Complex enzyme hydrolysis guar gum preparation soluble diet fiber and manna oligose method

A compound enzyme hydrolysis and guar gum technology, which is applied in the field of food processing, can solve the problems of few reports on the hydrolysis of guar gum, and achieve the effect of easy separation and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

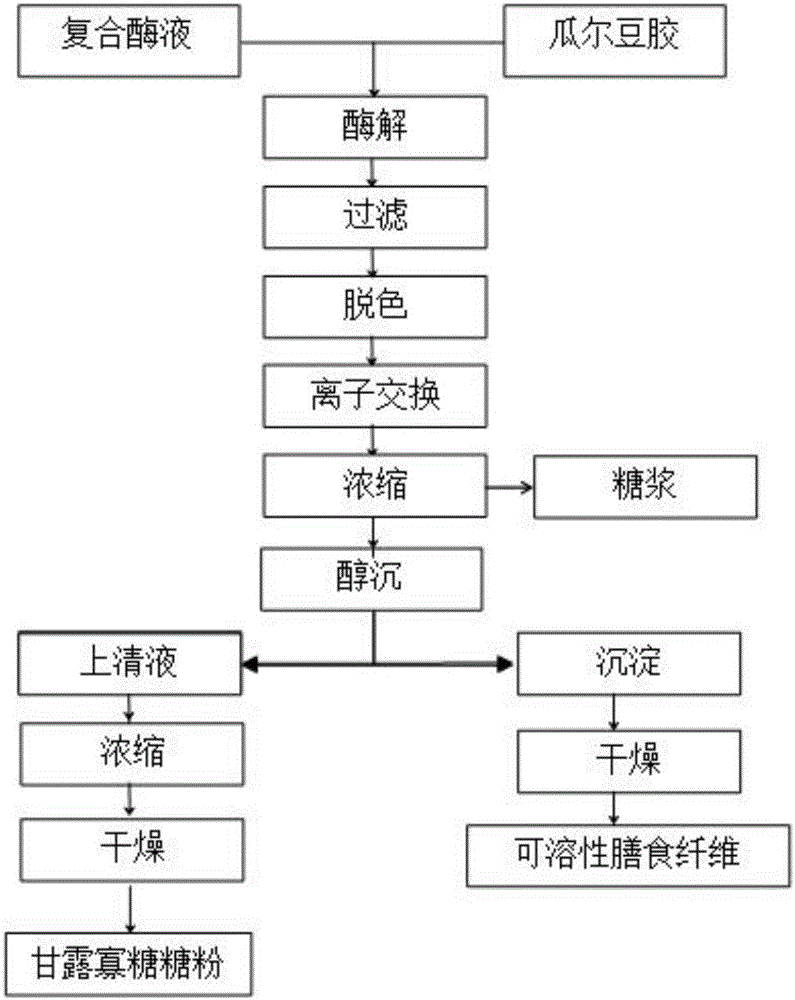

Method used

Image

Examples

Embodiment 2

[0052] Embodiment 2 Mannanase compound hydrolysis guar gum of different addition amount

[0053] Weigh 5g of guar gum and dissolve it completely in 100mL of distilled water (distilled water can also be replaced with phosphate buffer or citric acid buffer with a pH of 7.0, etc.), according to the ratio of guar gum to 100, 200, 400, 800 , 1000 and 2000 U / g were added with mannanase, placed at 50°C for hydrolysis for 8 hours, and after enzymolysis, inactivated in a boiling water bath for 10 minutes to obtain an enzymolysis solution. After the obtained enzymolysis solution was centrifuged at 10000rpm for 10min, the supernatant, that is, the crude sugar solution was collected, and its viscosity was measured with a DV-1 rotational viscometer at 25°C, and the crude sugar solution was determined by the 3,5-dinitrosalicylic acid method. The content of reducing sugar in the medium and calculate the yield of reducing sugar. The experimental results are shown in Table 1.

[0054] Table ...

Embodiment 3

[0057] Example 3 Composite Hydrolysis of Guar Gum with Different Additions of α-Galactosidase and Mannanase

[0058] Weigh 5g guar gum and dissolve it in 100mL distilled water (distilled water can also be changed to pH 7.0 phosphate buffer or citrate buffer, etc.), add mannanase according to the ratio of guar gum 1000U / g, According to the ratio of 0, 100, 200, and 400 U / g to guar gum, galactosidase was added respectively, placed at 50 ° C for 8 hours, and after enzymolysis, the boiling water bath was inactivated for 10 minutes to obtain an enzymolysis solution. After the obtained enzymolysis solution was centrifuged at 10000rpm for 10min, the supernatant, that is, the crude sugar solution was collected, and its viscosity was measured with a DV-1 rotational viscometer at 25°C, and the crude sugar solution was determined by the 3,5-dinitrosalicylic acid method. The content of reducing sugar in the medium and calculate the yield of reducing sugar.

[0059] Table 2 shows the visc...

Embodiment 4

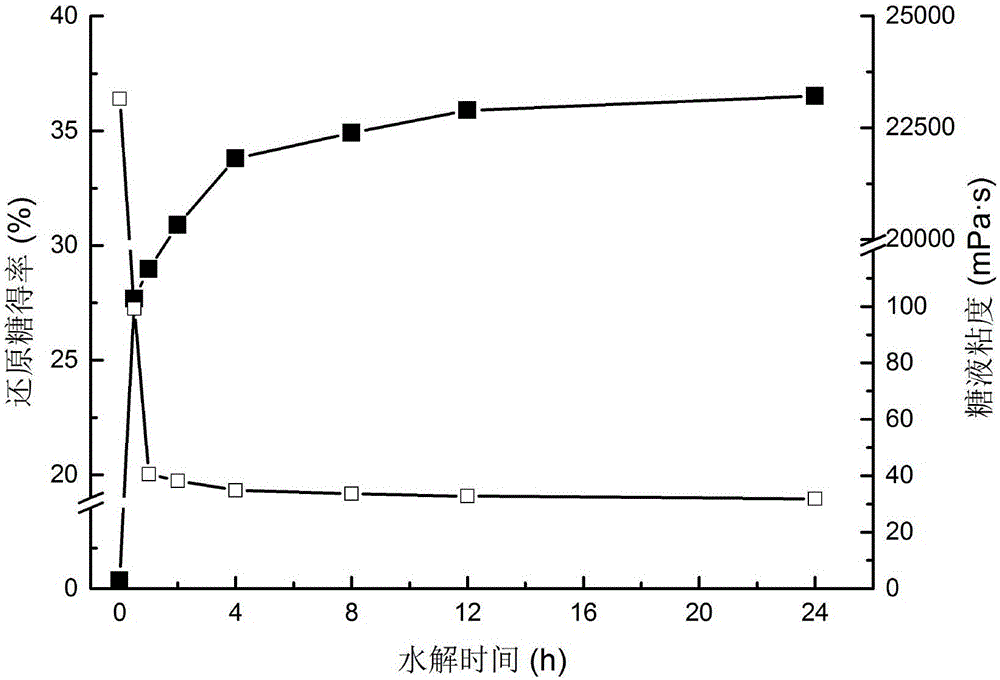

[0062] Example 4 Experimental results of different hydrolysis time compound enzyme hydrolysis guar gum

[0063] Weigh 5g guar gum and dissolve it in 100mL distilled water, add mannanase 1000U / g and galactosidase 200U / g according to the ratio of guar gum, and place them at 50°C to hydrolyze 1, 2, 4 , 8, 12, and 24 hours, after enzymolysis, inactivate in a boiling water bath for 10 minutes to obtain an enzymolysis solution, centrifuge the obtained enzymolysis solution at 10,000 rpm for 10 minutes, collect the supernatant, and obtain the crude sugar solution. The viscosity of the crude sugar solution was measured with a DV-1 rotational viscometer at 25°C, and the reducing sugar content in the crude sugar solution was determined by the 3,5-dinitrosalicylic acid method and the yield of reducing sugar was calculated.

[0064] The viscosity of crude sugar solution and the yield of reducing sugar obtained by hydrolyzing guar gum with compound enzymes at different hydrolysis times are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com