Hydrophobic anti-settling far-infrared wave-absorbing material and preparation method thereof

A wave-absorbing material and anti-sedimentation technology, which is applied in the direction of fireproof coatings, radiation-absorbing coatings, and special materials for cooking utensils. Anti-sedimentation and uniformity, antibacterial function of production process, good effect of far-infrared radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

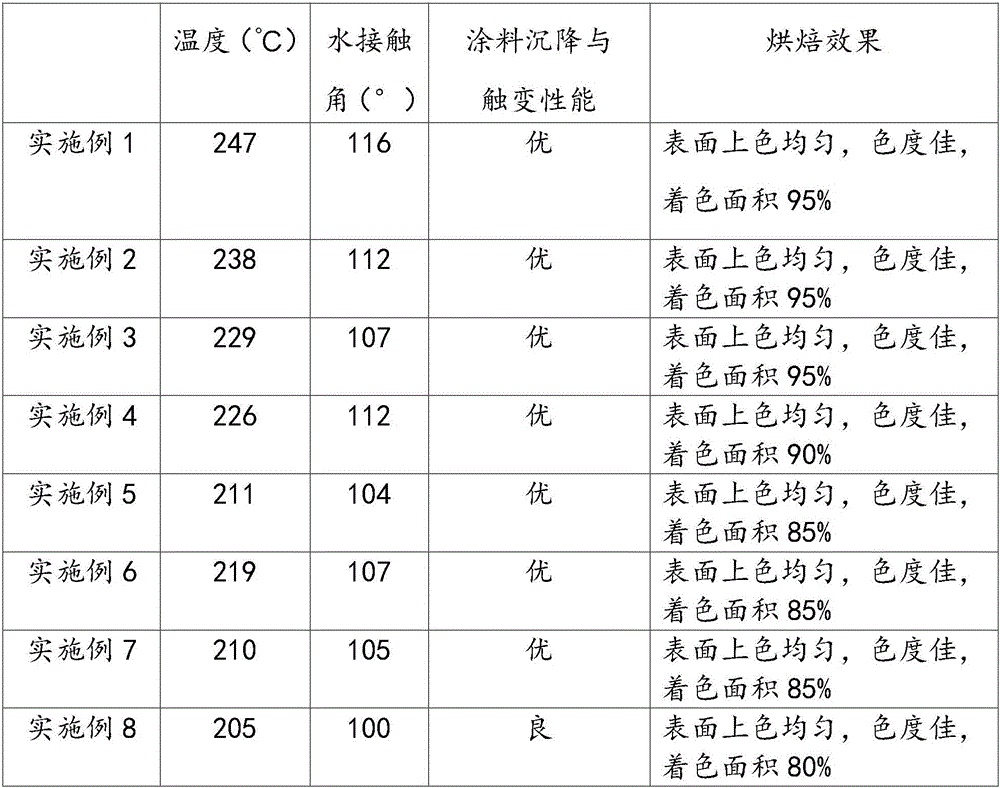

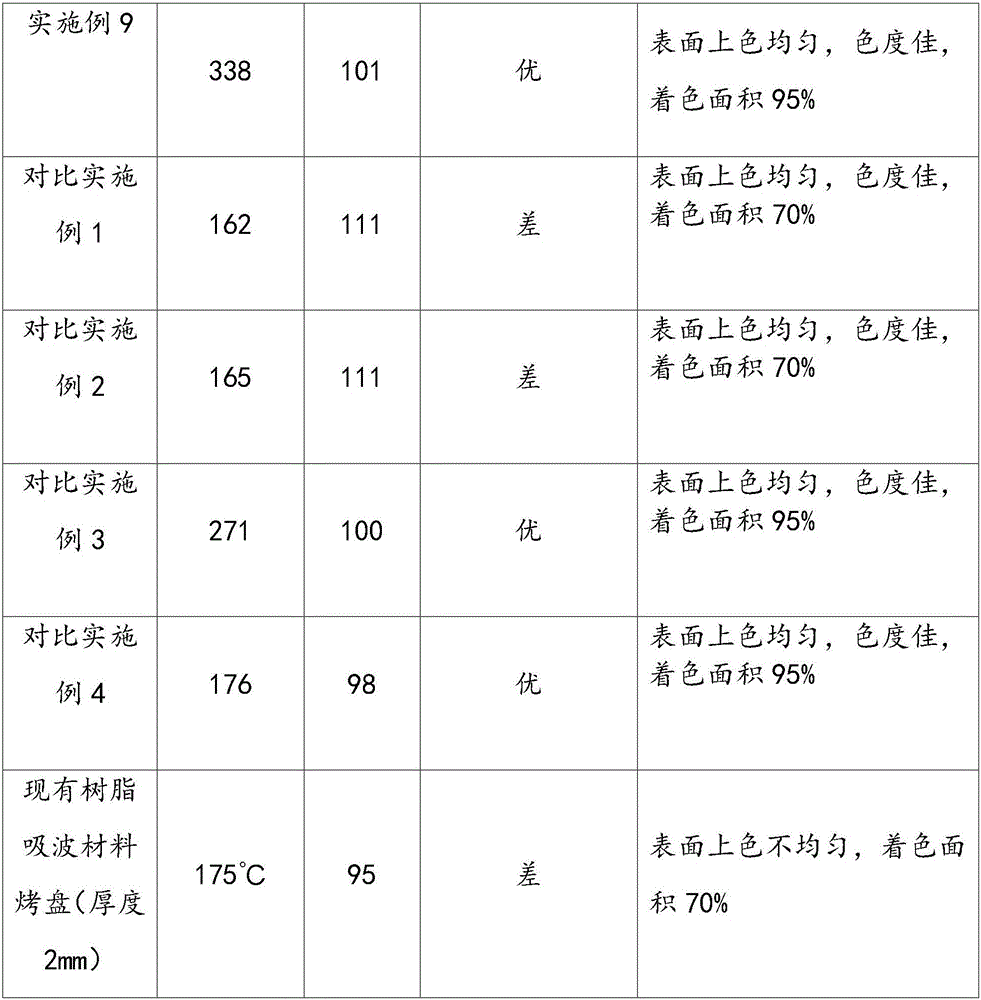

Examples

preparation example Construction

[0083] A method for preparing a hydrophobic type anti-sedimentation far-infrared wave-absorbing material, comprising the following steps: mixing each component evenly according to the above-mentioned proportion to prepare a hydrophobic type anti-settling far-infrared wave-absorbing material.

[0084] When the auxiliary agent is the mixing of dispersant, defoamer and adhesion promoter, the following preparation method can be adopted:

[0085] 1) Preparation of dispersant-binder mixed system:

[0086] Mix the binder and part of the dispersant according to the ratio, and mix them evenly to obtain a dispersant-binder mixed system;

[0087] 2) Preparation of anti-sedimentation system:

[0088] Adding anti-settling agent and antifoaming agent in proportion to the mixed system prepared in step 1), and mixing evenly to obtain an anti-settling system;

[0089] 3) Preparation of anti-sedimentation absorbing system:

[0090] adding a solvent, a wave absorbing agent and an adhesion pro...

Embodiment 1

[0109] A hydrophobic type anti-sedimentation far-infrared wave-absorbing material and a preparation method thereof. The settling agent is 10 kilograms, and the auxiliary agent is 1.2 kilograms.

[0110] The preparation method is as follows:

[0111] 1) Preparation of dispersant-binder mixed system:

[0112] Mix 64.8 kg of binder (including 25 kg of silica sol, 17 kg of aluminum sol, 10 kg of zirconium sol and 12.8 kg of silicone resin) with 0.3 kg of dispersing aid sodium lauryl sulfate, and mechanically stir at 500r / min until dispersed The agent is completely dissolved, the system is uniform, and the dispersant-binder mixed system is obtained;

[0113] 2) Preparation of anti-sedimentation system:

[0114] Add 10 kg of hydrophobic fumed silica R974 and 0.3 kg of defoamer L-1984 to the dispersant-binder mixing system prepared in step 1), mechanically stir at 100 r / min for 5 min, then mechanically stir at 600 r / min for 10 min Mix the components evenly to obtain an anti-sedim...

Embodiment 2

[0121] A hydrophobic anti-sedimentation far-infrared wave-absorbing material and its preparation method. The material is composed of: 59.1 kg of binder, 1.6 kg of wave-absorbing agent, 9 kg of solvent, and 18 kg of far-infrared powder, anti-settling The agent is 11 kilograms, and the auxiliary agent is 1.3 kilograms.

[0122] The preparation method is as follows:

[0123] 1) Preparation of dispersant-binder mixed system:

[0124] Mix 59.1 kg of binder (including 15 kg of silica sol, 15 kg of aluminum sol, 15 kg of zirconium sol and 14.1 kg of silicone resin) with 0.3 kg of dispersing aid cetyltrimethylammonium bromide, 500r / min Stir mechanically until the dispersant is completely dissolved and the system is uniform to obtain a dispersant-binder mixed system;

[0125] 2) Preparation of anti-sedimentation system:

[0126] Add 11 kg of hydrophobic fumed silica R972 and 0.3 kg of defoamer L-1984 to the dispersant-binder mixing system prepared in step 1), mechanically stir at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com