Synthetic method of 4-vinylbenzocyclobutene

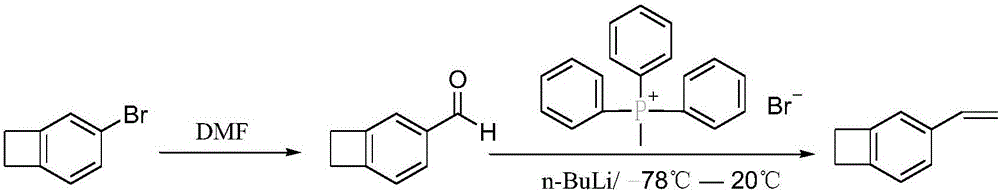

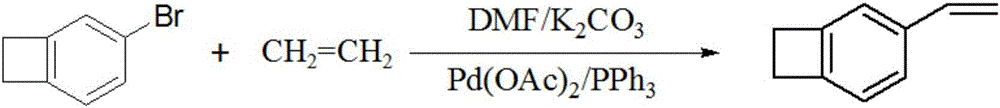

A technology of bromobenzocyclobutene and vinylbenzene is applied in the synthesis field of 4-vinylbenzocyclobutene, can solve the problems of low comprehensive yield, complicated operation, harsh ultra-low temperature conditions, etc., and achieves simple process, Simple operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of synthetic method of 4-vinyl benzocyclobutene, comprises the steps: add the solvent that dissolves potassium carbonate in autoclave, then 4-bromo benzocyclobutene and catalyst are added in solvent, close still cover Use nitrogen to replace the air in the autoclave three times, then feed ethylene gas to make the reaction pressure reach 1MPa, seal and heat up to 70°C, stir and react for 5 hours, the pressure drops to 0.5MPa, stop heating, and obtain the reaction solution. Separate the phases to obtain an oil phase and an aqueous phase; the aqueous phase was extracted twice with ether, and the obtained ether phase was combined with the oil phase, then washed once with deionized water and saturated sodium chloride solution, and dried over anhydrous sodium sulfate for 4 hours Above, after drying, the solvent was removed by rotary evaporation, concentrated into a light yellow oily liquid, and purified by vacuum distillation using a high vacuum oil pump, and the fracti...

Embodiment 2

[0025] A kind of synthetic method of 4-vinyl benzocyclobutene, comprises the steps: add the solvent that dissolves potassium carbonate in autoclave, then 4-bromo benzocyclobutene and catalyst are added in solvent, close still cover Use nitrogen to replace the air in the autoclave three times, then feed ethylene gas to make the reaction pressure reach 10MPa, seal and heat up to 90°C, stir and react for 8 hours, the pressure drops to 3MPa, stop heating, and obtain the reaction solution. phase to obtain an oil phase and an aqueous phase; the aqueous phase was extracted twice with ether, and the obtained ether phase was combined with the oil phase, then washed once with deionized water and saturated sodium chloride solution, and dried over anhydrous sodium sulfate for more than 4 hours After drying, the solvent was removed by rotary evaporation, concentrated into a light yellow oily liquid, and purified by vacuum distillation using a high vacuum oil pump, and the fractions at 75-80...

Embodiment 3

[0027] A kind of synthetic method of 4-vinyl benzocyclobutene, comprises the steps: add the solvent that dissolves potassium carbonate in autoclave, then 4-bromo benzocyclobutene and catalyst are added in solvent, close still cover Use nitrogen to replace the air in the autoclave three times, then feed ethylene gas to make the reaction pressure reach 4MPa, seal and heat up to 80°C, stir and react for 6 hours, the pressure drops to 2.5MPa, stop heating, and obtain the reaction solution. Separate the phases to obtain an oil phase and an aqueous phase; the aqueous phase was extracted twice with ether, and the obtained ether phase was combined with the oil phase, then washed once with deionized water and saturated sodium chloride solution, and dried over anhydrous sodium sulfate for 4 hours Above, after drying, the solvent was removed by rotary evaporation, concentrated into a light yellow oily liquid, and purified by vacuum distillation using a high vacuum oil pump, and the fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com