A kind of air energy spray drying equipment

A technology of drying equipment and air energy, applied in the direction of spray evaporation, evaporator accessories, evaporation, etc., can solve the problems of wasting energy, polluting the production environment, and inability to keep warm, so as to reduce losses and ensure food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

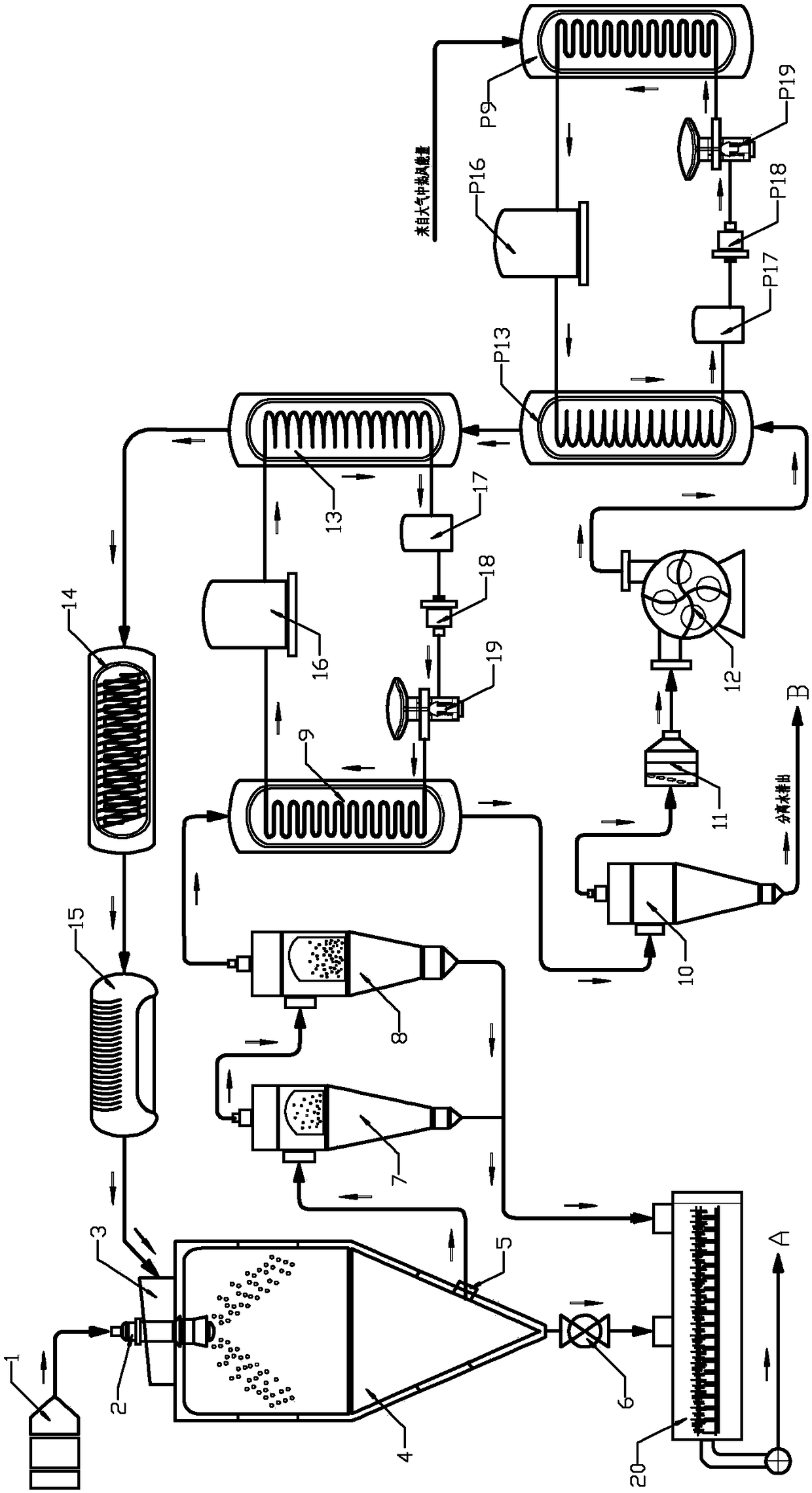

[0021] refer to figure 1 , a kind of air energy spray drying equipment, comprising drier main tower body 4, high temperature heat pump system and second high temperature heat pump system, high temperature heat pump system is composed of high temperature heat pump compressor 16, condenser 13, refrigerating The second high-temperature heat pump system consists of a second high-temperature heat pump compressor P16, a second condenser P13, and a second refrigerating The agent storage tank P17, the second filter P18, the second electronic expansion valve P19 and the second evaporator P9 are composed of a slurry sprayer 2 and a top hot air distributor 3 on the upper part of the dryer main tower body 4, and the dryer The bottom of the main tower body 4 is the powder outlet, and the middle and lower part of the main tower body 4 of the drier is provided with a hot air outlet 5, which is connected with the cyclone separator 7 and the electrostatic separator 8 in turn through the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com