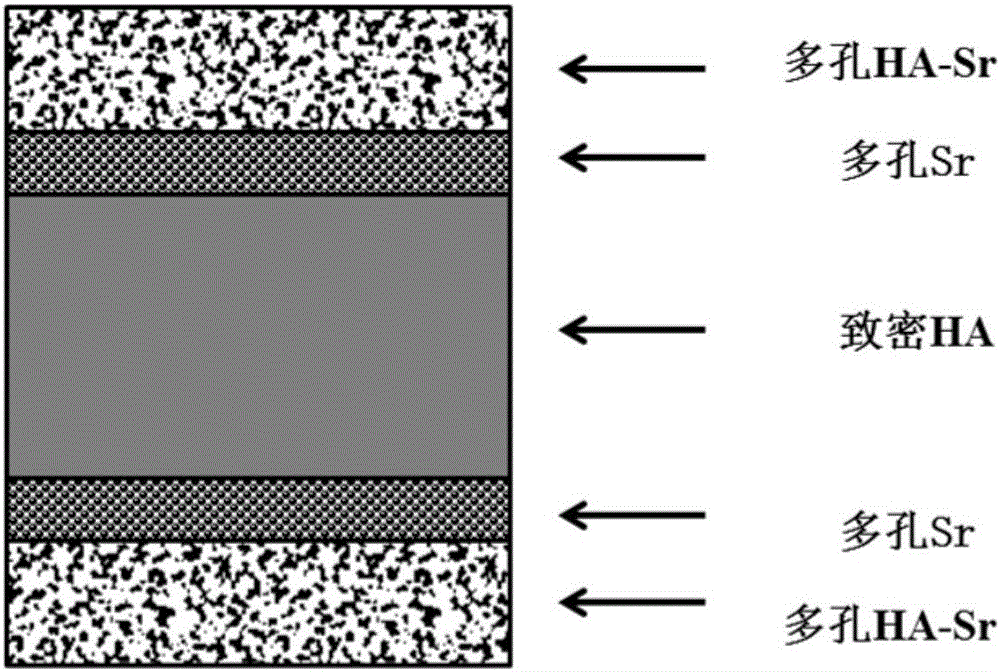

Preparation method of functionally graded porous HA-Sr bone filled support with active interlayer

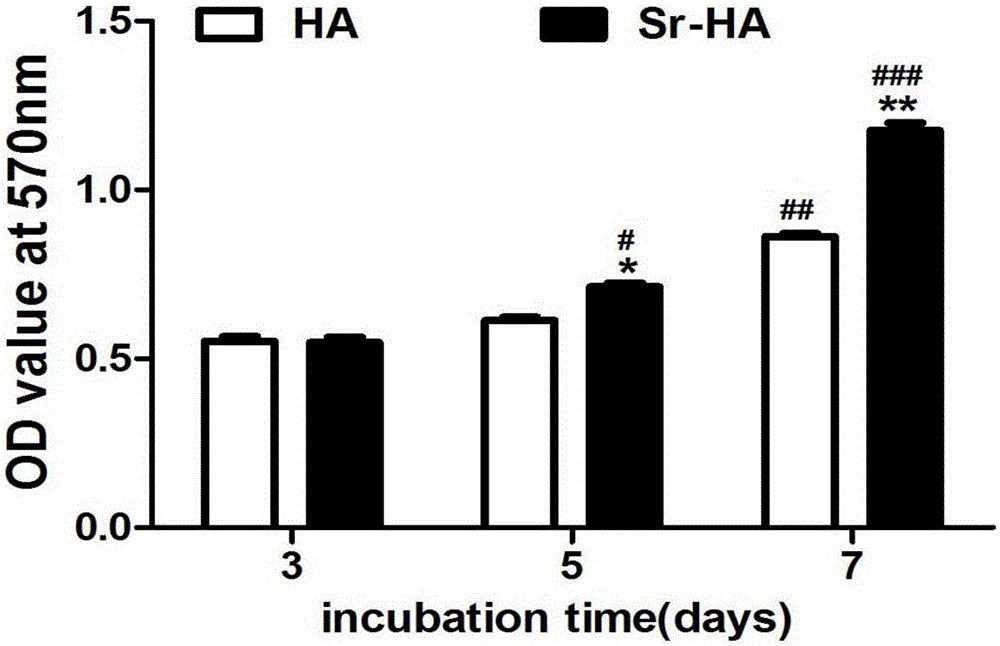

A functional gradient and interlayer technology, applied in medical science, prostheses, etc., can solve the problem that high porosity structure and high mechanical properties cannot coexist, and achieve the effect of promoting bone cell proliferation, maintaining mechanical stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

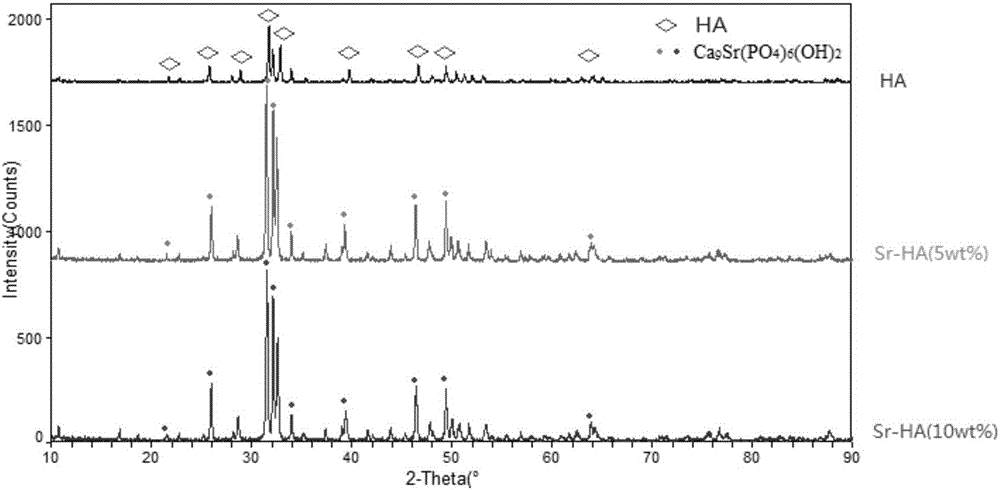

Examples

Embodiment 1

[0024] (1) According to the mass percentage of hydroxyapatite (HA) 97% and Sr 3%, respectively weigh 100 nm hydroxyapatite (HA) powder and Sr powder, put the powder into an agate ball mill jar for ball milling, After sealing with alcohol, evacuate to 20Pa, and then ball mill for 50 h, the resulting mixed HA-Sr powder is still placed in alcohol, and set aside;

[0025] (2) Mix the mixed HA-Sr powder obtained in step (1) with NH 4 HCO 3 The powder was mixed in the mixer for 120min to obtain mixed powder A; the mass percentage of HA-Sr powder in mixed powder A was 95%, NH 4 HCO 3 The mass percentage of the powder is 5%, and the average particle size of the sieve is 100 μm.

[0026] (3) According to Sr powder 95%, NH 4 HCO 3 5% mass percentage of powder, respectively weigh Sr powder and NH 4 HCO 3 The powders were mixed in a mixer for 30 minutes to obtain mixed powder B.

[0027] (4) Weigh 10 g of HA powder with a purity of more than 99.7% and a particle size of 100 nm, an...

Embodiment 2

[0032] (1) According to the mass percentage of 80% hydroxyapatite (HA) and 20% Sr, weigh 100 nm hydroxyapatite (HA) powder and Sr powder respectively, put the powder into an agate ball mill jar for ball milling, After sealing with alcohol, evacuate to 30Pa, and then ball mill for 100 h, the resulting mixed HA-Sr powder is still placed in alcohol, and set aside;

[0033] (2) Mix the mixed HA-Sr powder obtained in step (1) with NH 4 HCO 3 The powder was mixed in the mixer for 240min to obtain mixed powder A; the mass percentage of HA-Sr powder in mixed powder A was 75%, NH 4 HCO 3 The mass percentage of the powder is 25%, and the average particle size of the sieve is 700 μm.

[0034] (3) According to powder Sr 90%, NH 4 HCO 3 10% by mass of powder, weigh Sr powder and NH respectively 4 HCO 3 The powders were mixed in a mixer for 60 minutes to obtain mixed powder B.

[0035] (4) Weigh 20g of HA powder with a purity of more than 99.7% and a particle size of 100nm, record i...

Embodiment 3

[0040] (1) According to the mass percentage of hydroxyapatite (HA) 85% and Sr 15%, respectively weigh 100 nm hydroxyapatite (HA) powder and Sr powder, put the powder into an agate ball mill jar for ball milling, After sealing with alcohol, evacuate to 25Pa, and then ball mill for 80 h, the resulting mixed HA-Sr powder is still placed in alcohol, and set aside;

[0041] (2) Mix the mixed HA-Sr powder obtained in step (1) with NH 4 HCO 3 The powder was mixed in the mixer for 200min to obtain mixed powder A; the mass percentage of HA-Sr powder in mixed powder A was 80%, NH 4 HCO 3 The mass percentage of the powder is 20%, and the average particle size of the sieve is 500 μm.

[0042] (3) According to Sr powder 90%, NH 4 HCO 3 10% by mass of powder, weigh Sr powder and NH respectively 4 HCO 3 The powders were mixed in a mixer for 55 minutes to obtain mixed powder B.

[0043] (4) Weigh 15g of HA powder with a purity of more than 99.7% and a particle size of 100nm, record it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com