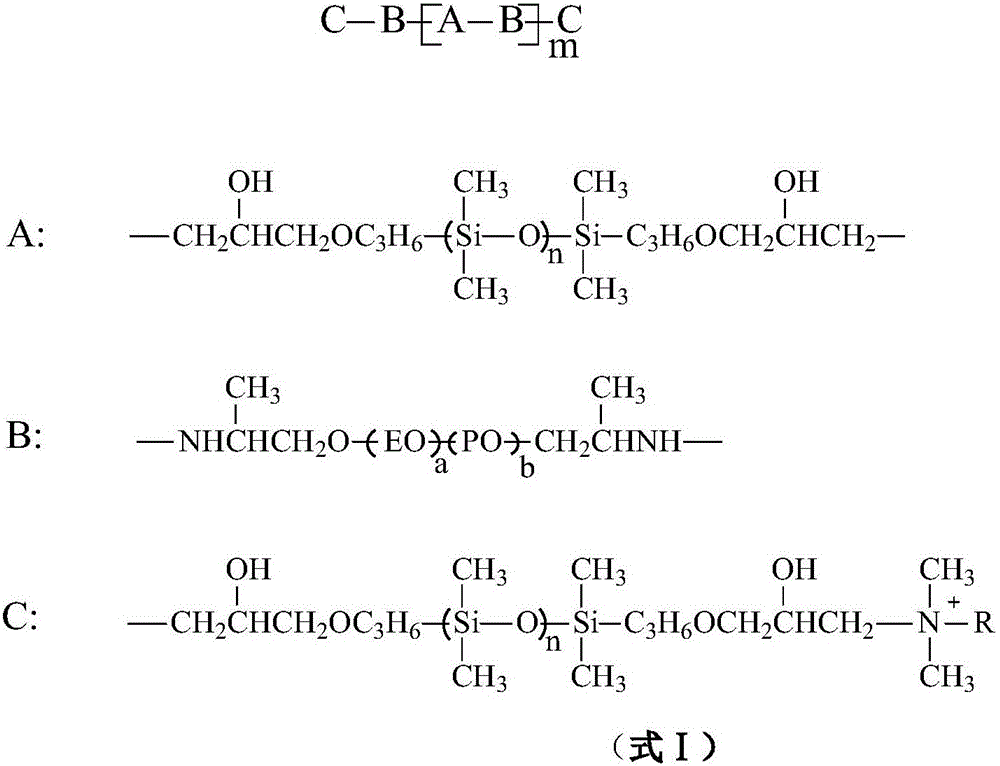

Quaternary ammonium modified block polyether/amino silicone oil and preparation method thereof

A technology of quaternization modification and block polyether, which is applied in the direction of improved handle fiber, textile and papermaking, fiber treatment, etc., can solve the problem of limited block polyether amino silicone oil hand feel, etc., to improve hydrophilicity and Antistatic, strong affinity, high retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

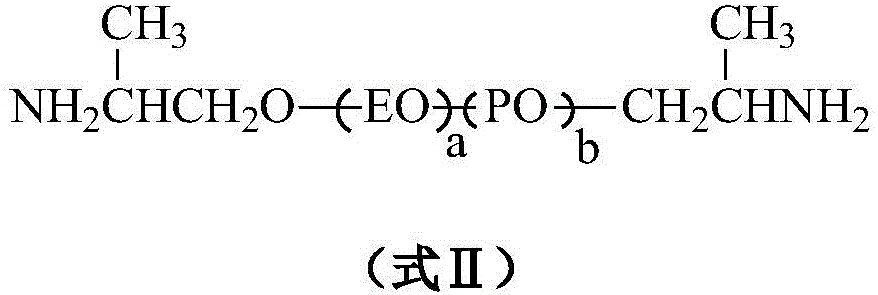

Method used

Image

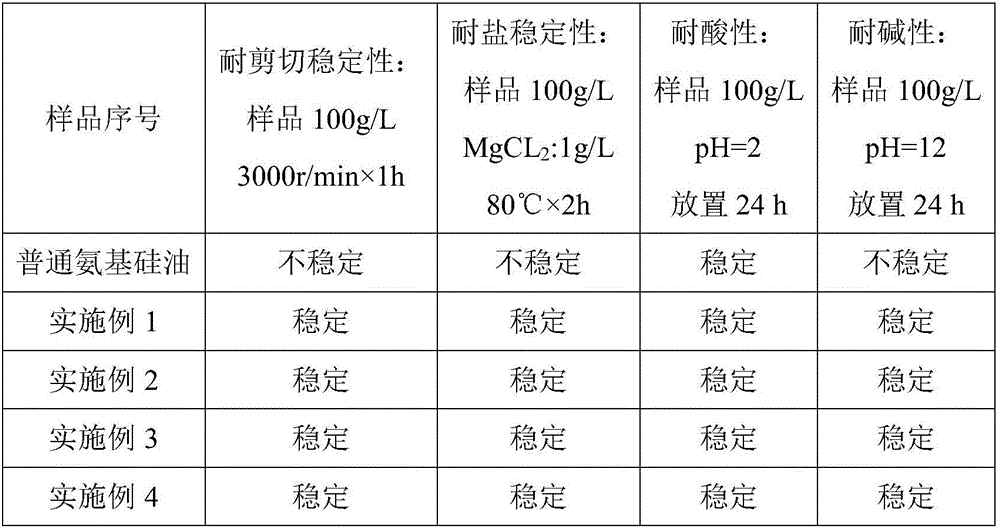

Examples

Embodiment 1

[0032] Mix 20g of epoxy double head, 490g of organosiloxane ring body (DMC) and 35g of N,N-dimethylacetamide, add 0.1g (CH 3 ) 4 NOH (added in the form of alkali glue), heated up to 100°C, equilibrated for 8h; then heated up to about 140°C to decompose the catalyst for 2h, and distilled off the solvent and low boilers under reduced pressure to obtain a colorless or light yellow terminal epoxy Silicone oil; Mix the epoxy-terminated silicone oil prepared in the previous step, 44.5g polyetheramine (molecular weight: 900) and 370g isopropanol, and react at 75°C for 15h to obtain block polyetheramino silicone oil; mix 3.5g Octadecyl dimethyl tertiary amine and 0.68 g of acetic acid were added to the reaction system, and reacted at 80°C for 6 hours to obtain the final product.

Embodiment 2

[0034] Mix 30g of epoxy double head, 915g of organosiloxane ring body (DMC) and 60g of N,N-dimethylacetamide, add 0.2g (CH 3 ) 4 NOH (added in the form of alkali glue), heated up to 100°C, equilibrated for 8h; then heated up to about 140°C to decompose the catalyst for 2h, and distilled off the solvent and low boilers under reduced pressure to obtain a colorless or light yellow terminal epoxy Silicone oil; Mix the epoxy-terminated silicone oil prepared in the previous step, 67g polyetheramine (molecular weight: 900) and 675g isopropanol evenly, and react at 75°C for 15h to obtain block polyetheramino silicone oil; mix 3.75g ten Add dialkyldimethyl tertiary amine and 1 g of acetic acid into the reaction system, and react at 80°C for 6 hours to obtain the final product.

Embodiment 3

[0036] Mix 20g of epoxy double head, 735g of organosiloxane ring body (DMC) and 50g of N,N-dimethylacetamide, add 0.15g (CH 3 ) 4 NOH (added in the form of alkali glue), heated up to 100°C, equilibrated for 8 hours; then heated up to about 140°C to decompose the catalyst for 2 hours, and distilled off the solvent and low boilers under reduced pressure to obtain a colorless or light yellow terminal epoxy Silicone oil: mix the epoxy-terminated silicone oil prepared in the previous step, 99.5g polyetheramine (molecular weight: 2000), 700g isopropanol and 350g ethylene glycol monobutyl ether, and react at 75°C for 15h to obtain a block poly Ether amino silicone oil; add 3.5g of octadecyldimethyl tertiary amine and 0.68g of acetic acid into the reaction system, and react at 80°C for 6h to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com