Lightweight flexible high thermal conductivity nano-carbon composite film and preparation method thereof

A nano-carbon and composite film technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor adhesion between resin and graphene film, poor flexibility of graphene film, easy peeling, etc. Easy to peel off, broad application prospects, and the effect of improving bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The following embodiments also provide a method for preparing a lightweight, flexible and highly thermally conductive nano-carbon composite film, comprising the following steps:

[0051]The first step is to prepare a flexible bonding layer. In order to control the thermal conductivity and flexibility of the carbon nanocomposite film, the flexible bonding layer can choose carbon nanotube film / resin prepreg or carbon nanotube / resin slurry slurry. For nano-carbon composite films with high thermal conductivity and flexibility, choose carbon nanotube film / resin prepreg; otherwise, choose carbon nanotube / resin slurry as a flexible bonding layer.

[0052] The preparation of carbon nanotube film / resin prepreg comprises the following steps:

[0053] (a) Dissolving the resin in a solvent to prepare a resin solution with a certain concentration, the mass content of the resin in the solution is controlled at 10% to 30%, and the resin is: epoxy resin, double horse resin, phenolic re...

Embodiment 1

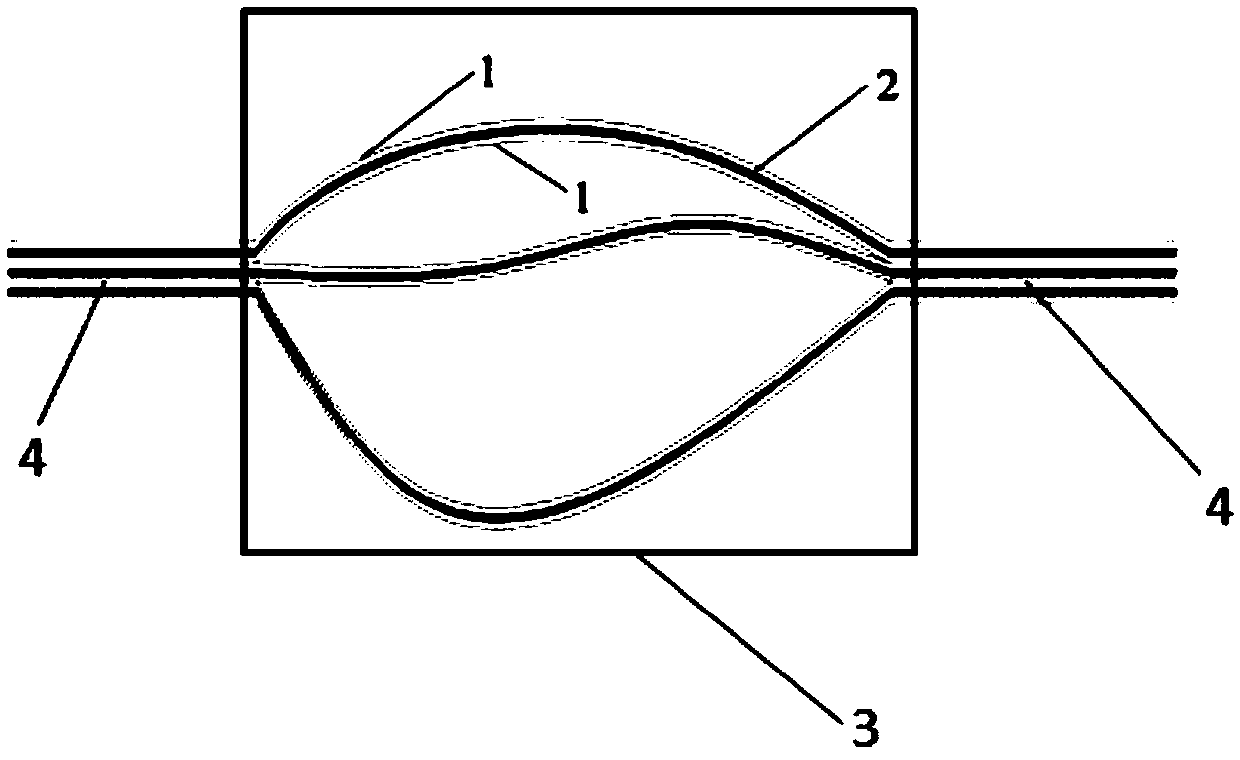

[0064] This embodiment provides a light, flexible, high thermal conductivity nano-carbon composite film and a preparation method thereof. The nano-composite film is a multilayer structure comprising a carbon nanotube film / resin prepreg and a graphene film layer, which has a fixed A typical structure of two parts, the end and the flexible segment. Described preparation method, concrete steps are as follows:

[0065] In the first step, a flexible adhesive layer is prepared, and a carbon nanotube film with a length of 1000 mm, a width of 200 mm, and a thickness of 10 μm is cut with a scalpel. The carbon nanotube film is prepared by chemical vapor deposition and floating catalytic method. The carbon nanotube / resin prepreg was prepared by resin solution impregnation method, AG80 resin, DDS curing agent and BF3·MEA were mixed uniformly at a mass ratio of 100:30:1 to form a resin system, and then the resin system was mixed with acetone at 30 : The mass ratio of 70 is mixed evenly to...

Embodiment 2

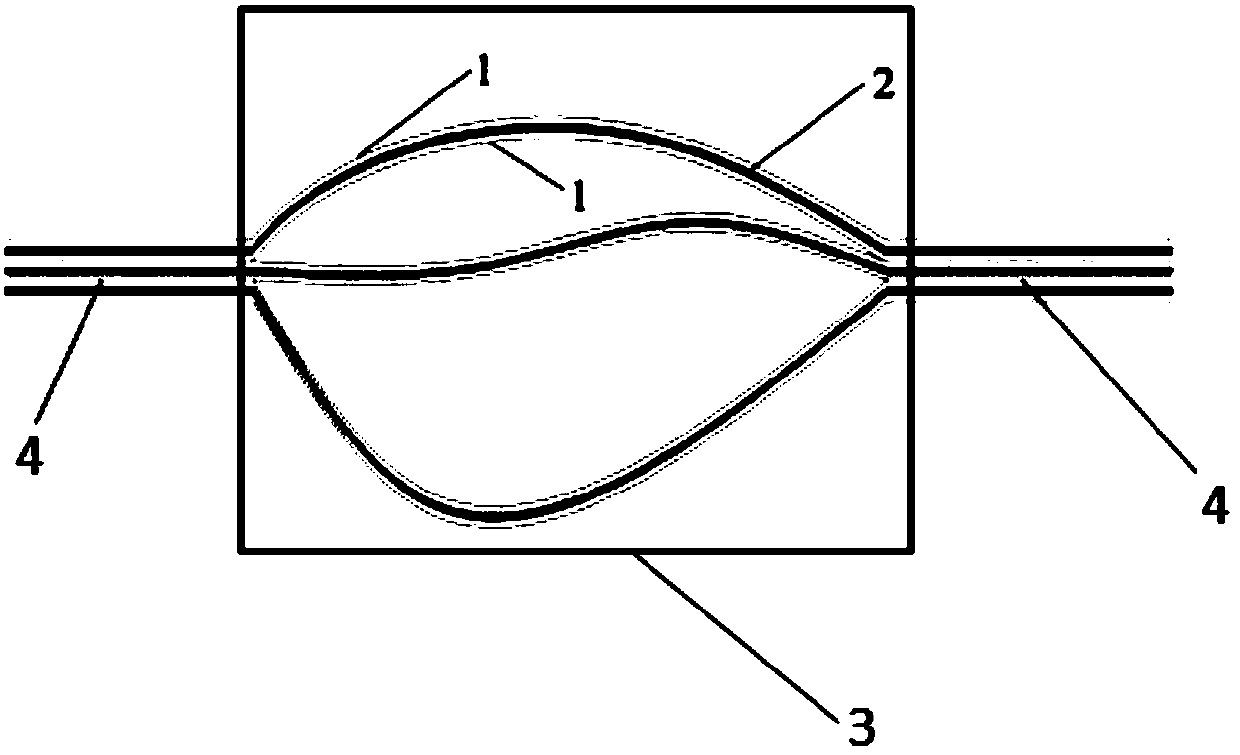

[0071] This embodiment provides a light, flexible, high thermal conductivity nano-carbon composite film and a preparation method thereof. The nano-composite film is a multilayer structure comprising carbon nanotubes / resin slurry and a graphene film layer, which has a fixed section and Typical structure of the two parts of the flexible segment. Described preparation method, concrete steps are as follows:

[0072] The first step is to prepare a flexible adhesive layer, and mix E51 resin and 2-ethyl-4 methylimidazole at a mass ratio of 100:7 to form a resin system. Select multi-walled carbon nanotubes with a diameter of 20 μm, pour 1 g of carbon nanotubes into 99 g of resin system and stir for 30 min. Then use a three-roll mill to disperse, and disperse the carbon nanotube / resin mixture twice to obtain a uniform carbon nanotube dispersion. Then 100 g of acetone solution was poured into the carbon nanotube dispersion and stirred for 30 minutes to obtain a carbon nanotube / resin s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com