LED upside-down mounting structure

A LED chip, flip chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of large device size, low light output, and refraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

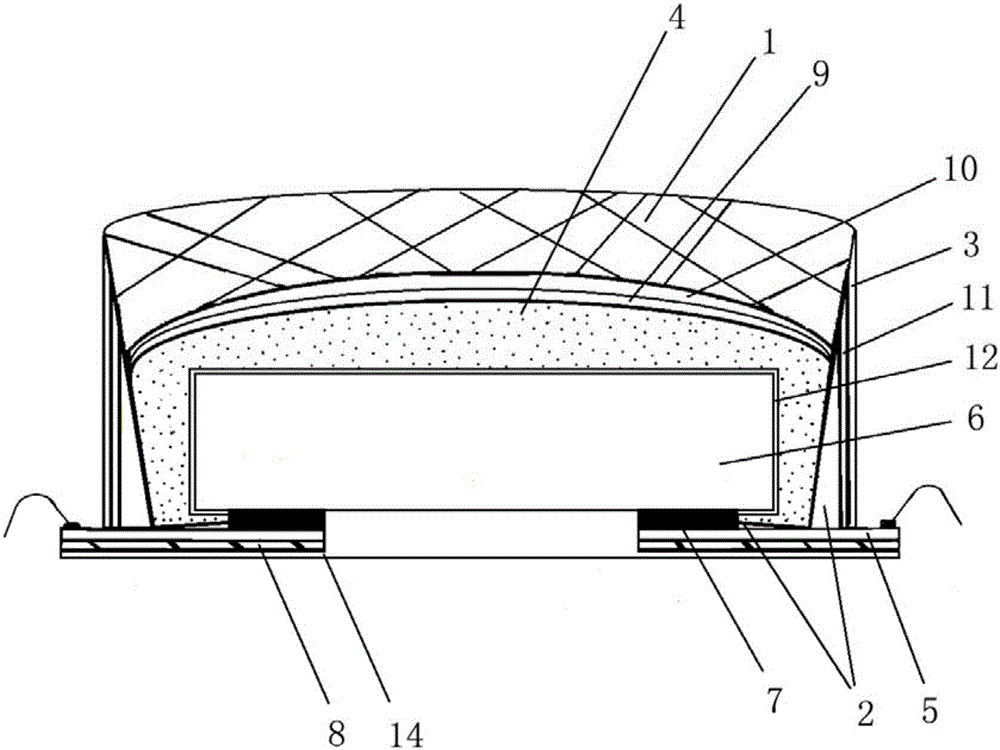

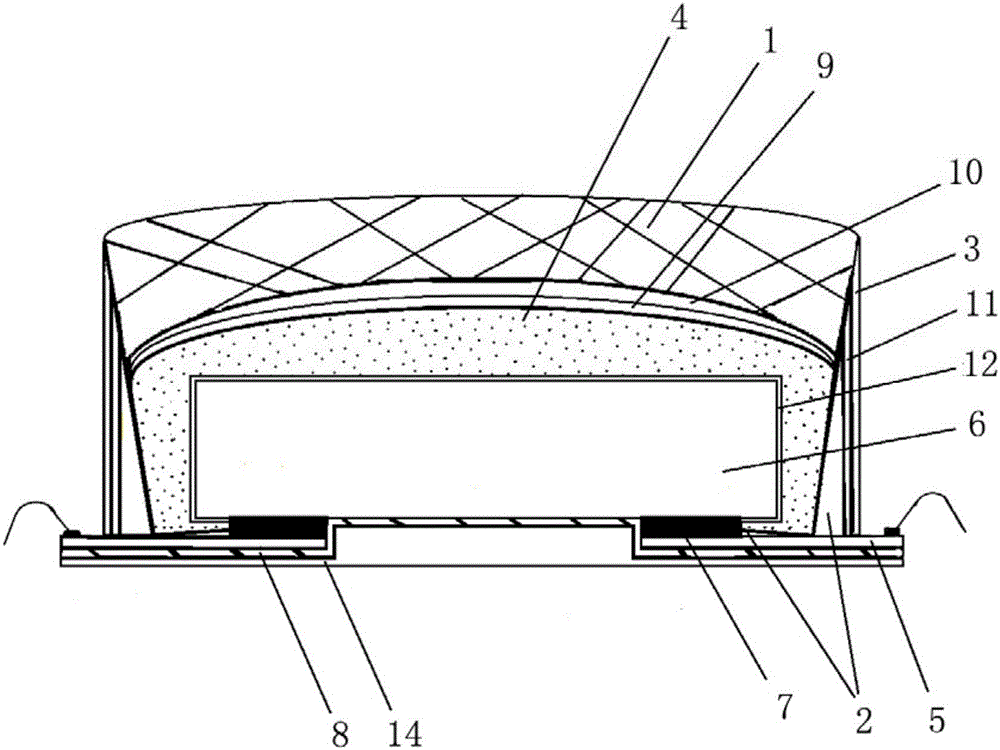

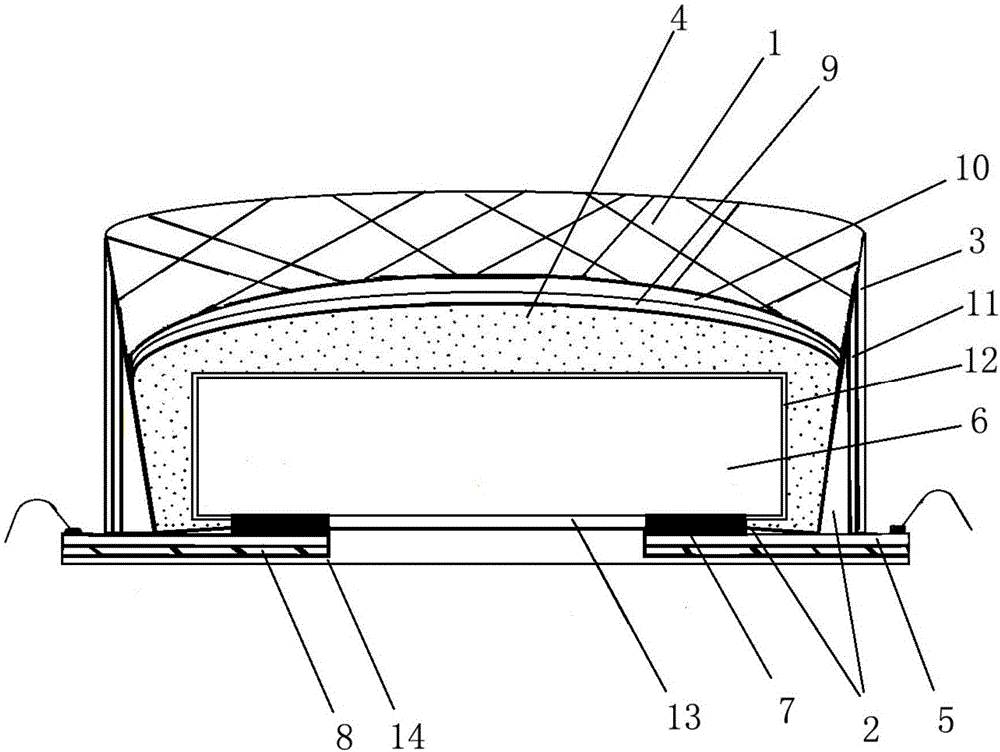

[0045] Such as figure 1 As shown, the present invention discloses an LED flip-chip structure, which mainly includes an LED chip 6, an insulating reflective cup 2, a fluorescent glue 4, a packaging glue layer 1, a conductive film 5, a welding pad 7, and a lens 9, which are used to improve the light extraction rate. An anti-reflection film 10 for reducing reflection effect, a silicon rubber layer 12 , and a sapphire substrate 14 . The conductive films 5 and the pads 7 are separated and insulated from each other. The insulating reflective cup 2 is arranged on the conductive film 5 and fixedly connected with the conductive film 5 for reflecting the light emitted by the LED chip 6 and fixing the packaging form of the LED. The bottom of the conductive film 5 is also provided with a ceramic film 8 for heat dissipation, and the ceramic film 8 of the sapphire substrate protrudes upwards between the two conductive films 5 to form a boss for isolating the conductive film 5, increasing ...

Embodiment 2

[0066] Such as figure 1 As shown, an LED flip-chip structure includes: LED chip 6, lens 9 doped or coated with fluorescent powder, fluorescent glue 4, insulating reflective cup 2, metal reflective cup 11, anti-reflection film 10, packaging adhesive layer 1. Transparent silicone rubber layer 12, welding pad 7, high temperature resistant conductive film 5, light absorbing layer 3, ceramic film 8 of sapphire substrate, thermal conductive adhesive layer 13. The LED chip 6 adopting the flip-chip structure is encapsulated in the fluorescent glue 4, and the surface of the LED chip is coated with a transparent silicone layer 12 with a high refractive index. The high-temperature conductive film 5 is electrically connected, and the upper surface of the fluorescent glue 4 is equipped with a lens 9 that is internally mixed or coated with phosphor powder. The upper surface of the lens 9 is also provided with an anti-reflection film 10 that enhances light transmission. 10 The upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com