Resource utilization method of polycrystalline silicon byproduct silicon tetrachloride

A technology of silicon tetrachloride and by-products is applied in the field of resource utilization of polysilicon by-product silicon tetrachloride, which can solve the problems of large particle size of silica, excessive reaction, and difficulty in control, and achieves reduction of reaction energy consumption, Improved safety and resolution of intractable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

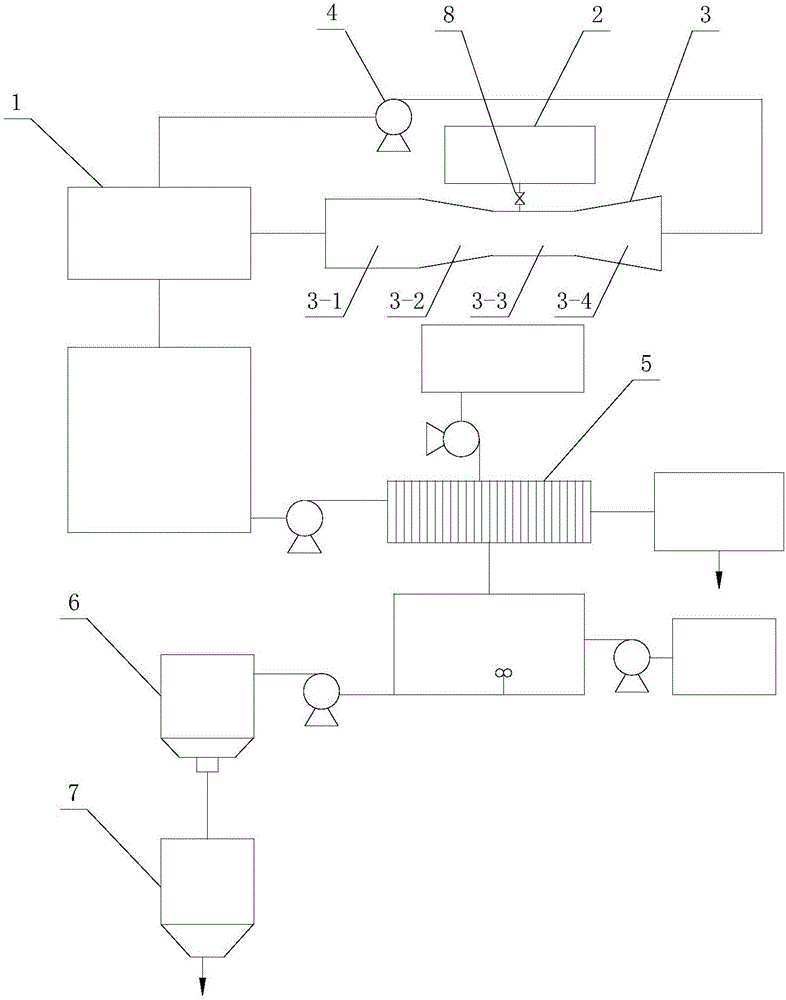

Method used

Image

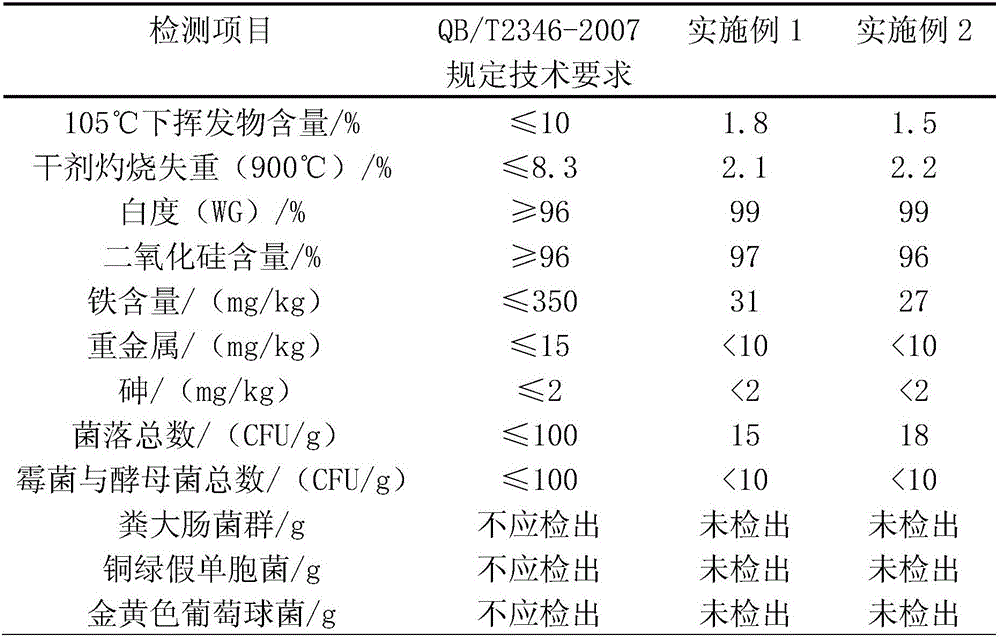

Examples

Embodiment 1

[0030] Make a mixed solution of polyethylene glycol: absolute ethanol: deionized water according to the volume ratio of 0.8:6:20, stir evenly, and set aside. The silicon tetrachloride liquid is circulated through the Venturi tube at a rate of 5L / min under the action of a mechanical pump, and enters the inlet of the cylindrical section of the Venturi tube inlet. The volume ratio of deionized water and silicon tetrachloride is 20:1 . The control valve controls the flow rate of the mixed solution to be 0.1 of the flow rate of the silicon tetrachloride liquid, adding slowly to make the silicon tetrachloride react with water. After all the mixed solution has been added, the control valve is closed, and the aging reaction is continued for 1 hour in the silicon tetrachloride storage tank. The mixture in the silicon tetrachloride storage tank is put into the storage tank and then filtered and washed by a chamber filter to obtain a filter cake. Add deionized water to the filter cake ...

Embodiment 2

[0032] Make a mixed solution of polyethylene glycol: absolute ethanol: deionized water according to the volume ratio of 0.6:5:25, stir evenly, and set aside. The silicon tetrachloride liquid is circulated through the Venturi tube at a rate of 4L / min under the action of a mechanical pump, and enters the inlet of the cylindrical section of the Venturi tube inlet. The volume ratio of deionized water to silicon tetrachloride is 25: 1. The control valve controls the flow rate of the mixed solution to be 0.12 of the flow rate of the silicon tetrachloride liquid, adding slowly to make the silicon tetrachloride react with water. After all the mixed solutions were added, the control valve was closed, and the aging reaction was continued for 1.5 hours in the silicon tetrachloride storage tank. The mixture in the silicon tetrachloride storage tank is put into the storage tank and then filtered and washed by a chamber filter to obtain a filter cake. Add deionized water to the filter cak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com