Liquid increasing granule and preparation method thereof

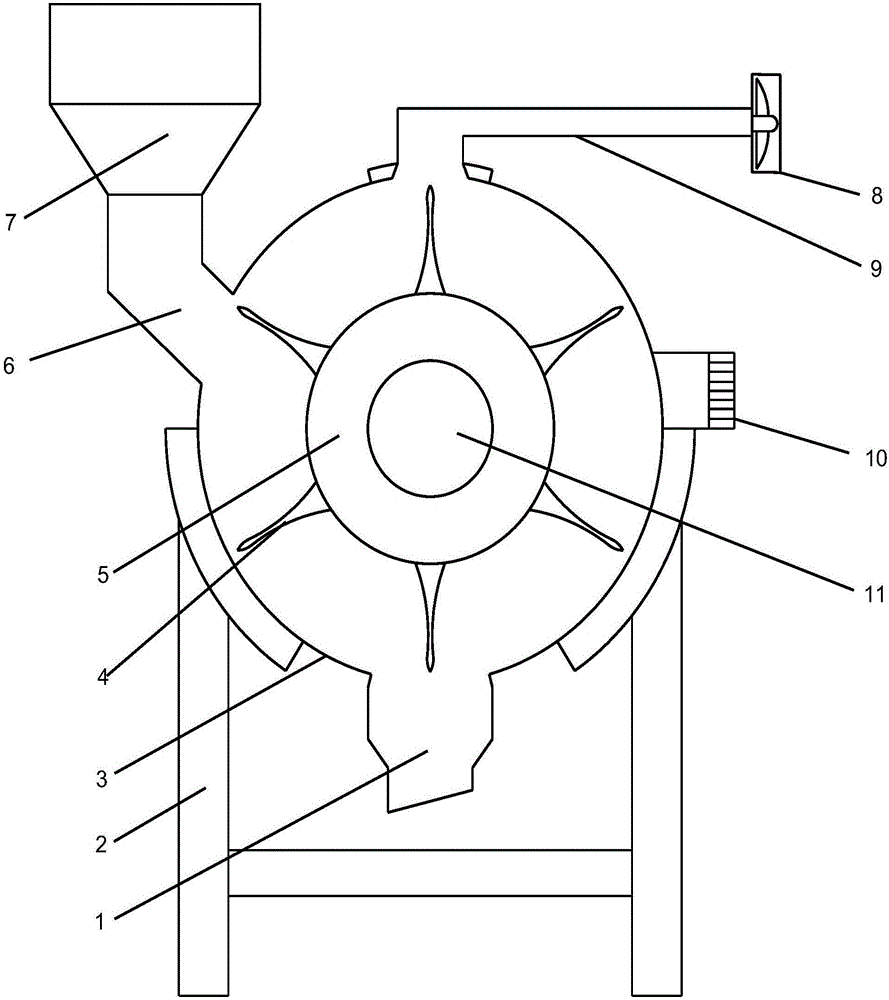

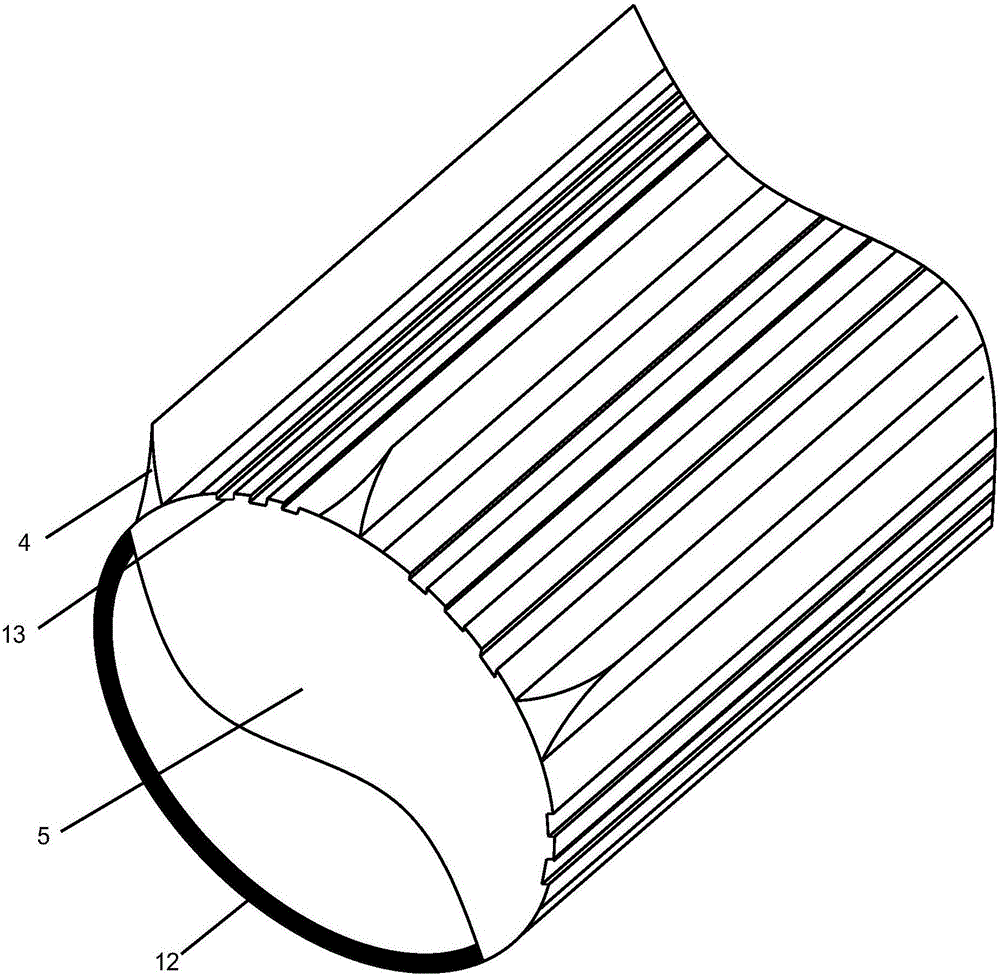

A technology of granules and concentrates, applied in pharmaceutical formulations, granular material drying, lighting and heating equipment, etc., can solve the problems of many impurities, low content of active ingredients, affecting applications, etc., achieving simple and fast operation, simple equipment structure, and high efficiency. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

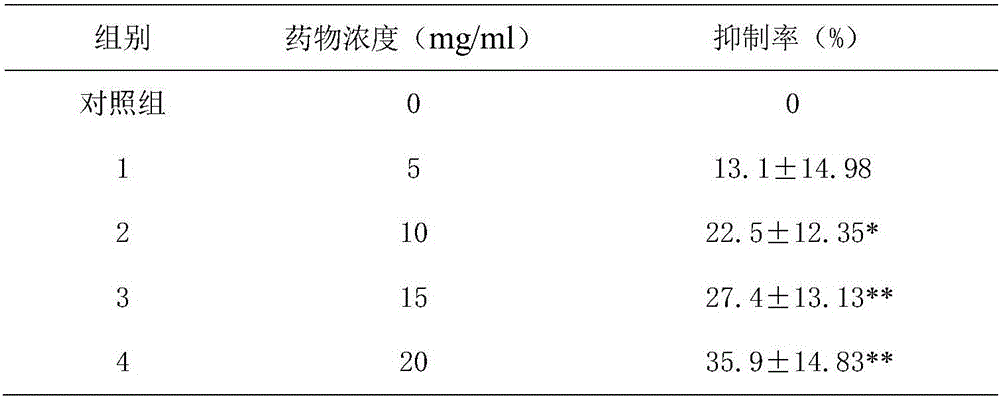

[0017] Take 270g of Radix Scrophulariae, 216g of Rehmannia glutinosa, and 216g of Radix Ophiopogon japonicus, add 10 times the weight of medicinal materials in water, soak for 0.5h, decoct for 1 hour, filter, add 8 times the weight of medicinal materials in water, decoct for 1 hour, and filter the medicinal liquid The two decoction liquids were combined, concentrated under reduced pressure to a relative density of 1.05 at 60°C, added ethanol so that the volume percentage of the alcohol content reached 75%, stirred, left to stand, filtered, and the filtrate was concentrated under reduced pressure to a relative density of 65°C 1.25, and recover ethanol to obtain concentrated solution, use silica gel to refine, pre-load the selected silica gel into the resin column, and at the same time, after diluting the concentrated solution with purified water, pass it through a reversed-phase silica gel column to remove impurities in the liquid , collect all the effluent, continue to concentr...

Embodiment 2

[0024] Take 270g of Radix Scrophulariae, 216g of Rehmannia glutinosa, and 216g of Radix Ophiopogon japonicus, add 10 times the weight of medicinal materials in water, soak for 0.5h, decoct for 1 hour, filter, add 8 times the weight of medicinal materials in water, decoct for 1 hour, and filter the medicinal liquid The two decoction liquids were combined, concentrated under reduced pressure to a relative density of 1.05 at 60°C, added ethanol so that the volume percentage of the alcohol content reached 75%, stirred, left to stand, filtered, and the filtrate was concentrated under reduced pressure to a relative density of 65°C 1.25, and recover ethanol to obtain concentrated solution, use silica gel to refine, pre-load the selected silica gel into the resin column, and at the same time, after diluting the concentrated solution with purified water, pass it through a reversed-phase silica gel column to remove impurities in the liquid , collect all the effluent, continue to concentr...

Embodiment 3

[0029] Take 270g of Radix Scrophulariae, 216g of Rehmannia glutinosa, and 216g of Radix Ophiopogon japonicus, add 10 times the weight of medicinal materials in water, soak for 0.5h, decoct for 1 hour, filter, add 8 times the weight of medicinal materials in water, decoct for 1 hour, and filter the medicinal liquid The two decoction liquids were combined, concentrated under reduced pressure to a relative density of 1.05 at 60°C, added ethanol so that the volume percentage of the alcohol content reached 75%, stirred, left to stand, filtered, and the filtrate was concentrated under reduced pressure to a relative density of 65°C 1.25, and recover ethanol to obtain concentrated solution, use silica gel to refine, pre-load the selected silica gel into the resin column, and at the same time, after diluting the concentrated solution with purified water, pass it through a reversed-phase silica gel column to remove impurities in the liquid , collect all the effluent, continue to concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com