Cotton seed coating agent for promoting roots and seedlings and preparation method thereof

A cotton seed and film-forming agent technology, applied in botany equipment and methods, biocides, disinfectants, etc., can solve problems affecting cotton yield and quality improvement, weak and late hair growth, underdeveloped cotton seedling root system, etc., to achieve Effects of promoting photosynthesis, promoting cold resistance, and increasing photosynthetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the seed coating agent of the present embodiment is as follows:

[0020] Preparation raw materials: Potassium permanganate 1g, benzylamine 2g, vitamin B 6 1g, manganese sulfate 2g, zinc sulfate 2g, ammonium molybdate 2g, chitosan oligosaccharide 2g, potassium dihydrogen phosphate 1g, amytal 0.5, starch 9g.

[0021] Add 9g of starch into 100ml of water, stir evenly, heat and stir evenly to form a paste to obtain film-forming milk; add the remaining raw materials to the film-forming milk, and stir rapidly for 30 minutes to obtain a seed coating agent.

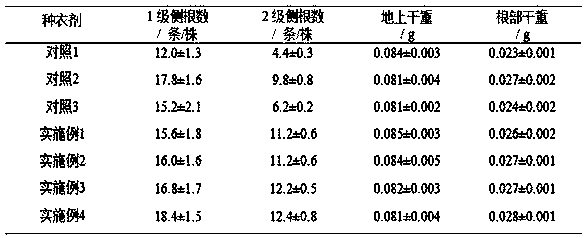

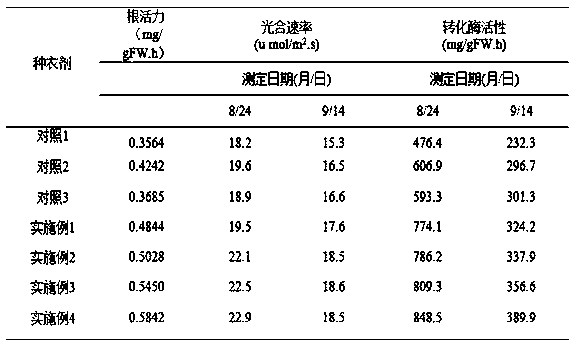

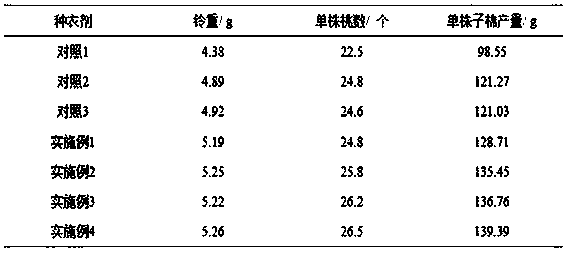

[0022] Use the seed coating agent prepared in this example to add 100 ml of the seed coating agent to 1 kg of photonic cotton seeds and mix evenly to treat the cotton seeds. After the treatment is dried, they are sown, and then the indicators in the cotton growth process are measured. Among them, the effects of seed coating agents on the number of lateral roots and seedling height of cotton seedl...

Embodiment 2

[0024] The preparation method of the seed coating agent of the present embodiment is as follows:

[0025] Preparation raw materials: Potassium permanganate 2g, benzylamine 3g, vitamin B 6 1g, manganese sulfate 3g, zinc sulfate 3g, ammonium molybdate 3g, chitosan oligosaccharide 3g, potassium dihydrogen phosphate 2g, Aimite 0.7, starch 9g.

[0026] The preparation method of the present embodiment seed coating agent is the same as embodiment 1.

[0027] Using the seed coating agent prepared in this example, 100ml of the seed coating agent was added to 1kg of photonic cotton seeds and mixed evenly to treat the cotton seeds, and then sowed after drying, and then the indicators in the cotton growth process were measured. Among them, the effect of seed coating agent on the number of lateral roots and seedling height of cotton seedlings is shown in Table 1, the determination of root activity is shown in Table 2, the photosynthetic rate of leaves is shown in Table 2, the invertase ac...

Embodiment 3

[0029] The preparation method of the seed coating agent of the present embodiment is as follows:

[0030] Preparation raw materials: Potassium permanganate 1g, benzylamine 4g, vitamin B 6 4g, 5g of manganese sulfate, 4g of zinc sulfate, 4g of ammonium molybdate, 5g of chitosan oligosaccharide, 1g of potassium dihydrogen phosphate, 0.9 of amite, 9g of starch.

[0031] The preparation method of the present embodiment seed coating agent is the same as embodiment 1.

[0032] Use the seed coating agent prepared in this example to add 100 ml of the seed coating agent to 1 kg of photonic cotton seeds and mix evenly to treat the cotton seeds. After the treatment is dried, they are sown, and then the indicators in the cotton growth process are measured. Among them, the effect of seed coating agent on the number of lateral roots and seedling height of cotton seedlings is shown in Table 1, the determination of root activity is shown in Table 2, the photosynthetic rate of leaves is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com