Composite light catalyst for quickly and efficiently degrading rhodamine B and preparation method of composite light catalyst

A composite photocatalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long dye degradation time and low degradation efficiency, and achieve strong visible light response ability and good application Foreground, enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

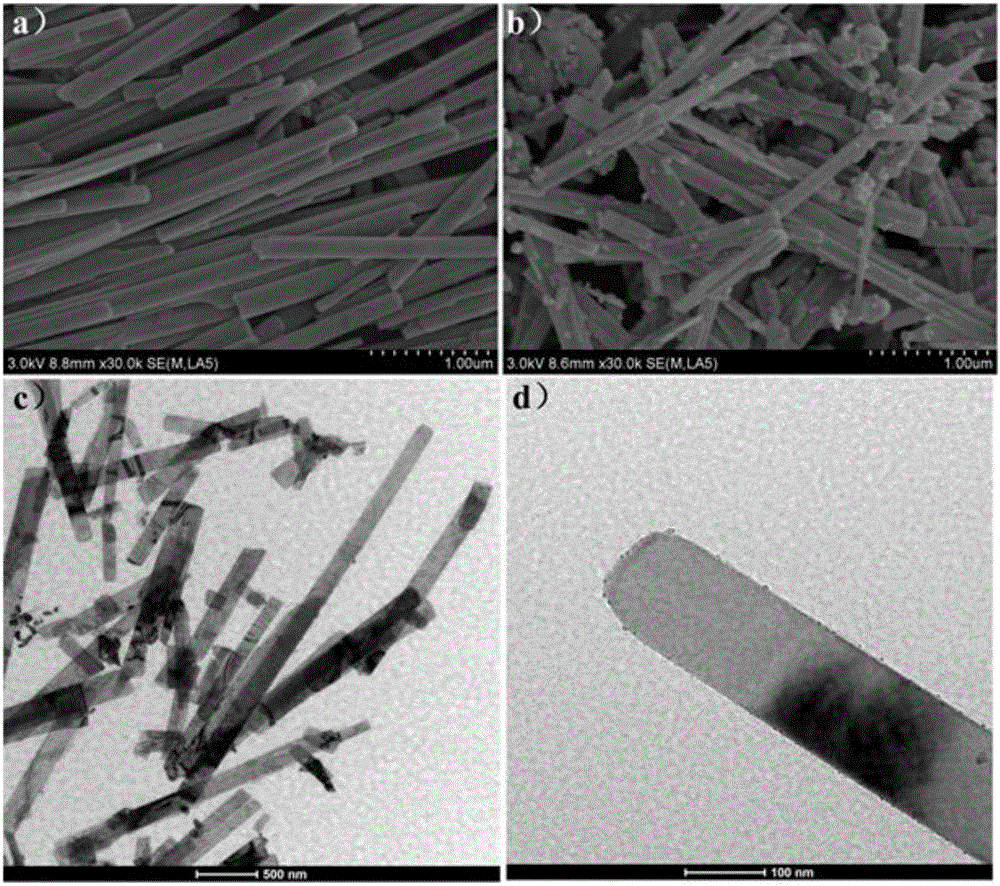

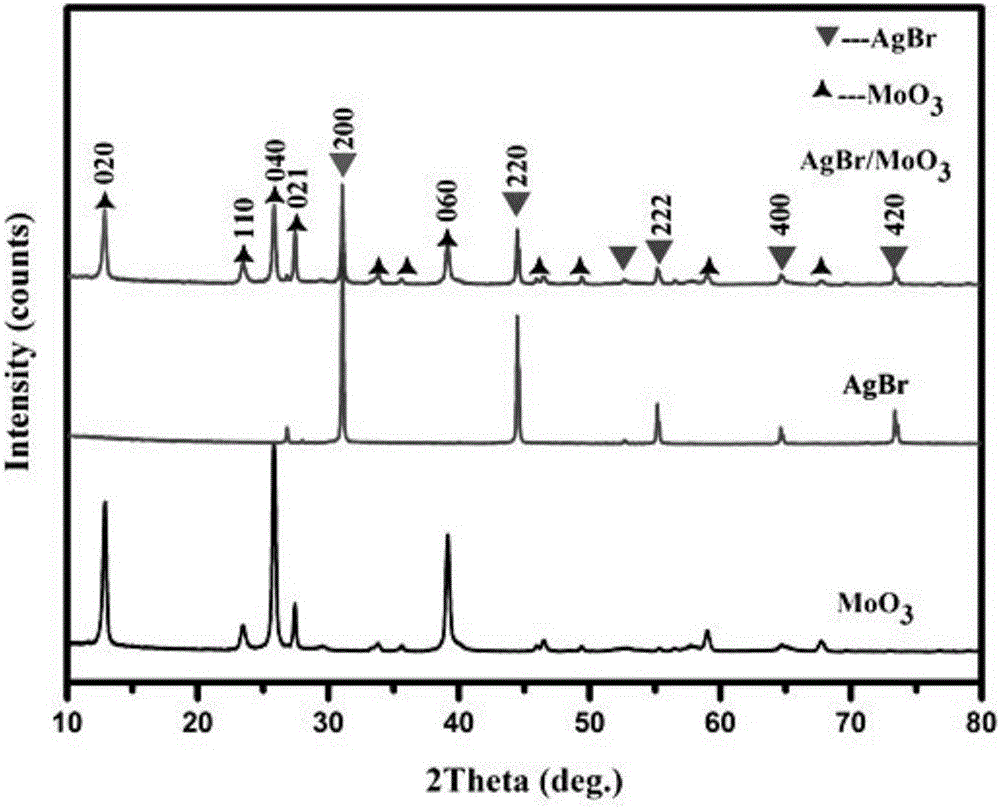

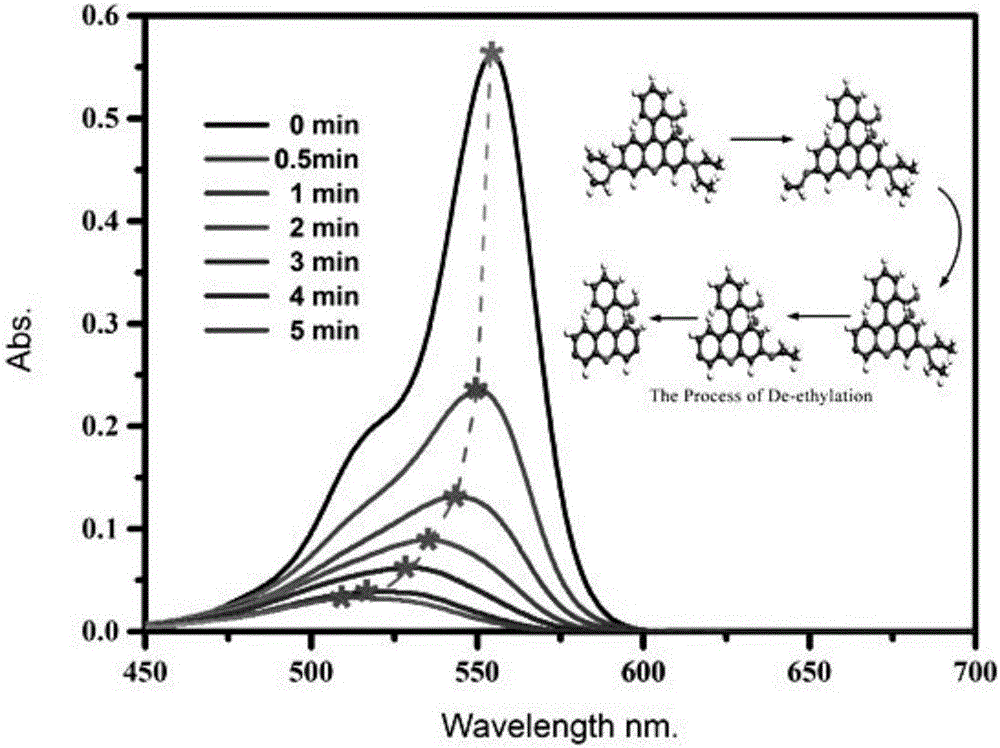

[0027] Weigh 0.72g of molybdenum powder, add 35mL of deionized water to a beaker, stir magnetically for 10min, then add 10mL of 30%wt H 2 o 2 After continuing to stir for 15 min, a light yellow solution A was obtained. Transfer the solution A to the polytetrafluoroethylene liner of the stainless steel reactor, and keep it warm at 180°C for 12h. The product obtained after the hydrothermal reaction was separated by filtration, washed twice with deionized water and absolute ethanol respectively, and dried in an oven at 70°C to prepare molybdenum trioxide nanobelts. Weigh 0.5 g of the prepared molybdenum trioxide and place it in a beaker, add 80 mL of absolute ethanol, add 12 mL of 0.1 M sodium bromide solution dropwise after magnetic stirring for 10 min, and obtain solution B after ultrasonication for 15 min; 12 mL of silver nitrate solution with a concentration of 0.1 M was slowly dropped into B dropwise, and magnetic stirring was continued for 12 h in a dark state. The stirr...

Embodiment 2

[0034] Weigh 0.72g of molybdenum powder and place it in a beaker, add 35mL of deionized water, stir magnetically for 10min, then add 10mL of 30%wt H 2 o 2Stirring was continued for 15 min to obtain light yellow solution A. Transfer the solution A to the polytetrafluoroethylene liner of the stainless steel reactor, and keep it warm at 180°C for 10h. After the hydrothermal reaction, the product was separated by filtration, washed twice with deionized water and absolute ethanol, and dried in an oven at 70°C to prepare molybdenum trioxide nanobelts. Weigh 0.5 g of the prepared molybdenum trioxide and place it in a beaker, add 80 mL of absolute ethanol, add 12 mL of 0.1 M sodium bromide solution dropwise after magnetic stirring for 10 min, and obtain solution B after ultrasonication for 15 min; 12 mL of silver nitrate solution with a concentration of 0.1 M was slowly added dropwise into solution B, and magnetic stirring was continued for 12 h in the dark. The stirred solution wa...

Embodiment 3

[0036] Weigh 0.72g of molybdenum powder and place it in a beaker, add 35mL of deionized water, stir magnetically for 10min, then add 10mL of 30%wt H 2 o 2 Stirring was continued for 15 min to obtain light yellow solution A. Transfer the solution A to the polytetrafluoroethylene liner of the stainless steel reactor, and keep it warm at 160°C for 12h. After the hydrothermal reaction, the product was separated by filtration, washed twice with deionized water and absolute ethanol, and dried in an oven at 70°C to prepare molybdenum trioxide nanobelts. Weigh 0.5 g of prepared molybdenum trioxide, add 80 mL of absolute ethanol to a beaker, add 12 mL of 0.1 M sodium bromide solution dropwise after magnetic stirring for 10 min, and obtain solution B after ultrasonication for 15 min; 12 mL of silver nitrate solution with a concentration of 0.1 M was slowly dropped into B dropwise, and magnetic stirring was continued for 12 h in a dark state. The stirred solution was separated by filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com