Method for preparing ice-coating resistant zinc oxide coating on copper surface

A zinc oxide, anti-icing technology, applied in coating, metal material coating process, liquid chemical plating, etc., can solve the problem of reducing aircraft maneuverability, stability and other safety performance, threatening aircraft flight safety, and aerodynamic performance Variation and other problems, to achieve the effect of low requirements for reaction equipment, no environmental pollution, and increased contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

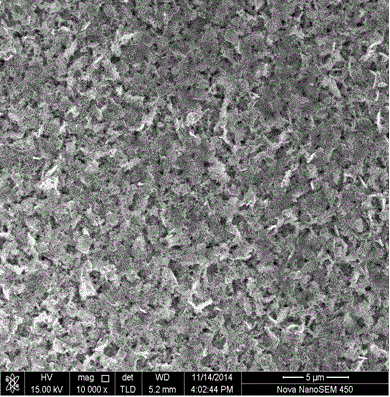

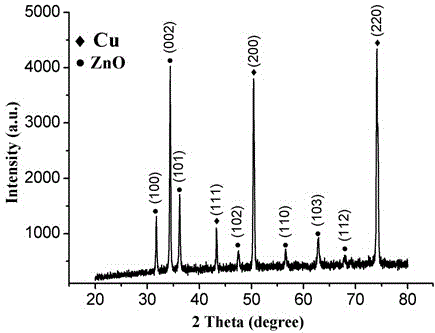

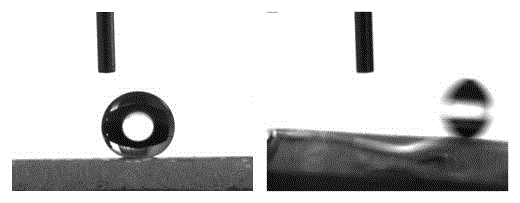

[0027] Specific embodiment one: the Zn(Ac) of preparation 0.15mol / L 2 Ethanol solution 0.15mol / L NaOH ethanol solution, stirred at a constant temperature of 80°C for 2h; added dopamine hydrochloride solution with a pH value of 8.5 to the solution obtained above, and stirred at a constant temperature of 80°C for 2h; Dry to obtain the seed layer; prepare ZnCl with a concentration of 0.05mol / L 2 solution, adding NH 3 . h 2 O to adjust its pH value to 10; put the copper sheet with the seed layer into the reaction kettle, pour the prepared ZnCl 2 solution, put the reaction kettle in an oven at 95°C for 4 h; take out the reaction kettle to cool down, take out the sample after cooling, dry it, put it in a horse-boiling furnace, the maximum temperature is 200°C, and the holding time is 4 h; prepare 1:1000 of twelve The ethanol solution of mercaptan was used to soak the sample for 20 minutes; the sample after soaking was taken out and measured the static contact angle and rolling a...

specific Embodiment approach 2

[0028] Specific embodiment two: the Zn(Ac) of preparation 0.15mol / L 2 Ethanol solution 0.15mol / L NaOH ethanol solution, stirred at a constant temperature of 80°C for 2h; added dopamine hydrochloride solution with a pH value of 8.5 to the solution obtained above, and stirred at a constant temperature of 80°C for 2h; Dry to obtain the seed layer; prepare ZnCl with a concentration of 0.05mol / L 2 solution, adding NH 3 . h 2 O to adjust its pH value to 10; put the copper sheet with the seed layer into the reaction kettle, pour the prepared ZnCl 2 solution, put the reaction kettle in an oven at 95°C for 6 h; take out the reaction kettle to cool down, take out the samples after cooling, dry them, put them in a horse-boiling furnace, the maximum temperature is 200°C, and the holding time is 4 h; prepare 1:1000 twelve The ethanol solution of mercaptan was used to soak the sample for 20 minutes; the sample after soaking was taken out and measured the static contact angle and rolling...

specific Embodiment approach 3

[0029] Specific embodiment three: the Zn(Ac) of preparation 0.15mol / L 2 Ethanol solution 0.15mol / L NaOH ethanol solution, stirred at a constant temperature of 80°C for 2h; added dopamine hydrochloride solution with a pH value of 8.5 to the solution obtained above, and stirred at a constant temperature of 80°C for 2h; Dry to obtain the seed layer; prepare ZnCl with a concentration of 0.05mol / L 2 solution, adding NH 3 . h 2 O to adjust its pH value to 12; put the copper sheet with the seed layer into the reaction kettle, pour the prepared ZnCl 2 solution, put the reaction kettle into an oven at 95°C for 6 h; take out the reaction kettle to cool down, take out the sample after cooling and dry it, put it in a horse-boiling furnace, the maximum temperature is 200°C, and the holding time is 4 h; prepare 1:1000 twelve The ethanol solution of mercaptan was used to soak the sample for 20 minutes; the sample after soaking was taken out and measured the static contact angle and rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com