Method for preparing PM2.5 (particulate matter 2.5) and TVOC (total volatile organic compound) purification biological absorbent from plant waste materials

A biosorbent and plant waste technology, applied in the field of environmental protection, original ecological green biosorbent, can solve the problems of easy saturation of adsorption, corrosion of furniture, etc., and achieve good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

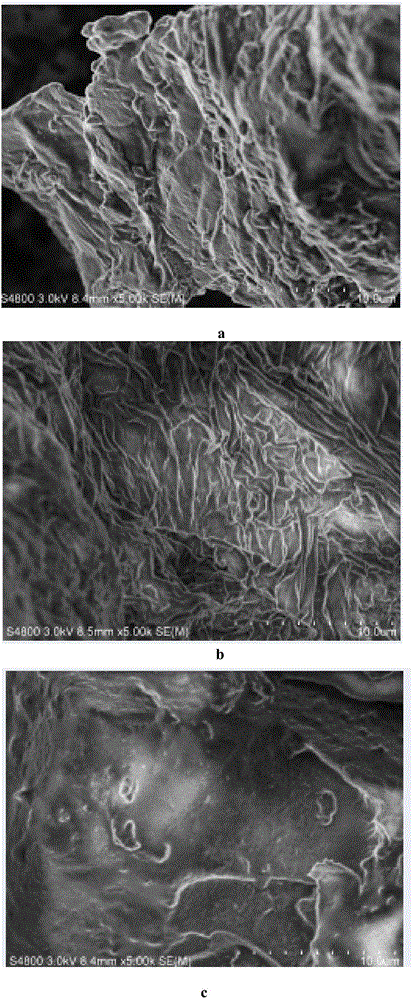

Image

Examples

Embodiment 1

[0035] The method for preparing the biosorbent for purifying PM2.5 and TVOC by using plant waste in the present embodiment, its specific steps are as follows:

[0036] (1) Processing raw materials: wash the collected peanut shells with water, then put them into boiling water and cook for 20 minutes;

[0037] (2) Rinsing and drying: Rinse the cooked peanut shells until neutral; place them in a 60°C, 6.67×102Pa drying oven for 48 hours;

[0038] (3) Alkali soaking, water bath: 1 part by weight of the dried peanut shells is put into 3 parts by weight of a NaOH solution with a concentration of 0.10mol / L and soaked for 90min, and then the soaked peanut shells are placed in Water bath in a constant temperature water bath at 60°C for 60 minutes;

[0039] (4) washing: the processed peanut shells are rinsed to neutrality with flowing distilled water;

[0040] (5) Drying: Dry the peanut shells that have been rinsed to neutrality in a drying oven at 60°C and 6.67×102Pa for 48 hours;

...

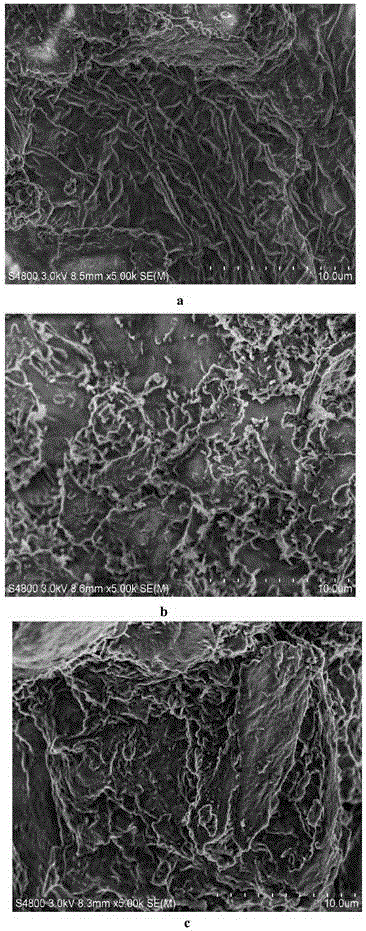

Embodiment 2

[0043] The method for preparing the biosorbent for purifying PM2.5 and TVOC by using plant waste in the present embodiment, its specific steps are as follows:

[0044] (1) Processing raw materials: clean the collected peanut shells with water, then put them into boiling water and boil for 60 minutes;

[0045] (2) Rinsing and drying: Rinse the cooked peanut shells until neutral; place them in a 100°C, 6.67×102Pa drying oven for 12 hours;

[0046] (3) Alkali soaking, water bath: 2 parts by weight of the dried peanut shells are put into 4 parts by weight of NaOH solution with a concentration of 0.30mol / L and soaked for 30min, then the soaked peanut shells are placed in Water bath in a constant temperature water bath at 100°C for 20 minutes;

[0047] (4) washing: the processed peanut shells are rinsed to neutrality with flowing distilled water;

[0048] (5) Drying: Dry the peanut shells washed to neutral in a drying oven at 100°C and 6.67×102Pa for 12 hours;

[0049] (6) Crushi...

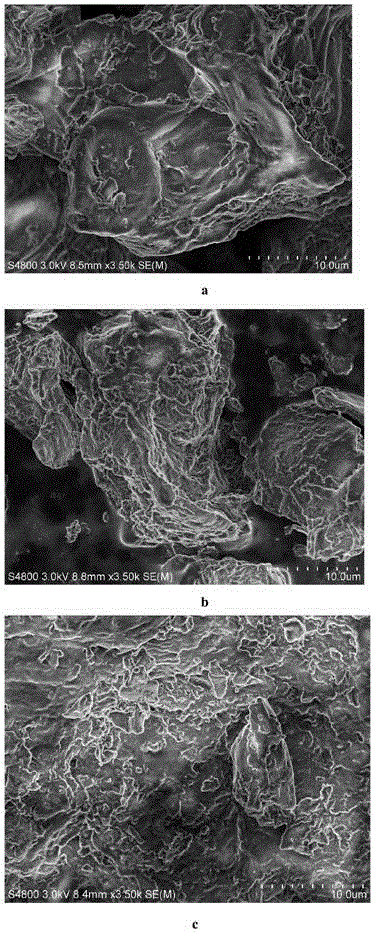

Embodiment 3

[0051] The method for preparing the biosorbent for purifying PM2.5 and TVOC by using plant waste in the present embodiment, its specific steps are as follows:

[0052] (1) Processing raw materials: wash the collected peanut shells with water, then put them into boiling water and cook for 40 minutes;

[0053] (2) Rinsing and drying: Rinse the cooked peanut shells until neutral; place them in a drying oven at 80°C and 6.67×102Pa for 30 hours;

[0054] (3) Alkali soaking, water bath: 3 parts by weight of the dried peanut shells are put into 9 parts by weight of a NaOH solution with a concentration of 0.20mol / L and soaked for 60min, and then the soaked peanut shells are placed in Water bath in a constant temperature water bath at 80°C for 30 minutes;

[0055] (4) washing: the processed peanut shells are rinsed to neutrality with flowing distilled water;

[0056] (5) Drying: Dry the peanut shells that have been rinsed to neutrality in a drying oven at 80°C and 6.67×102Pa for 30 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com