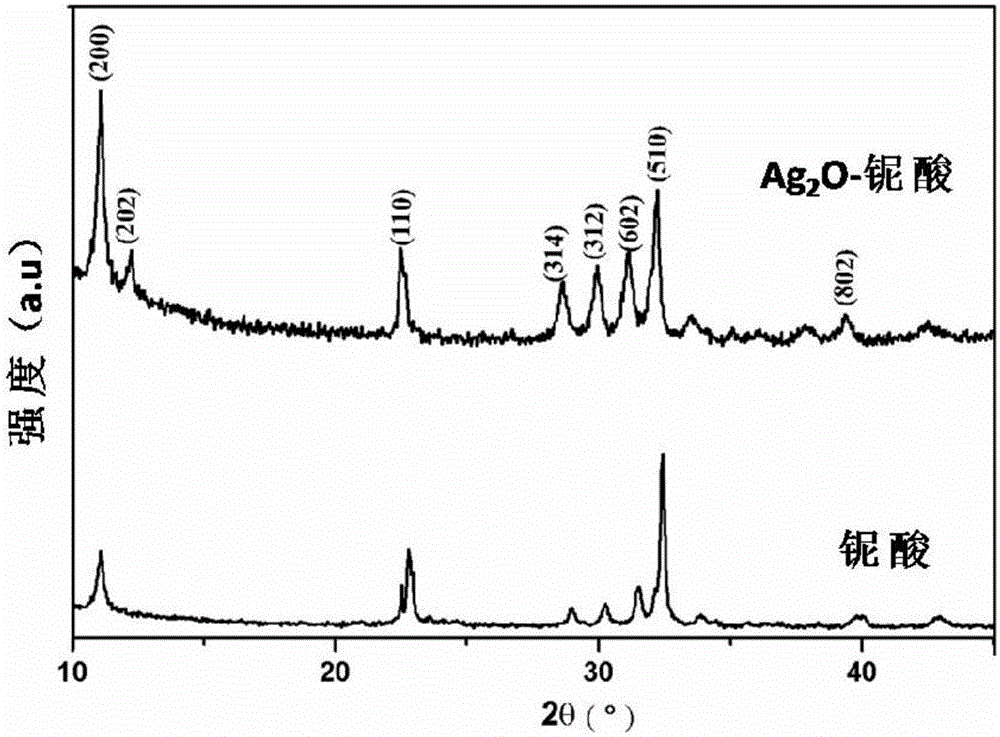

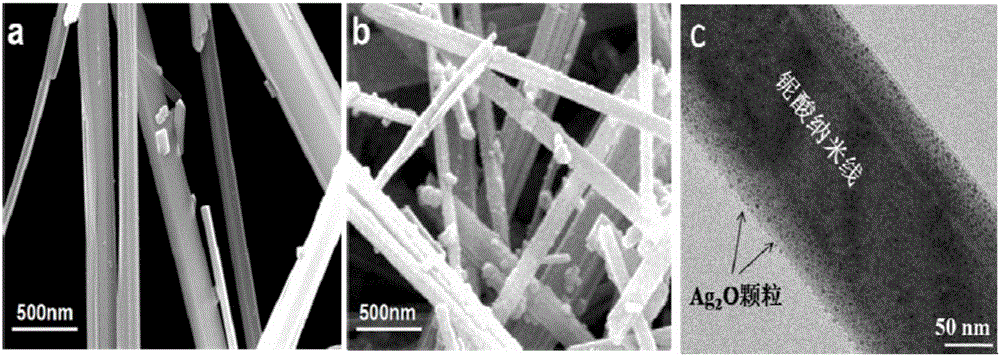

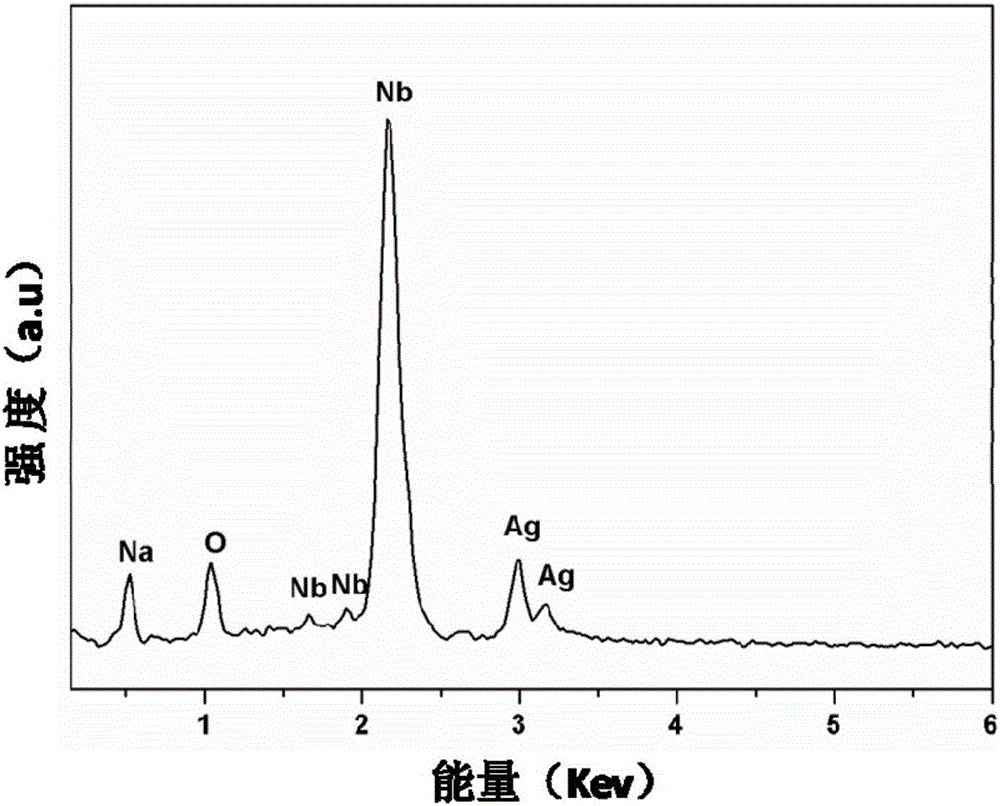

Preparation method of bifunctional Ag20/niobate composite adsorption material and application thereof

A technology of composite adsorption materials and nanocomposites, applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., can solve problems such as poor ion exchange performance and poor adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Put 8 parts of niobium pentachloride isopropanol solution with a concentration of 0.20mol / L in a polytetrafluoroethylene reactor; add 5 parts of NaOH solution with a concentration of 10mol / L to the above solution, stir for 0.5h, and fully Mix; then put the mixed solution in a polytetrafluoroethylene reactor, seal it and place it in a programmed oven, the heating and cooling rates are 1-2°C / min, and conduct a hydrothermal treatment at a temperature of 180°C for 2 hours. Take out the reactor, Cool to room temperature. Then the reaction products were washed with distilled water until neutral, and dried in an oven at a temperature of 80-100° C. for 48 hours to obtain niobic acid nanomaterials.

Embodiment 2

[0044] Put 8 parts of niobium pentachloride isopropanol solution with a concentration of 0.20mol / L in a polytetrafluoroethylene reactor; add 5 parts of NaOH solution with a concentration of 10mol / L to the above solution, stir for 0.5h, and fully Mix; then put the mixed solution in a polytetrafluoroethylene reactor, seal it and place it in a programmed oven, the heating and cooling rates are 1-2°C / min, and treat it with water at a temperature of 180°C for 2 hours, take out the reactor, and cool to room temperature. Then the reaction products were washed with distilled water until neutral, and dried in an oven at a temperature of 80° C. for 48 hours to obtain niobic acid nanomaterials. Weigh 3 samples of niobic acid nanomaterials, place them in a beaker containing 200mL deionized water, and use 1mol / L NaOH solution to adjust the pH of the solution to 11, and after standing for 24h, filter; the obtained product is placed in a concentration of 200mL In the silver nitrate solution ...

Embodiment 3

[0046] Put 6 parts of niobium pentachloride isopropanol solution with a concentration of 0.25mol / L in a polytetrafluoroethylene reaction kettle, add 3 parts of NaOH solution with a concentration of 11mol / L to the above solution, stir for 1h, and mix thoroughly ; Then put the mixed solution in a polytetrafluoroethylene reactor, seal it and place it in a programmed oven, heat up and cool down at a rate of 1°C / min, and treat it with hydrothermal treatment at a temperature of 170°C for 2 hours, take out the reactor, and cool to room temperature. Then the reaction products were washed with distilled water until neutral, and dried in an oven at a temperature of 80° C. for 24 hours to obtain niobic acid nanomaterials. Weigh 2 samples of niobic acid nanomaterials, place them in a beaker containing 200mL deionized water, and use 1mol / L NaOH solution to adjust the pH of the solution to 10, let it stand for 24h, and filter; the obtained product is placed in a concentration of 200mL In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com