A kind of insulating coating for pantograph platform and preparation method thereof

A technology of insulating coatings and pantographs, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as inability to balance elasticity and toughness, poor impact resistance of paint films, and breakdown of vehicles, etc., to achieve Excellent insulation and impact resistance, excellent wear resistance and corrosion resistance, overall uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

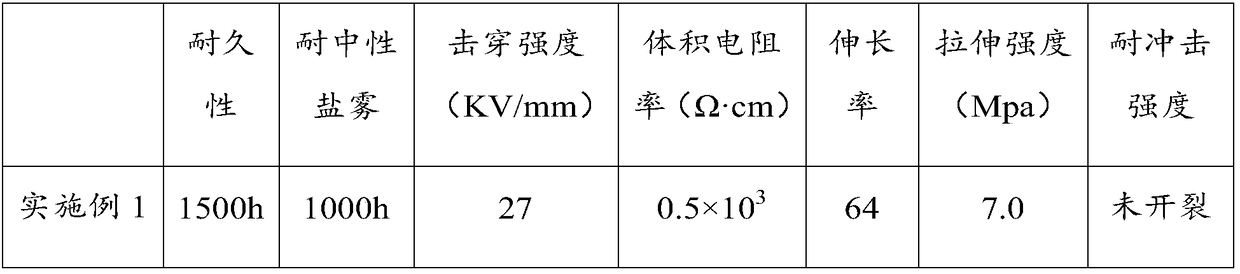

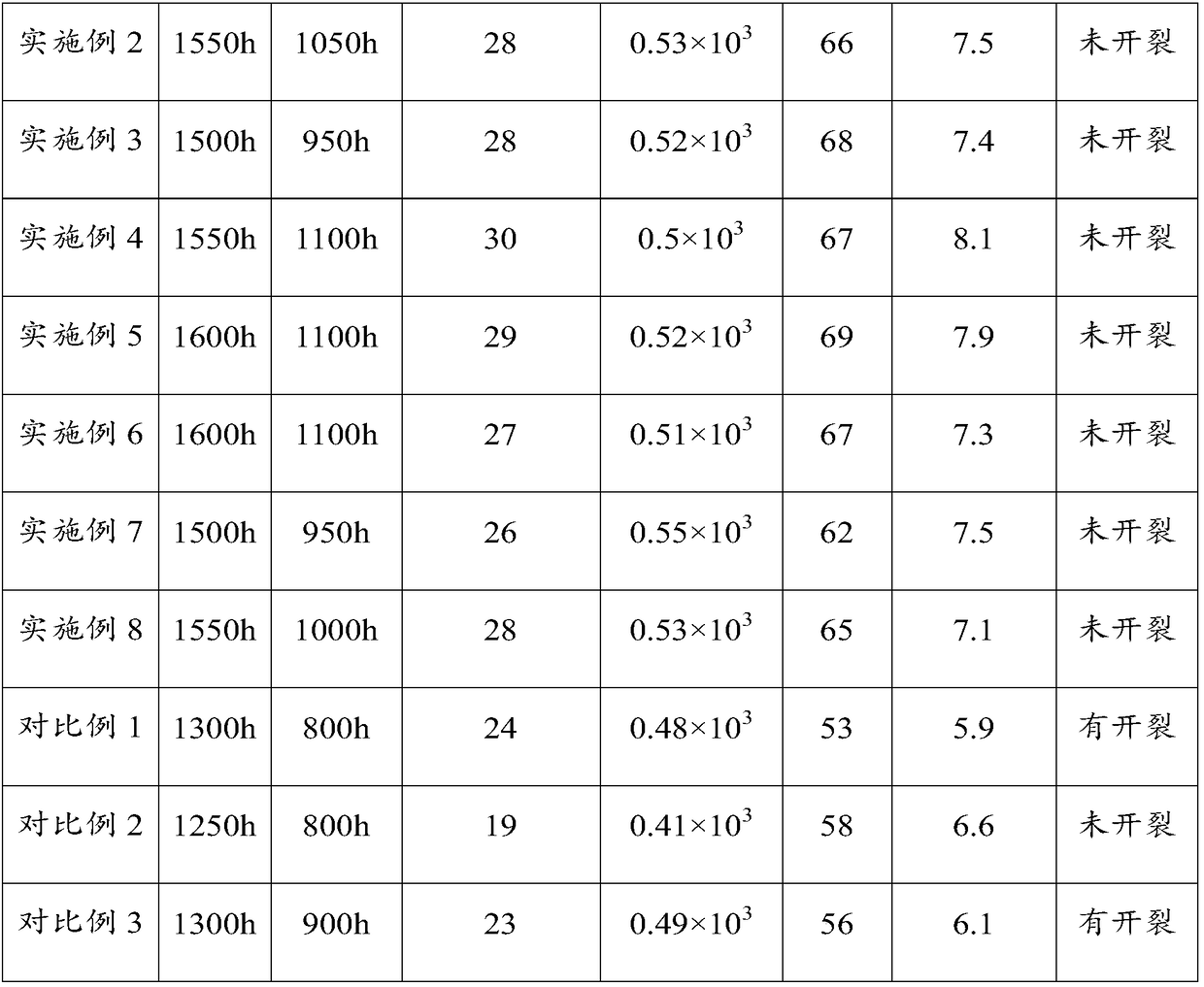

Examples

preparation example Construction

[0021] A method for preparing the above-mentioned insulating coating for a pantograph platform includes:

[0022] S1 Preparation of the first mixed component

[0023] Stir and mix the polyaspartate resin, electronic grade mica powder, talc powder, pigment, rheology aid, defoamer, dispersant, flame retardant and silicon powder to obtain the first mixed component uniformly. Specifically, add polyaspartate resin, electronic grade mica powder, talc powder, pigments, rheology additives, defoamers, dispersants, flame retardants and silicon micropowders to a high-speed mixer, and at room temperature After stirring at a speed of 800-1000r / min for 15-20min, increase the speed to 2200-2500r / min, continue to stir and disperse for 20-40min, until the fineness is ≤30μm to obtain the first mixed component.

[0024] S2 Preparation of the second mixed component

[0025] The polyisocyanate elastic curing agent and the HDI trimer curing agent are stirred and mixed uniformly to obtain the second mixed ...

Embodiment 1

[0031] This embodiment provides an insulating coating for a pantograph platform, which is prepared by the following steps:

[0032] Preparation of the first mixed component: weigh 80kg of polyaspartate resin, 40kg of electronic grade mica powder, 36kg of talc, 10kg of titanium dioxide, 8kg of silicone additives, 2kg of silicone defoamer, and polycarboxylate Add 2kg, 2kg of silicon-based flame retardant and 20kg of silicon micropowder to the high-speed mixer, stir at 800r / min for 15min at room temperature, increase the speed to 2500r / min, continue to stir and disperse for 30min, until the fineness is ≤30μm, The first mixed component is obtained.

[0033] Preparation of the second mixed component: Weigh 280 kg of polyisocyanate elastic curing agent and 120 kg of HDI trimer curing agent, add them to a high-speed mixer, and stir at 600 r / min for 15 minutes at room temperature to obtain the second mixed component.

[0034] Insulating coating preparation: adding the above-mentioned first ...

Embodiment 2

[0036] This embodiment provides an insulating coating for a pantograph platform, which is prepared by the following steps:

[0037] Preparation of the first mixed component: weigh out 90kg of polyaspartate resin, 36kg of electronic grade mica powder, 34kg of talc, 16kg of titanium dioxide, 4kg of silicone additives, 1kg of silicone defoamer, and 1kg of polyphosphate 2. Add 2kg of silicon-based flame retardant and 16kg of silicon micropowder to the high-speed mixer, stir at 800r / min for 20min at room temperature, increase the speed to 2200r / min, continue to stir and disperse for 40min, until the fineness is ≤30μm. The first mixed component.

[0038] Preparation of the second mixed component: weigh 280 kg of polyisocyanate elastic curing agent and 120 kg of HDI trimer curing agent, add them to a high-speed mixer, and stir at 800 r / min for 15 minutes at room temperature to obtain the second mixed component.

[0039] Insulating coating preparation: adding the above-mentioned first mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com