Aqueous two-component polyurethane topcoat coating and preparation method thereof

A polyurethane topcoat, water-based two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor aging resistance of coatings, achieve good water resistance, improve aging resistance, and reduce human injury. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

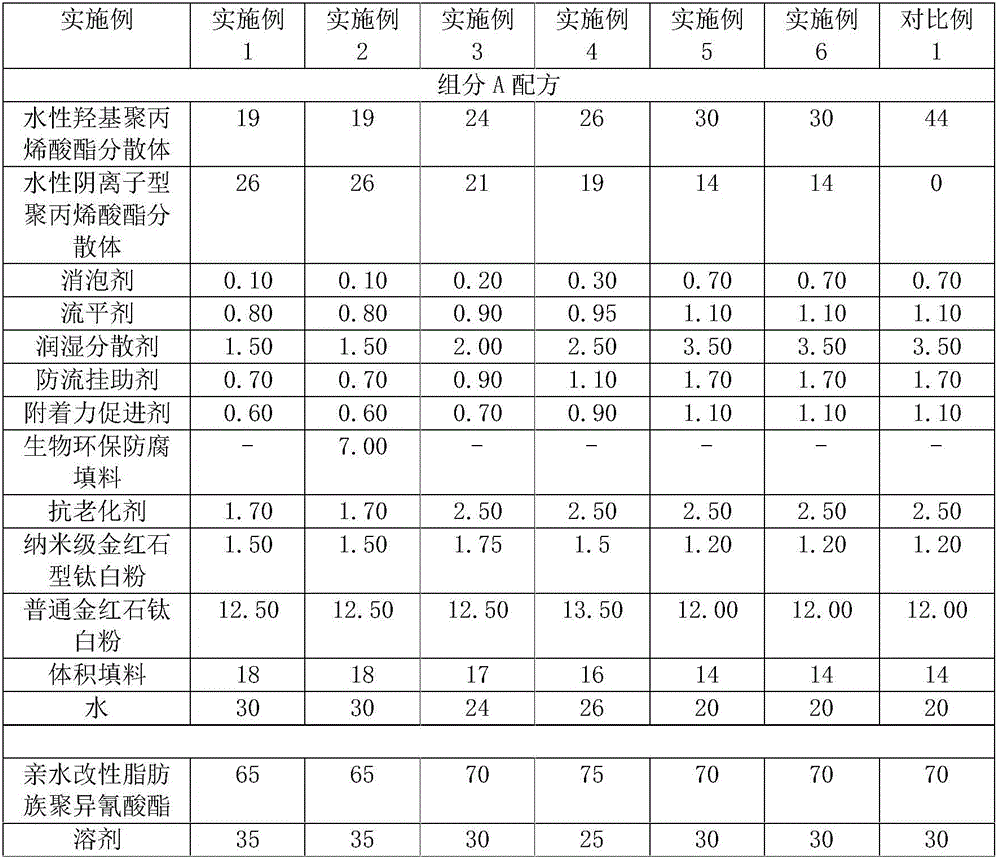

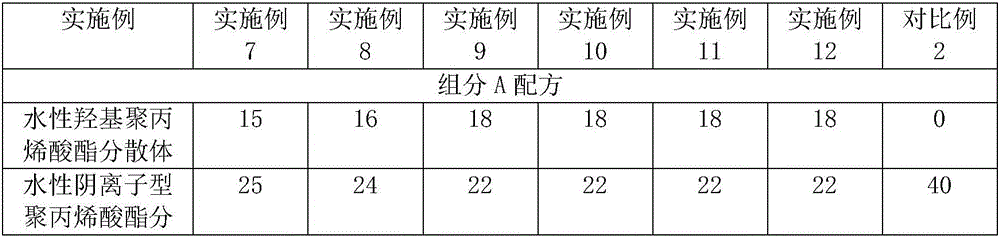

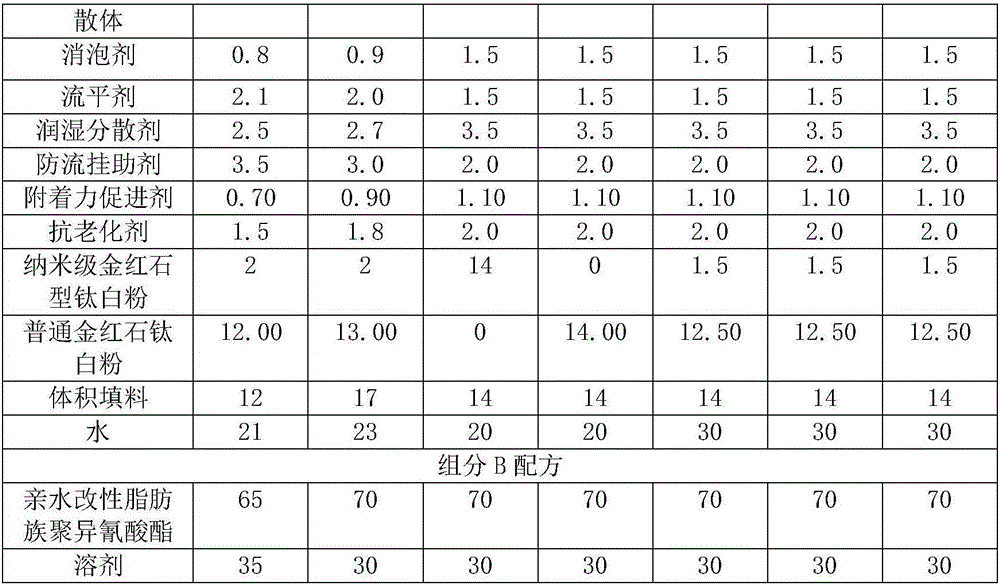

[0079] (1) The preparation method of component A: water-based hydroxyl polyacrylate dispersion, water-based anionic polyacrylate dispersion, defoamer, leveling agent, wetting and dispersing agent, anti-sag additive, adhesion promoter Blend the agent and water and stir for 10 minutes; then add titanium dioxide and volume filler and stir at high speed for 35 minutes; add the bio-environmental protection antiseptic filler together with titanium dioxide and filler.

[0080] (2) The preparation method of component B: add the solvent into the hydrophilic modified aliphatic polyisocyanate curing agent, and fully stir evenly. When the water-based polyurethane coating of the present invention is used, component A and component B are mixed in a mass ratio of 4:1 and then applied.

[0081] Performance Testing:

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com