Preparation method for alternate multi-layered polymer microcellular foaming material

A microcellular foaming material and polymer technology, applied in the field of polymer foaming material preparation, can solve the problems of small cell density and expansion ratio, non-green foaming agent, poor performance, etc., and achieve a small average diameter , good foaming effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

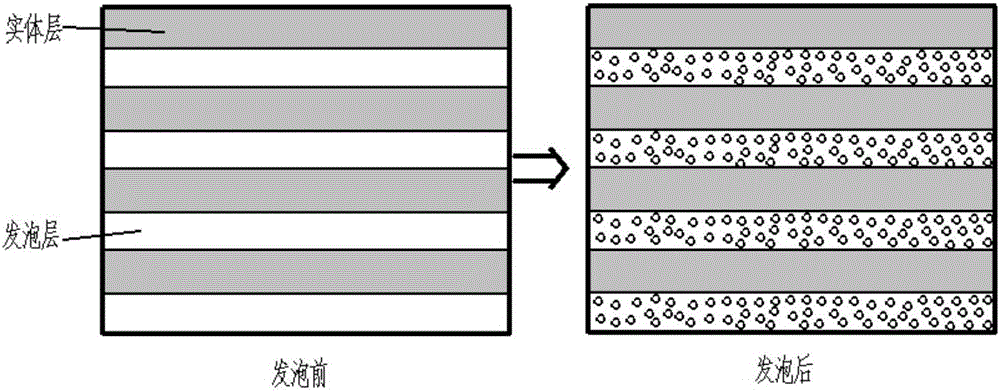

[0025] In this embodiment, a method for preparing an alternating multilayer polymer microcellular foaming material comprises the following steps:

[0026] (1) A 32-layer polypropylene (PP) / ethylene-octene copolymer (POE) (mass ratio of 80 / 20) alternating multi-layer sheet was prepared using an alternating multi-layer co-extrusion equipment to prepare length×width×thickness About 10×5×2mm 3 The cuboid spline of ;

[0027] (2) Place the PP / POE alternating multilayer cuboid sample prepared in step (1) in an autoclave, and at a saturation temperature of 50°C and a saturation pressure of 15MPa, lead to supercritical carbon dioxide. After continuous saturation for 5 hours, the high pressure The pressure in the kettle was reduced to atmospheric pressure within 0.5s, thereby obtaining a foamed sample with alternately arranged PP solid layers and POE foamed layers. The prepared foamed sample had an average cell diameter of 2.53 μm and a cell density of 1.98×10 10 cells / cm 3 .

Embodiment 2

[0029] In this embodiment, a method for preparing an alternating multilayer polymer microcellular foaming material comprises the following steps:

[0030] (1) Prepare a 32-layer PP / POE (mass ratio of 80 / 20) alternating multi-layer sheet using an alternating multi-layer co-extrusion equipment, and prepare a length×width×thickness of about 10×5×2mm 3 The cuboid spline of ;

[0031] (2) Place the PP / POE alternating multilayer cuboid sample prepared in step (1) in an autoclave, and at a saturation temperature of 60°C and a saturation pressure of 15MPa, lead to supercritical carbon dioxide. After continuous saturation for 5 hours, the high pressure The pressure in the kettle was reduced to atmospheric pressure within 0.5s, thereby obtaining a foamed sample with alternately arranged PP solid layers and POE foamed layers. The average cell diameter of the prepared foam sample is 2.4 μm, and the cell density is 2.1×1010cells / cm 3 . Compared with Example 1, the average cell diameter ...

Embodiment 3

[0033] In this embodiment, a method for preparing an alternating multilayer polymer microcellular foaming material comprises the following steps:

[0034] (1) Prepare a 32-layer PP / POE (mass ratio of 80 / 20) alternating multi-layer sheet using an alternating multi-layer co-extrusion equipment, and prepare a length×width×thickness of about 10×5×2mm 3 The cuboid spline of ;

[0035] (2) Place the PP / POE alternating multilayer cuboid sample prepared in step (1) in an autoclave, and at a saturation temperature of 70°C and a saturation pressure of 15MPa, lead to supercritical carbon dioxide. After continuous saturation for 5 hours, the high pressure The pressure in the kettle was reduced to atmospheric pressure within 0.5s, thereby obtaining a foamed sample with alternately arranged PP solid layers and POE foamed layers. The average cell diameter of the prepared foamed sample is 2.21 μm, and the cell density is 2.72×10 10 cells / cm 3 . Compared with Examples 1 and 2, the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com