Electro-Fenton cathode material based on lignin and preparation method thereof

A cathode material and lignin technology, which is applied in the field of lignin-based electric Fenton cathode materials and its preparation, can solve the problems of low hydrogen peroxide output and low degradation and mineralization rate of organic pollutants, and achieve low preparation cost, Effects of eliminating limitations of space-time yield and low space velocity, reducing use of toxic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

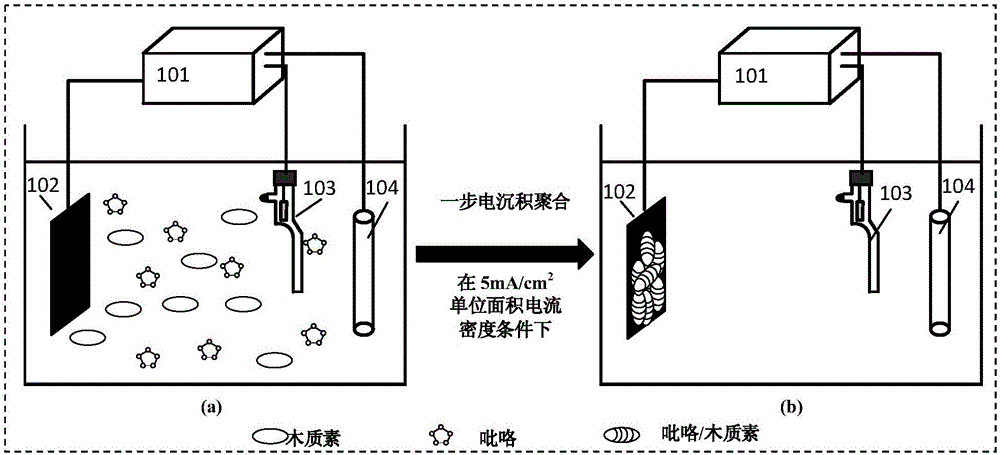

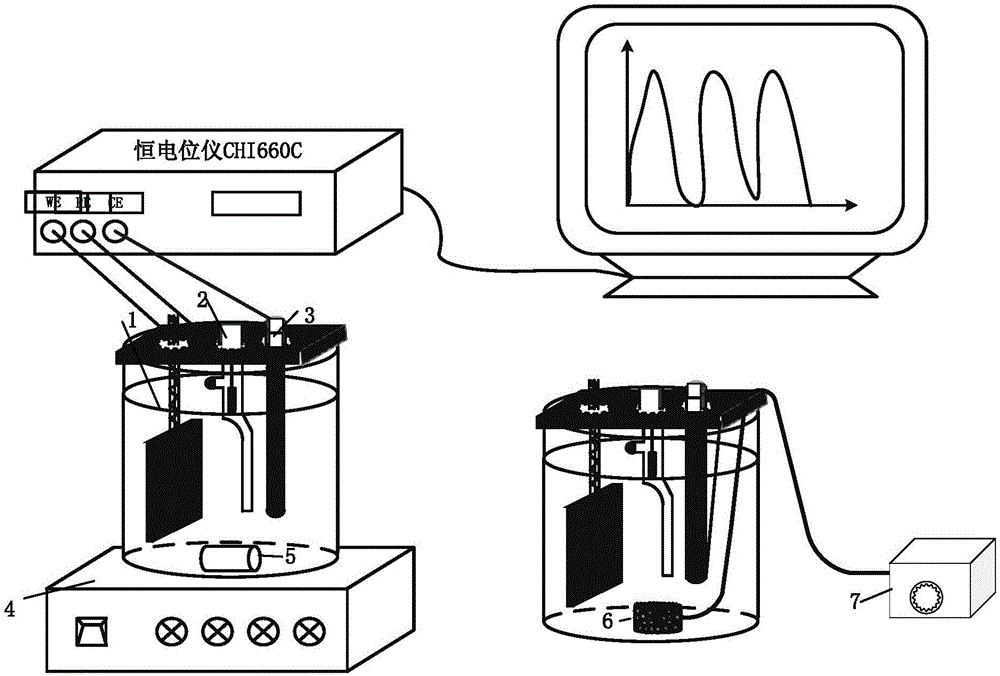

[0041] Such as figure 1 Shown is a schematic diagram of the fabrication process of the electro-Fenton system cathode. The pyrrole / lignin copolymerized cathode material (PPy / LGS-CF) was prepared as follows:

[0042] (1) Carbon-based material pretreatment: immerse the carbon-based material in 10wt% H 2 o 2, heated in a water bath at 90°C for 3 hours, and then rinsed with deionized water for 3 times; then heated with deionized water in a water bath at 90°C for 2 hours, during which the deionized water was replaced every 1 hour and the steps of rinsing were repeated; Take out the base and dry it at 60°C for 24 hours for later use;

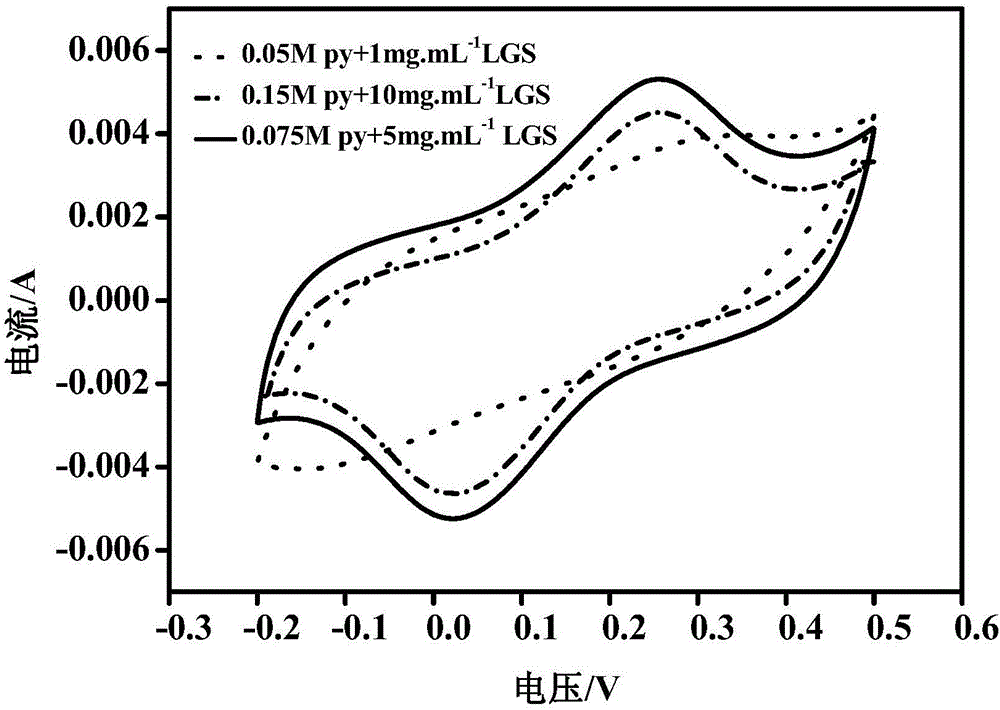

[0043] (2) Using an electrochemical workstation, a three-electrode system is used, with a pretreated carbon-based material anode as the working electrode, a platinum electrode as the counter electrode, and a saturated calomel electrode as the reference electrode. The substance monomer and lignin are dissolved in 0.1M HClO at a mass concentration ra...

Embodiment 2

[0049] The difference between this embodiment and Example 1 is that the cathode is an unmodified pretreated carbon felt substrate electrode; other conditions are the same as in Example 1.

[0050] The present embodiment finds that the unmodified carbon felt substrate electrode does not find obvious oxygen reduction peak in a certain potential range (see Figure 5 ).

Embodiment 3

[0052] The difference between this embodiment and Example 1 is that the different unit charges in the cathodic constant current electrodeposition polymerization process are within 0.5C.cm -2 , 1.0 C.cm -2 、1.5 C.cm -2 、2.0 C.cm -2 、2.5C.cm -2 , the time is 100s, 200s, 300s, 400s, 500s; the concentration of the conductive polymer monomer in the mixed solution is 0.075mol / L, and the lignin concentration is 5mg / mL; other conditions are the same as in Example 1.

[0053] The experiment found that with the increase of charge, the oxygen reduction peak becomes more obvious, and 2.0C.cm -2 PPy / LGS-CF has the best electrochemical activity (see Figure 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com