Thermally conductive and insulating corrosion-resisting modified plastic and manufacturing method thereof

A heat-conducting, insulating, and corrosion-resistant technology, applied in the field of heat-conducting, insulating, and corrosion-resistant modified plastics and its production, can solve the problems of devices not working properly, corrosion resistance of metal materials, poor molding processability, etc., and achieve good heat-conducting and insulating effects , Good thermal insulation effect, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

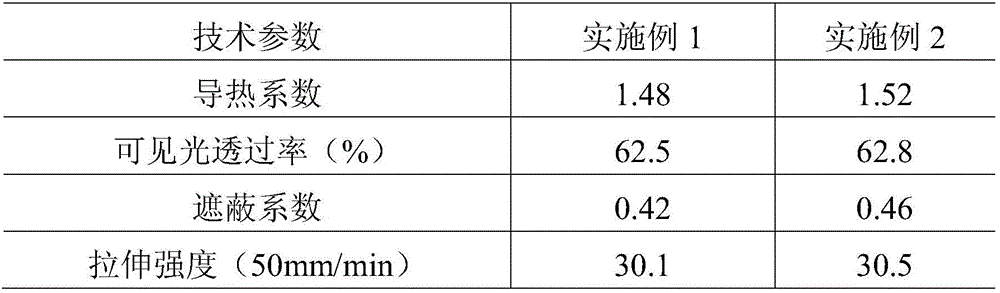

Examples

Embodiment 1

[0014] A heat-conducting, insulating, and corrosion-resistant modified plastic, consisting of the following components in parts by weight:

[0015] Chlorinated polyethylene 50, polytetrafluoroethylene 10, polypropylene 15, maleic anhydride grafted polyethylene 4, zinc stearate 2, liquid paraffin 0.5, silane coupling agent 4, nano silicon dioxide 3, thermally conductive alumina powder 9, nano zinc oxide 2, antioxidant PS8020.5.

[0016] The manufacturing method of the above-mentioned heat-conducting, insulating and corrosion-resistant modified plastic comprises the following steps:

[0017] Step 1: Put the heat-conducting alumina powder and nano-zinc oxide in a 35KHz ultrasonic cleaner, and use absolute ethanol for 20 minutes of ultrasonication; after the ultrasonic wave is completed, wash with absolute ethanol for 3 times, dry at 60°C to constant weight, and set aside ;

[0018] Step 2: According to the formula, chlorinated polyethylene, polytetrafluoroethylene, polypropylen...

Embodiment 2

[0020] A heat-conducting, insulating, and corrosion-resistant modified plastic, consisting of the following components in parts by weight:

[0021] Chlorinated polyethylene 37, polytetrafluoroethylene 15, polypropylene 20, maleic anhydride grafted polyethylene 5, zinc stearate 2.5, liquid paraffin 0.5, silane coupling agent 5, nano silicon dioxide 3, thermally conductive alumina powder 10, nano zinc oxide 1.5, antioxidant PS8020.5.

[0022] The manufacturing method of the above-mentioned heat-conducting, insulating and corrosion-resistant modified plastic comprises the following steps:

[0023] Step 1: Put the thermally conductive alumina powder and nano-zinc oxide in a 30KHz ultrasonic cleaner, and use absolute ethanol for 30 minutes of ultrasonication; after the ultrasonic wave is completed, wash with absolute ethanol for 3 times, dry at 60°C to constant weight, and set aside ;

[0024] Step 2: According to the formula, chlorinated polyethylene, polytetrafluoroethylene, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com