Flexible production line for axle box body machining and machining method

A flexible production line and processing method technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of affecting tooling accuracy, long auxiliary time, etc., to improve production efficiency, simplify the work department, and improve the technological level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

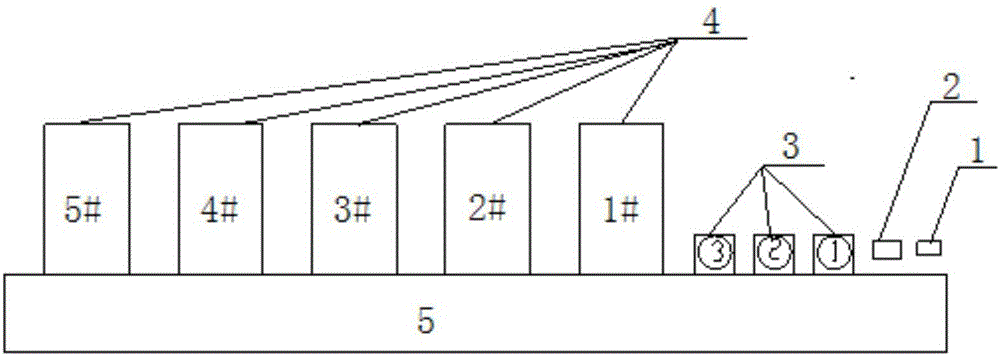

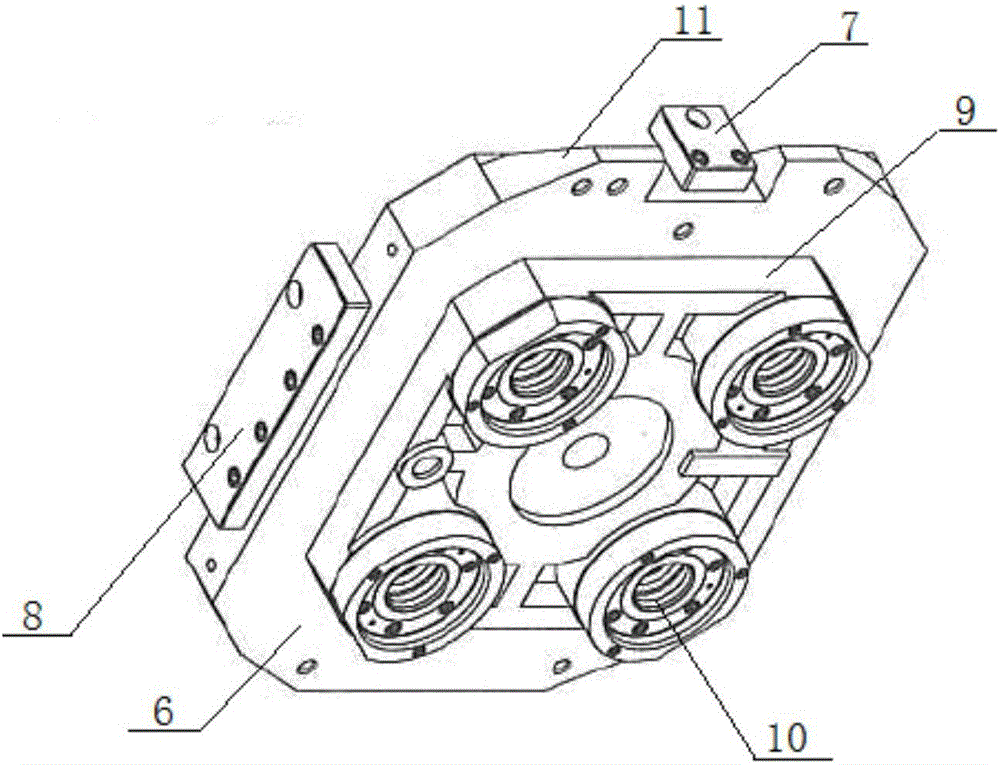

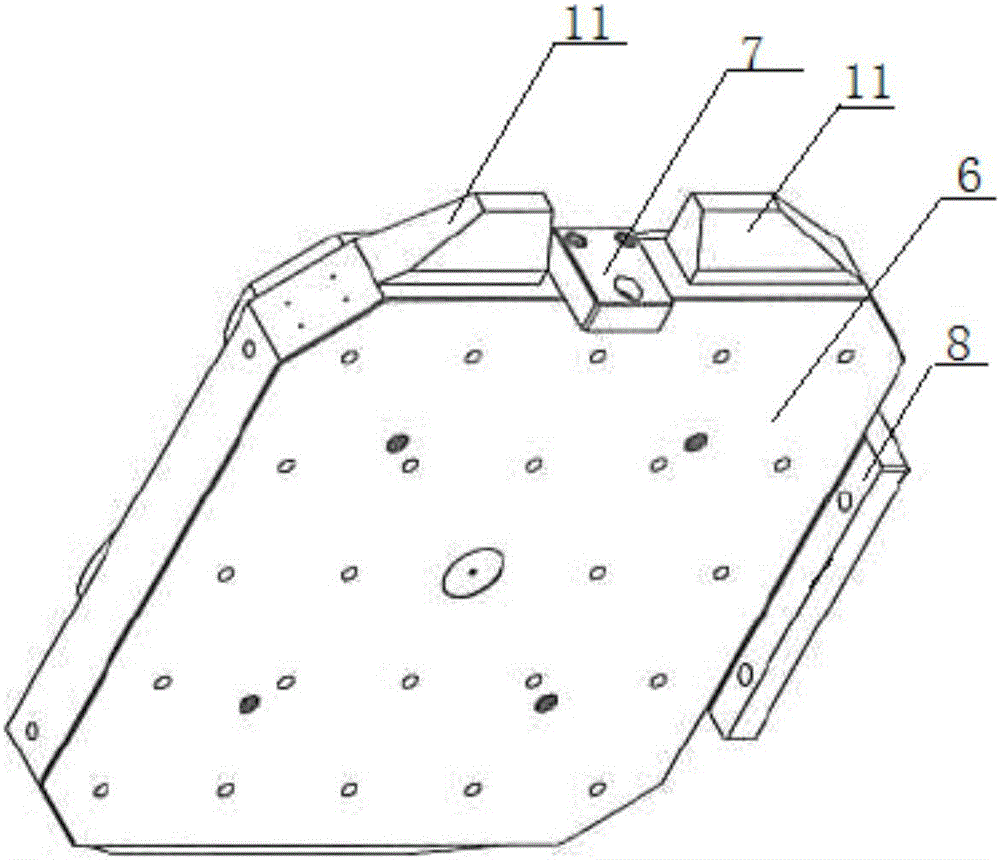

[0029] Such as Figures 1 to 5 As shown, a flexible production line for shaft box processing provided by the present invention, the production line includes a tool setting instrument 1, a control system, a linear pallet system 5, a plurality of machining centers 4 and loading and unloading stations 3, and the operating platforms are arranged on the same side , the linear pallet system 5 includes a machine tool and multiple pallets 6, the top of the pallet 6 can fix the axis box, and the bottom can be detachably fixed to the machine tool, each pallet 6 can correspond to a machining center 4, and the control system can control each machining center 4 Numerical control machining is carried out to the axle boxes on the pallet 6 respectively.

[0030] Such as figure 1 As shown, in this embodiment, the entire shaft box processing flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com