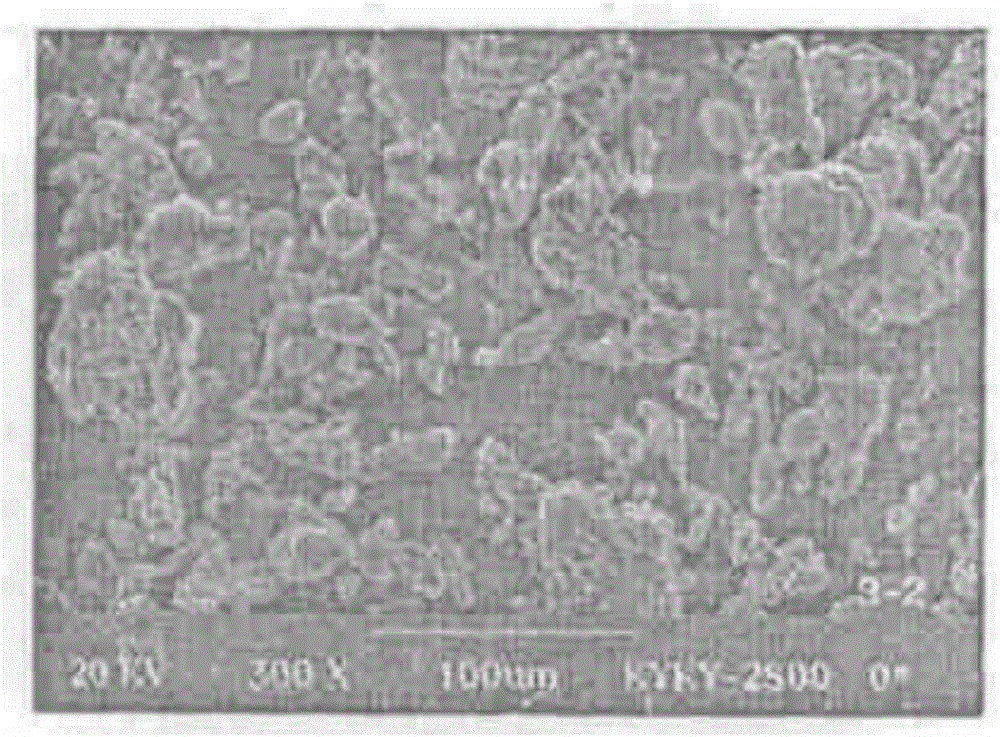

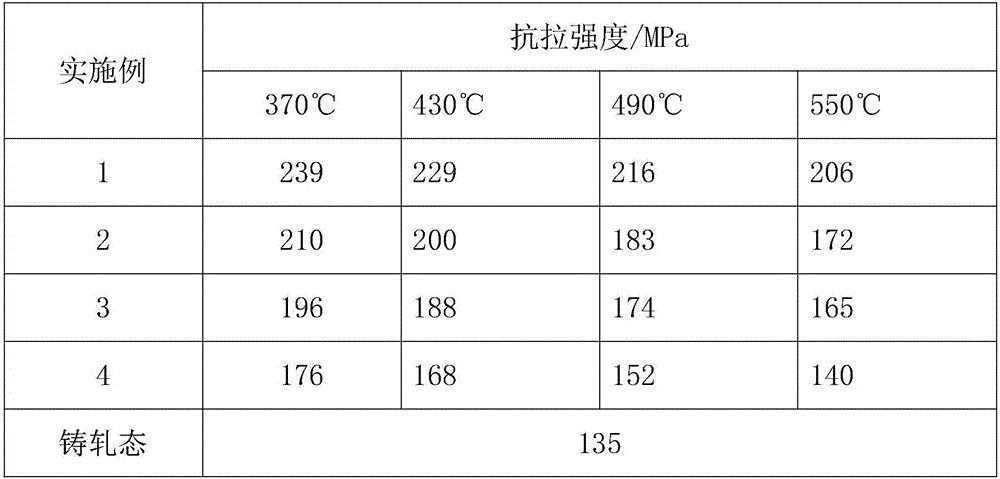

A cemented carbide and vacuum extrusion technology, which is applied in the field of preparing cemented carbide by vacuum extrusion, can solve the problems of insufficient tensile strength structure, poor microscopic surface, insufficient compactness, etc., and achieves compact microstructure and improved Wear resistance and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

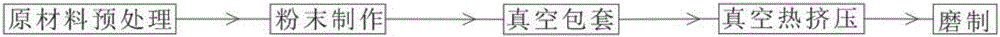

[0021] A method for preparing cemented carbide by vacuum extrusion, comprising the following steps:

[0022] S1. Pretreatment of raw materials, cleaning the raw materials, removing the adhering pollutants on the surface, and then using pickling to remove the oxides on the surface, and drying;

[0023] S2, powder preparation, put the dried raw materials into the melting furnace to melt, the liquefied metal droplets are injected into the spray device through the leak nozzle, and are blown out and atomized by the high-pressure gas, and the atomized metal liquid is directly sprayed into the high-pressure water flow, and the high-pressure The water flow is collected and filtered and entered into a high-speed rotating dryer for dehydration treatment, and various powders are obtained after drying and sieving;

[0024] S3, vacuum wrapping, the powder obtained in S2 is uniformly mixed, initially packed and vibrated into a special metal wrapping, and after vacuum degassing, the metal wr...

Embodiment 2

[0029] A method for preparing cemented carbide by vacuum extrusion, comprising the following steps:

[0030] S1. Pretreatment of raw materials, cleaning the raw materials, removing the adhering pollutants on the surface, and then using pickling to remove the oxides on the surface, and drying;

[0031] S2, powder preparation, put the dried raw materials into the melting furnace to melt, the liquefied metal droplets are injected into the spray device through the leak nozzle, and are blown out and atomized by the high-pressure gas, and the atomized metal liquid is directly sprayed into the high-pressure water flow, and the high-pressure The water flow is collected and filtered and entered into a high-speed rotating dryer for dehydration treatment, and various powders are obtained after drying and sieving;

[0032] S3, vacuum wrapping, the powder obtained in S2 is uniformly mixed, initially packed and vibrated into a special metal wrapping, and after vacuum degassing, the metal wr...

Embodiment 3

[0037] A method for preparing cemented carbide by vacuum extrusion, comprising the following steps:

[0038] S1. Pretreatment of raw materials, cleaning the raw materials, removing the adhering pollutants on the surface, and then using pickling to remove the oxides on the surface, and drying;

[0039] S2, powder preparation, put the dried raw materials into the melting furnace to melt, the liquefied metal droplets are injected into the spray device through the leak nozzle, and are blown out and atomized by the high-pressure gas, and the atomized metal liquid is directly sprayed into the high-pressure water flow, and the high-pressure The water flow is collected and filtered and entered into a high-speed rotating dryer for dehydration treatment, and various powders are obtained after drying and sieving;

[0040] S3, vacuum wrapping, the powder obtained in S2 is uniformly mixed, initially packed and vibrated into a special metal wrapping, and after vacuum degassing, the metal wr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com