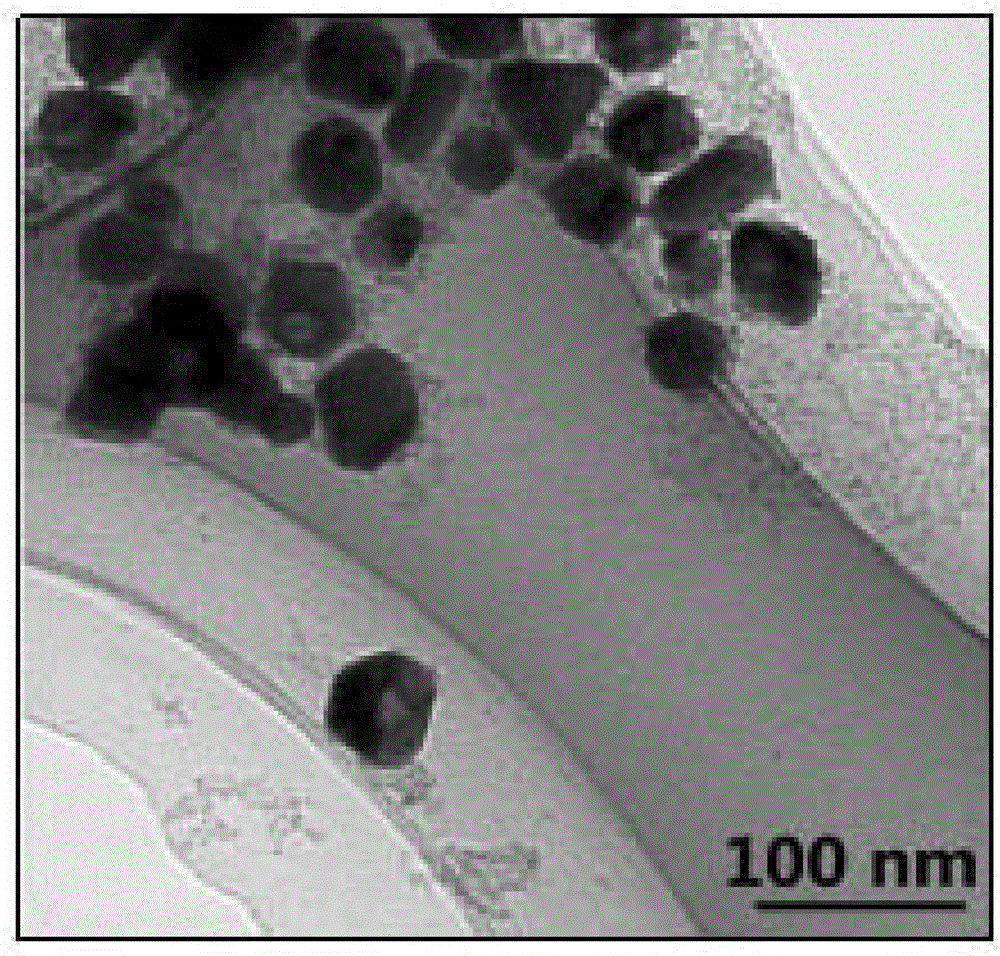

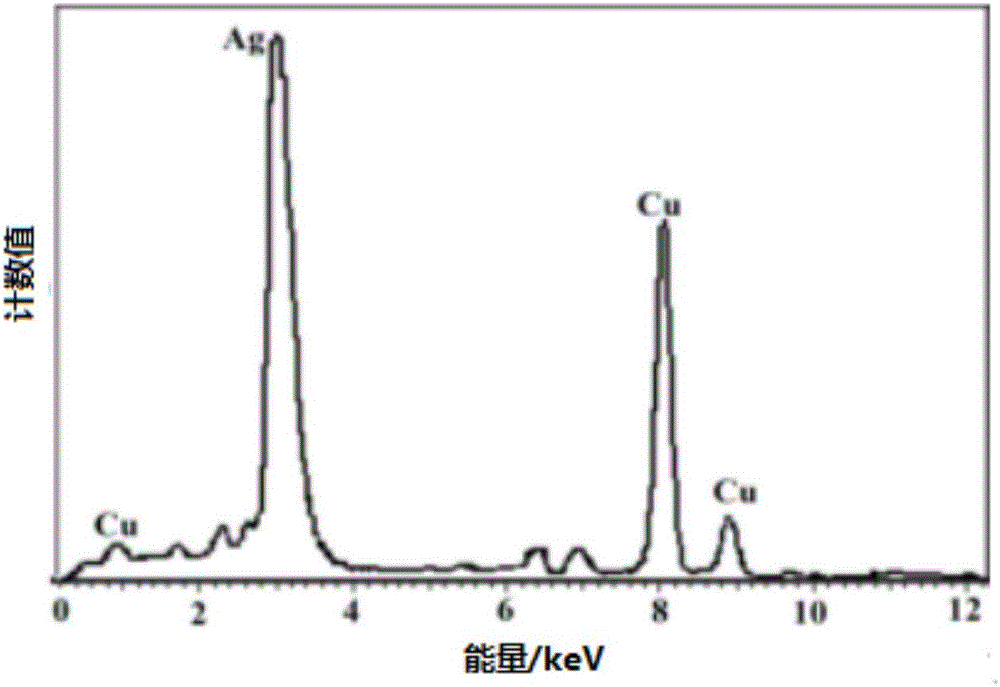

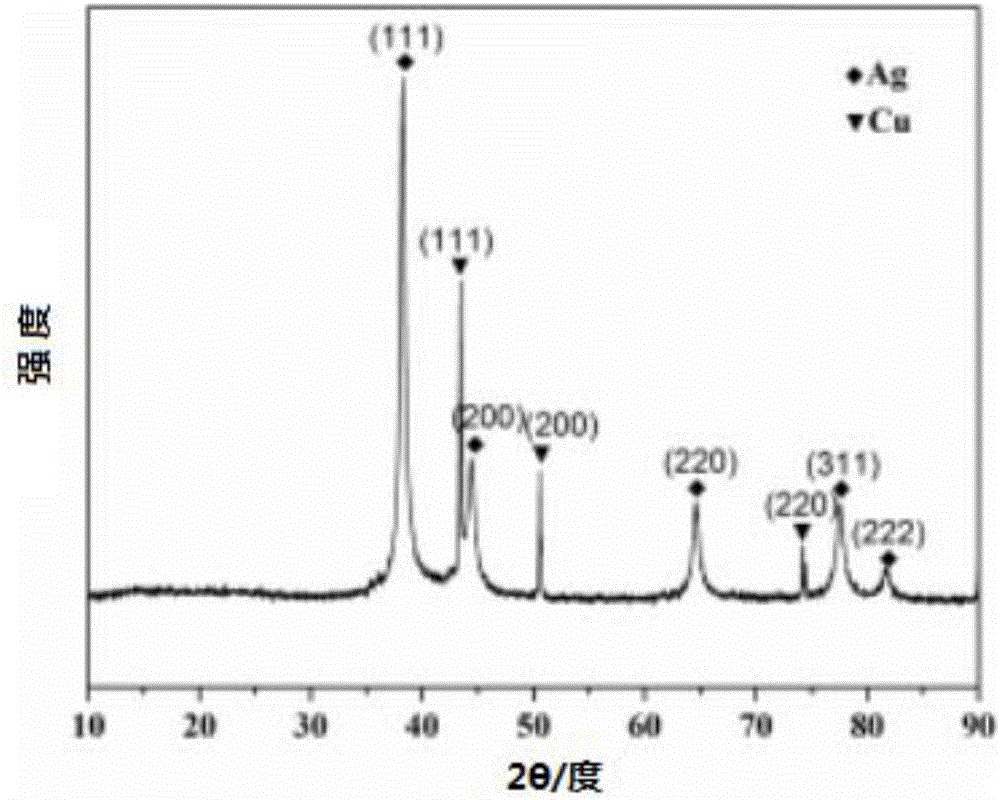

Cu-Ag bimetallic nano material, preparation method and application thereof

A bimetallic nano- and nano-sol technology, applied in the field of nano-materials, can solve the problems of large particle size and long time of copper-silver nano-materials, and achieve the effects of short reaction time, uniform distribution and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] An embodiment of the present invention provides a method for preparing a Cu-Ag bimetallic nanomaterial, comprising the following steps:

[0032] Prepare the polyol solution of the silver nitrate of 5-20mmol / L, the polyol solution of the polyvinylpyrrolidone of 40-100mmol / L and the polyol solution of the copper acetate of 5-20mmol / L; Wherein polyol comprises ethylene glycol, propane One of triol and n-heptanol.

[0033] The polyol solution of silver nitrate and the polyol solution of polyvinylpyrrolidone are mixed and stirred and dissolved in a volume ratio of 1:1-1.2 to obtain the first solution, and the first solution is subjected to microwave heating treatment to obtain Ag nano-sol, and the microwave power is 520-650W, processing time is 90-120s;

[0034] The n-heptanol solution of copper acetate and the Ag nano sol are mixed and stirred and dissolved in a volume ratio of 1:1-1.2 to obtain a second solution, and the molar ratio of Cu and Ag in the second solution is ...

Embodiment 1

[0041] Embodiment 1 of the present invention provides a kind of Cu-Ag bimetallic nano material, and its preparation method is as follows:

[0042]S101, prepare the n-heptanol solution of silver nitrate of 10mmol / L, the n-heptanol solution of 60mmol / L polyvinylpyrrolidone, the n-heptanol solution of 20mmol / L copper acetate;

[0043] S102. Mix the n-heptanol solution of silver nitrate with the n-heptanol solution of polyvinylpyrrolidone at a volume ratio of 1:1.2, stir magnetically for 120s until completely dissolved, and obtain the first solution. Transfer the first solution to a microwave oven In the polyethylene container tank in the chemical reactor, adjust the microwave power to 550W, heat for 110s, and obtain Ag nano-sol after cooling to room temperature;

[0044] S103, mix the n-heptanol solution of copper acetate and the Ag nano sol in a volume ratio of 1:1.1, stir magnetically for 90s until completely dissolved, and obtain a second solution, the molar ratio of Cu and Ag...

Embodiment 2

[0047] Embodiment 2 of the present invention provides a kind of Cu-Ag double metal nano material, and its preparation method is as follows:

[0048] S201, prepare the ethylene glycol solution of 10mmol / L silver nitrate, the ethylene glycol solution of 75mmol / L polyvinylpyrrolidone, the ethylene glycol solution of 10mmol / L copper acetate;

[0049] S202. Mix the ethylene glycol solution of silver nitrate with the ethylene glycol solution of polyvinylpyrrolidone in a volume ratio of 1:1, stir magnetically for 90 seconds until completely dissolved, and obtain the first solution. Transfer the first solution to a microwave oven In the polyethylene container tank in the chemical reactor, adjust the microwave power to 600W, heat for 105s, and obtain Ag nano-sol after cooling to room temperature;

[0050] S203, mix the ethylene glycol solution of copper acetate and the Ag nano sol in a volume ratio of 1:1.1, and stir magnetically for 100s until completely dissolved to obtain a second s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com