Bacteriostatic board for adjusting indoor microenvironment and preparation method of bacteriostatic board

A micro-environment and regulating room technology, applied in the field of environmental protection building boards, can solve problems such as failure to meet safety and environmental protection, affect human health, and many types of pollutants, and achieve the effect of improving indoor micro-environment, improving human resistance, and increasing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

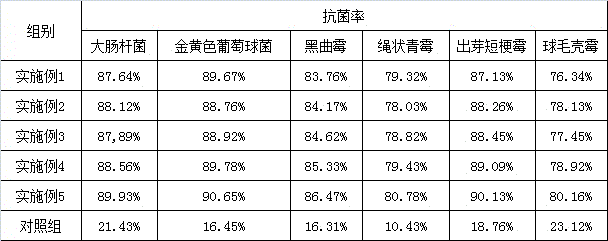

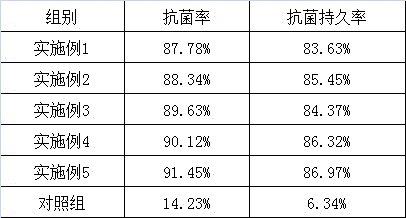

Examples

Embodiment 1

[0020] An antibacterial plate for adjusting indoor microenvironment, made of the following raw materials in parts by weight: 30 parts of wood powder, 12 parts of bamboo charcoal, 6 parts of coconut shell, 12 parts of peanut shell, 6 parts of talcum powder, 50 parts of plastic powder, 12 parts of cassia seeds, 4 parts of angelica, 6 parts of ginkgo, 8 parts of mint, 4 parts of lemon, and 12 parts of eucalyptus leaves.

[0021] The preparation method of the antibacterial plate for adjusting the indoor microenvironment, comprises the following steps:

[0022] 1) Place the formulated amount of wood powder at 220°C for carbonization treatment for 10 seconds, and obtain modified charcoal powder after cooling;

[0023] 2) Put the formulated amount of bamboo charcoal, coconut shell, and peanut shell into a pulverizer for crushing and mixing, then add the formulated amount of talc powder into the mixer, and stir at a constant speed of 600r / min for 10 minutes to obtain a mixed powder fo...

Embodiment 2

[0028] An antibacterial plate for adjusting indoor microenvironment, made of the following raw materials in parts by weight: 42 parts of wood powder, 24 parts of bamboo charcoal, 12 parts of coconut shell, 24 parts of peanut shell, 12 parts of talcum powder, 74 parts of plastic powder, 18 parts of cassia seeds, 10 parts of angelica, 12 parts of ginkgo, 14 parts of mint, 10 parts of lemon, and 18 parts of eucalyptus leaves.

[0029] The preparation method of the antibacterial plate for adjusting the indoor microenvironment, comprises the following steps:

[0030] 1) Place the formulated amount of wood powder at 230°C for carbonization treatment for 20 seconds, and obtain modified charcoal powder after cooling;

[0031] 2) Put the formulated amount of bamboo charcoal, coconut shell, and peanut shell into a pulverizer for crushing and mixing, then add the formulated amount of talcum powder into the mixer, and stir at a constant speed of 800r / min for 15 minutes to obtain a mixed p...

Embodiment 3

[0036] An antibacterial plate for adjusting indoor microenvironment, made of the following raw materials in parts by weight: 34 parts of wood powder, 16 parts of bamboo charcoal, 8 parts of coconut shell, 16 parts of peanut shell, 8 parts of talcum powder, 58 parts of plastic powder, 14 parts of cassia seeds, 6 parts of angelica, 8 parts of ginkgo, 10 parts of mint, 6 parts of lemon, and 14 parts of eucalyptus leaves.

[0037] The preparation method of the antibacterial plate for adjusting the indoor microenvironment, comprises the following steps:

[0038] 1) Place the formulated amount of wood powder at a temperature of 250°C for carbonization for 20 seconds, and obtain modified charcoal powder after cooling;

[0039] 2) Put the formulated amount of bamboo charcoal, coconut shell, and peanut shell into a pulverizer for crushing and mixing, then add the formulated amount of talcum powder into the mixer, and stir at a constant speed of 800r / min for 15 minutes to obtain a mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com