Filtering material for high-temperature smoke and dust and preparation method thereof

A filter material, high temperature smoke technology, applied in the direction of filtration separation, membrane filter, separation method, etc., can solve the problems of low filtration resistance, difficult processing, high temperature resistance, etc., achieve high-precision filtration, reduce energy consumption and raw material costs , reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention simultaneously provides a method for preparing a filter material for high-temperature smoke dust, which is characterized in that it comprises the following steps:

[0023] (1) Preparation of high-temperature-resistant fiber nonwoven fabric 1: Open and card high-temperature-resistant organic fibers to form a single-layer fiber web, and the single-layer fiber web is cross-laid or folded to form a multi-layer fiber with a certain thickness The net is preliminarily reinforced by a pre-acupuncture machine to obtain a high temperature resistant fiber nonwoven fabric 1;

[0024] (2) Preparation of high temperature resistant fiber woven fabric 3; high temperature resistant fiber woven fabric 3 is obtained through spinning and plain weaving process of high temperature resistant fiber;

[0025] (3) Preparation of ultra-fine glass fiber non-woven fabric 2: the ultra-fine glass fiber is directly formed into a web by melt spinning or short fiber wet-laid proces...

Embodiment 1

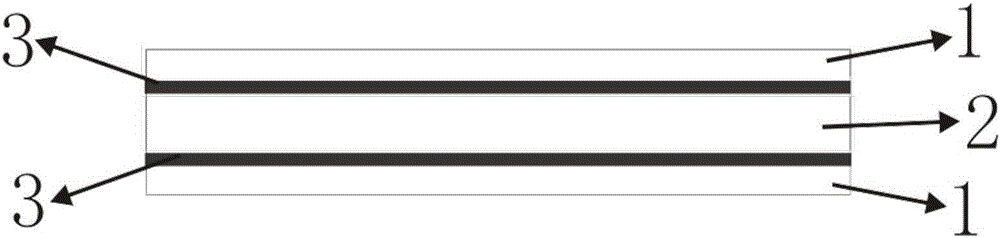

[0028] The filter material is a multi-layer symmetrical composite structure, that is, the superfine glass fiber nonwoven fabric 2 is used as the core filter layer, and the composite of high temperature resistant fiber nonwoven fabric 1 and high temperature resistant fiber woven fabric 3 is used as the upper and lower cladding layers. The high-temperature-resistant organic fiber used is polyphenylene sulfide fiber (PPS). First, it is opened and carded to form a single-layer fiber web. The single-layer fiber web is cross-laid or folded to form a multi-layer fiber web of a certain thickness. , the high temperature resistant fiber nonwoven fabric 1 was obtained by preliminary reinforcement with a pre-acupuncture machine. The high-temperature-resistant fiber is polyphenylene sulfide fiber (PPS), and the high-temperature-resistant fiber woven fabric 3 is obtained through spinning and plain weaving processes, and is combined with the high-temperature-resistant fiber non-woven fabric 1...

Embodiment 2

[0034] The filter material is a multi-layer symmetrical composite structure, that is, the superfine glass fiber nonwoven fabric 2 is used as the core filter layer, and the composite of high temperature resistant fiber nonwoven fabric 1 and high temperature resistant fiber woven fabric 3 is used as the upper and lower cladding layers. The high-temperature-resistant organic fiber used is polyimide fiber. First, it is opened and carded to form a single-layer fiber web. The single-layer fiber web is cross-laid or folded to form a multi-layer fiber web with a certain thickness. The high temperature resistant fiber nonwoven fabric 1 is obtained by preliminary reinforcement of the needle loom. The high-temperature-resistant fiber is basalt fiber, and the high-temperature-resistant fiber woven fabric 3 is obtained through spinning and plain weaving processes, and is combined with the high-temperature-resistant fiber non-woven fabric 1 through main needle punching, and the composite is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com