Phosphor-fluorine flame retardant and preparation method thereof

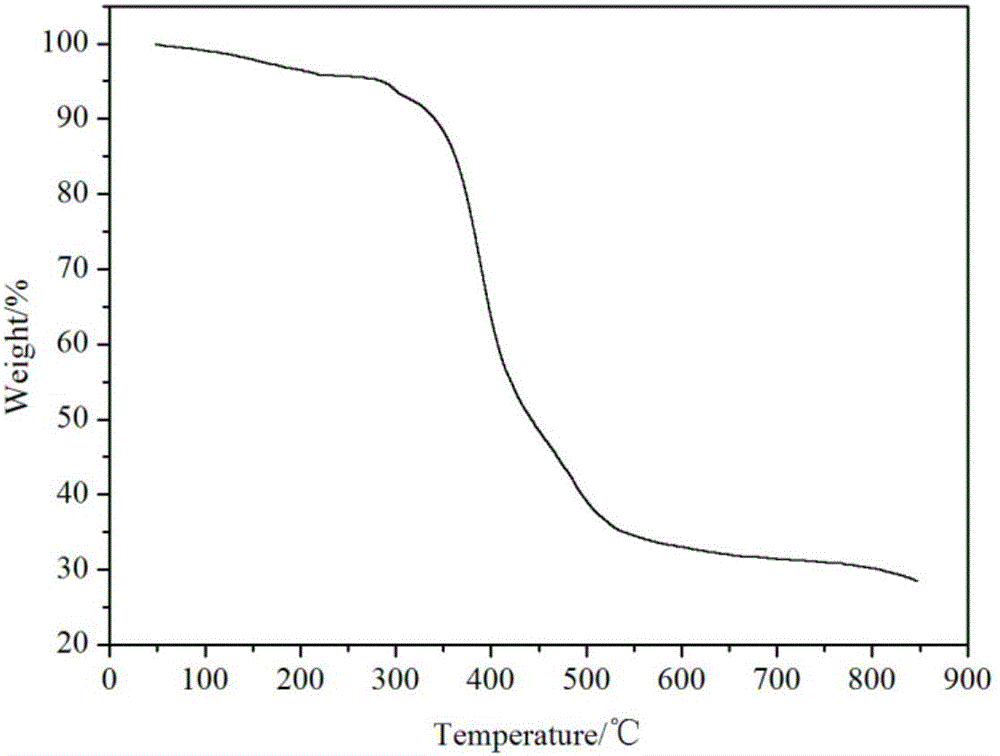

A technology of flame retardants and precipitants, applied in the field of flame retardants, can solve problems such as difficulty in finding substitutes, environmental and human health hazards, and hinder the development of halogenated flame retardants, so as to reduce heat and achieve better flame retardant effects Good, good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

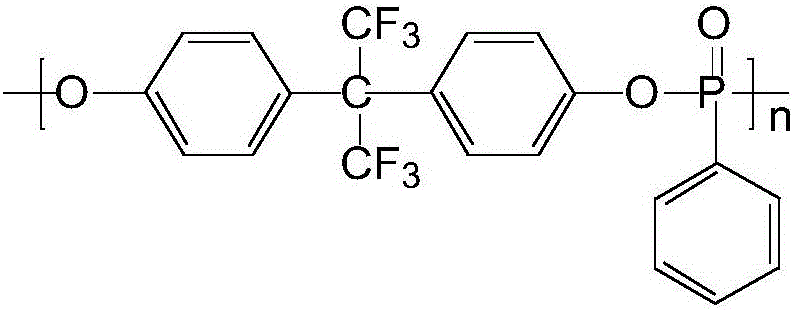

Method used

Image

Examples

Embodiment 1

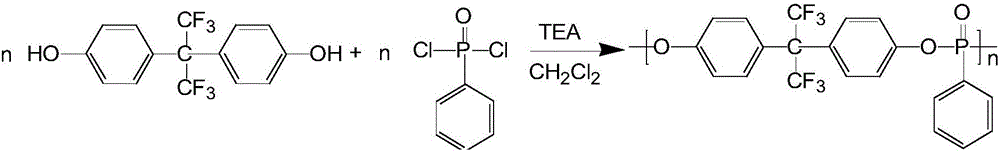

[0029] A preparation method of phosphorus fluorine flame retardant, comprising the following steps:

[0030] Step 1: Take 6.72g (20mmol) bisphenol AF and pour it into a three-necked flask with a capacity of 250ml containing 60ml of dichloromethane, stir to make bisphenol AF fully dissolve in dichloromethane to obtain a dichloromethane solution of bisphenol AF , add the triethylamine of 4.44g (44mmol) in the three-necked flask of the methylene chloride solution that fills bisphenol AF, place the three-necked flask adding triethylamine in ice-water bath, stir with magnetic stirrer, simultaneously with The constant pressure dropping funnel slowly added the dichloromethane solution of phenylphosphoryl dichloride to the three-necked flask, so that bisphenol AF and phenylphosphoryl dichloride reacted under the catalysis of triethylamine, in which phenylphosphoryl dichloride Dichloro is 3.94g (20mmol), and the volume of dichloromethane is 10ml, and the rate of addition is controlled ...

Embodiment 2

[0034] A preparation method of phosphorus fluorine flame retardant, comprising the following steps:

[0035] Step 1: Take 33.6g (0.1mol) of bisphenol AF and pour it into a three-necked flask with a capacity of 1000ml containing 250ml of dichloromethane. Bisphenol AF is fully dissolved in dichloromethane, and 22.2g (0.22 mol) of triethylamine for catalysis, the three-necked flask was placed in an ice-water bath, stirred with a magnetic stirrer, and at the same time, the dichloromethane solution of phenylphosphoryl dichloride was slowly added dropwise to the three-necked flask with a constant pressure dropping funnel , wherein phenylphosphoryl dichloride is 19.7g (0.1mol), and the volume of dichloromethane is 50ml, and the rate of addition is controlled so that the dichloromethane solution of phenylphosphoryl dichloride is added dropwise in 1.2 hours;

[0036] Step 2: After the dropwise addition, continue to stir the solution in the three-necked flask for 20 minutes until the te...

Embodiment 3

[0038] Embodiment 3: a kind of preparation method of phosphorus fluorine flame retardant comprises the following steps:

[0039] Step 1: Take 33.6g (0.1mol) of bisphenol AF and pour it into a three-necked flask with a capacity of 1000ml containing 250ml of dichloromethane. Bisphenol AF is fully dissolved in dichloromethane, and 22.2g (0.22 mol) of triethylamine for catalysis, the three-necked flask was placed in an ice-water bath, stirred with a magnetic stirrer, and at the same time, the dichloromethane solution of phenylphosphoryl dichloride was slowly added dropwise to the three-necked flask with a constant pressure dropping funnel , wherein phenylphosphoryl dichloride is 17.73g (0.09mol), and the volume of dichloromethane is 50ml, and the rate of addition is controlled so that the dichloromethane solution of phenylphosphoryl dichloride is added dropwise in 1.2 hours;

[0040] Step 2: After the dropwise addition, continue to stir the solution in the three-necked flask for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com