Preparation method of C3N4/SiO2 heterojunction photocatalyst

A C3N4, photocatalyst technology, applied in the field of photocatalytic material research, can solve the problems of high modification cost, complex process, difficult application of carbon nitride, etc., to achieve the effect of simple method, cheap raw materials, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation and naming of samples.

[0020] Weigh 2 g of melamine, add silicon dioxide nanoparticles in different proportions therein, and ultrasonically obtain a suspension for 4 hours; stir the resulting suspension at 90 degrees Celsius for 12 hours to completely volatilize the water to obtain a white solid; the obtained solid Heating to 540 degrees Celsius at a heating rate of 4 degrees per minute, and keeping at this temperature for 4 hours; after natural cooling, the C3N4 / SiO2 heterojunction photocatalyst can be obtained. The mass ratios of silica and melamine are 1:100, 3:100, 5:100, 10:100, 30:100, respectively, and the obtained samples are named: g-C 3 N 4 / SiO 2 -1,g-C 3 N 4 / SiO 2 -3,g-C 3 N 4 / SiO 2 -5,g-C 3 N 4 / SiO 2 -10 and g-C 3 N 4 / SiO 2 -30.

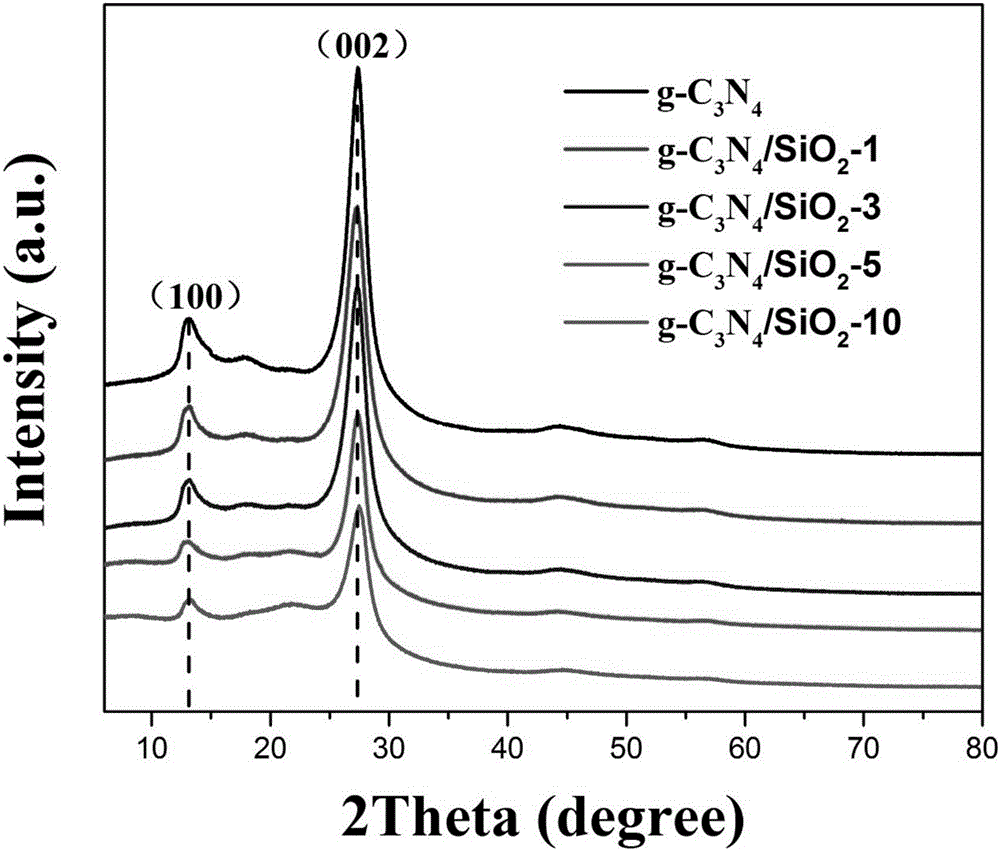

[0021] Embodiment 1: the crystal structure of sample

[0022] In the following examples, the crystal structure of the prepared samples was tested using a Rigaku D / max-2400 X-ray diff...

Embodiment 2

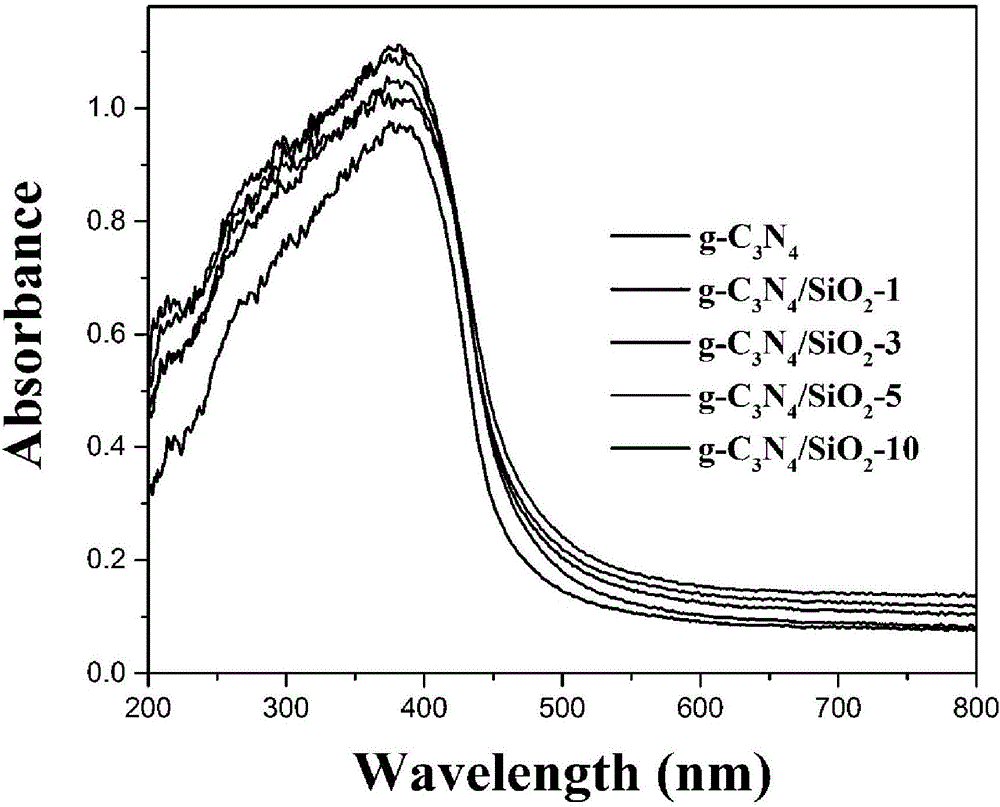

[0024] Embodiment 2: Optical property characterization of samples

[0025] A Hitachi U-3900 UV-Vis spectrophotometer was used to measure BaSO 4 As a reference, the scanning wavelength range is: 200-800nm, the slit width is 2nm, and the scanning speed is 600nm / min to detect the change of the optical properties of the sample.

[0026] Changes in the electronic properties lead to changes in the photophysical properties of the material, resulting in changes in the shape and intensity of the spectrum. figure 2 It is the UV diffuse reflectance spectrum of g-C3N4 and g-C3N4 / SiO2 composite photocatalyst. It can be seen from the figure that the band edge of the composite photocatalyst g-C3N4 / SiO2 has an obvious red shift. This is because SiO2 can increase the absorption of the material in the visible light region. These characteristics are conducive to the improvement of the visible light activity of g-C3N4 / SiO2. .

[0027] Rhodamine B dye and 2,4-dichlorophenol were used as target...

Embodiment 3

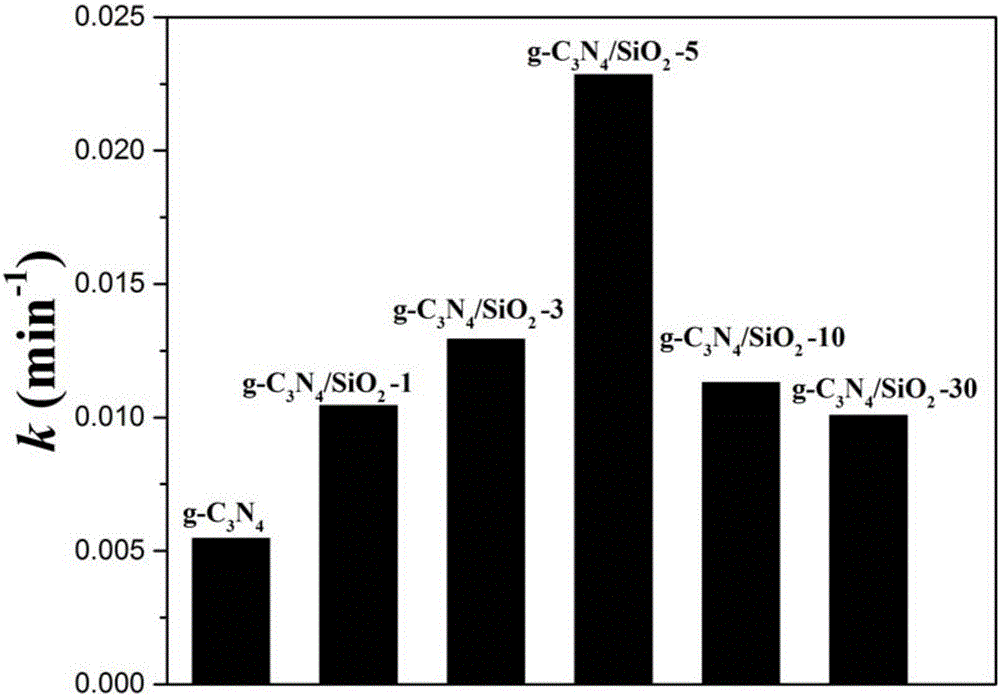

[0028] Embodiment 3: the ability of the prepared sample to degrade rhodamine B.

[0029] Taking rhodamine B as the target pollutant, the catalytic activity of g-C3N4 and g-C3N4 / SiO2 composite photocatalysts was studied. from image 3 It can be seen that all the g-C3N4 photocatalysts modified by SiO2 showed a higher photocatalytic reaction rate than the original g-C3N4, and C3N4 / SiO2-5 showed the highest photocatalytic activity, which was about the original g-C3N4 4.81 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com