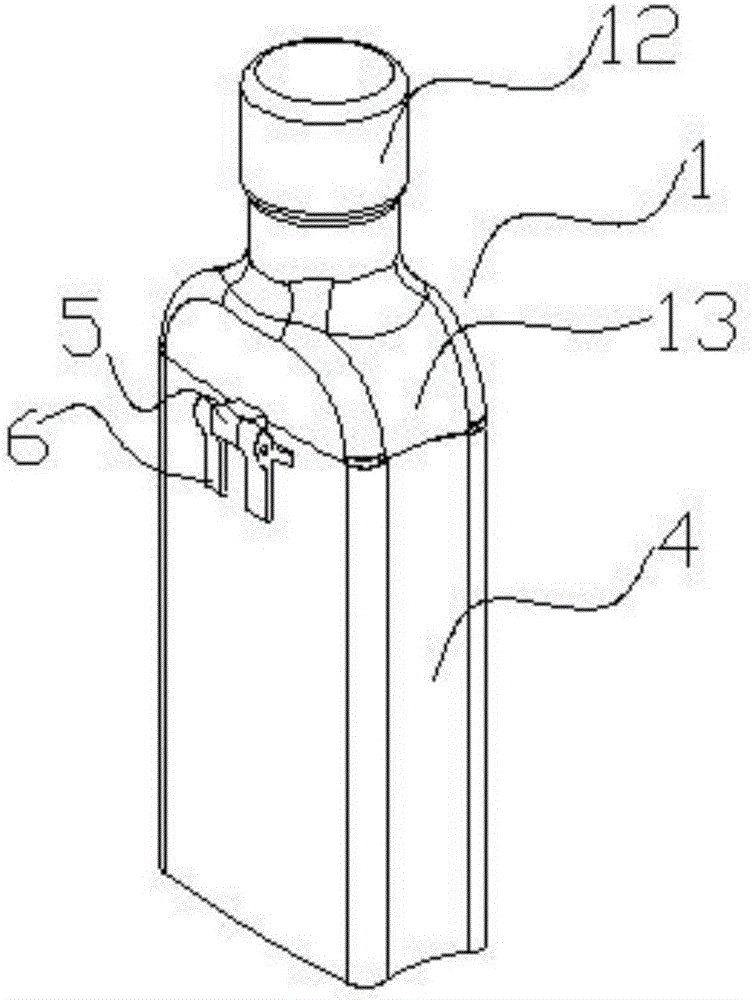

High barrier anti-aging water cup and preparation method thereof

An anti-aging, high-barrier technology, applied in the direction of drinking water vessels, etc., can solve the problems of poor barrier properties, poor oxidation resistance and radiation resistance, etc., and achieve high barrier properties, improve barrier properties, and improve barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

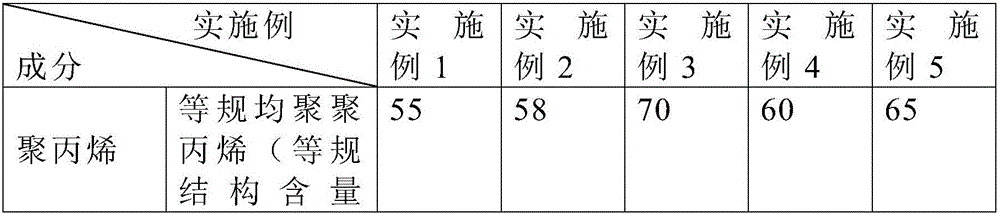

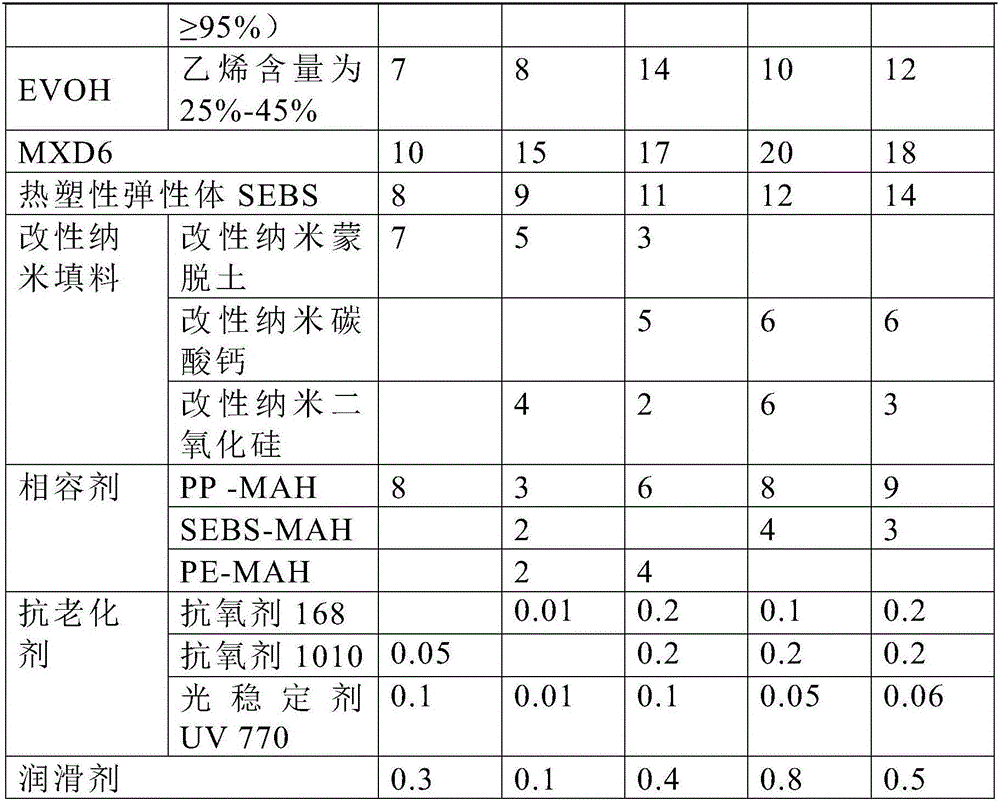

Embodiment 1

[0051] To prepare modified nanofillers, dissolve one part of silane coupling agent KH-560 in four parts of 75% ethanol solution, ultrasonically disperse at room temperature for 20 minutes, then add four parts of nanoparticles, heat to 80°C while stirring, and react at constant temperature for 5 hours After that, it was suction filtered, washed three times with absolute ethanol, and dried in a vacuum oven at 50°C to obtain the target modified nanoparticles.

[0052] Weigh the raw materials according to the composite material composition and weight percentage of the high-barrier anti-aging water cup described in Example 1 of Table 1, and mix each raw material in a high-mixer, and discharge the mixed raw materials from the high-mixer , poured into the feeding machine, fed into the twin-screw extruder by the feeder, extruded and granulated; the prepared granulated was added to the barrel of the high-speed injection molding machine, and the barrel was heated to 210 ° C at the same t...

Embodiment 2

[0055] To prepare modified nano fillers, dissolve one part of silane coupling agent KH-560 in four parts of 75% ethanol solution, ultrasonically disperse at room temperature for 30 minutes, then add four parts of nanoparticles, heat to 85°C while stirring, and react at constant temperature for 7 hours Afterwards, filter with suction, wash with absolute ethanol three times, and place it in a vacuum drying oven at 60° C. to dry to obtain the target modified nanoparticles.

[0056] Take the raw materials by the composition of the composite material of the transparent anti-aging water cup described in Example 2 of Table 1 and the weight percentage thereof, and mix each raw material in a high mixer, and discharge the mixed raw materials from the high mixer, Pour it into the feeding machine, feed it into the twin-screw extruder from the feeder, extrude and granulate, add the prepared granulation to the barrel of the high-speed injection molding machine, and heat the barrel to 230°C a...

Embodiment 3

[0059] To prepare modified nano fillers, dissolve one part of silane coupling agent KH-560 in four parts of 75% ethanol solution, ultrasonically disperse at room temperature for 40 minutes, then add four parts of nanoparticles, heat to 90°C while stirring, and react at constant temperature for 6 hours After that, it was suction filtered, washed three times with absolute ethanol, and dried in a vacuum oven at 55°C to obtain the target modified nanoparticles.

[0060] Take the raw materials by the composite material composition and weight percentage of the transparent anti-aging water cup described in Example 3 of Table 1, and mix each raw material in a high mixer, and discharge the mixed raw materials from the high mixer, Pour into the feeding machine, feed it into the twin-screw extruder from the feeder, extrude and granulate, add the prepared granulation to the barrel of the high-speed injection molding machine, and heat the barrel to 250 ° C at the same time, and heat it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com