A kind of method utilizing fluorosilicate to prepare white carbon black with high specific surface area

A high specific surface area, fluorosilicate technology, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve problems affecting economic and social benefits, unsuitable for large-scale production, complex process, etc., to achieve The effect of short cycle time, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of method utilizing fluorosilicate to prepare high specific surface area white carbon black, the steps are as follows:

[0034] (1) Weigh 0.8g of ethanol into 100g of water, stir at 55°C for 5min;

[0035] (2) Add 20 g of potassium fluorosilicate to the aqueous solution prepared in step (1), and stir at 55° C. for 30 min;

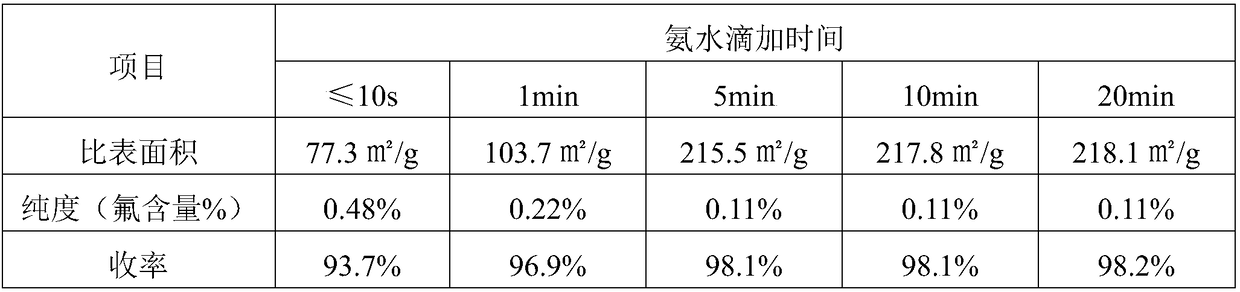

[0036] (3) Add 32 g of ammonia water dropwise while stirring up to 60° C., the dropwise addition is completed in 5 minutes, and continue to stir and react for 30 minutes after the dropwise addition is completed;

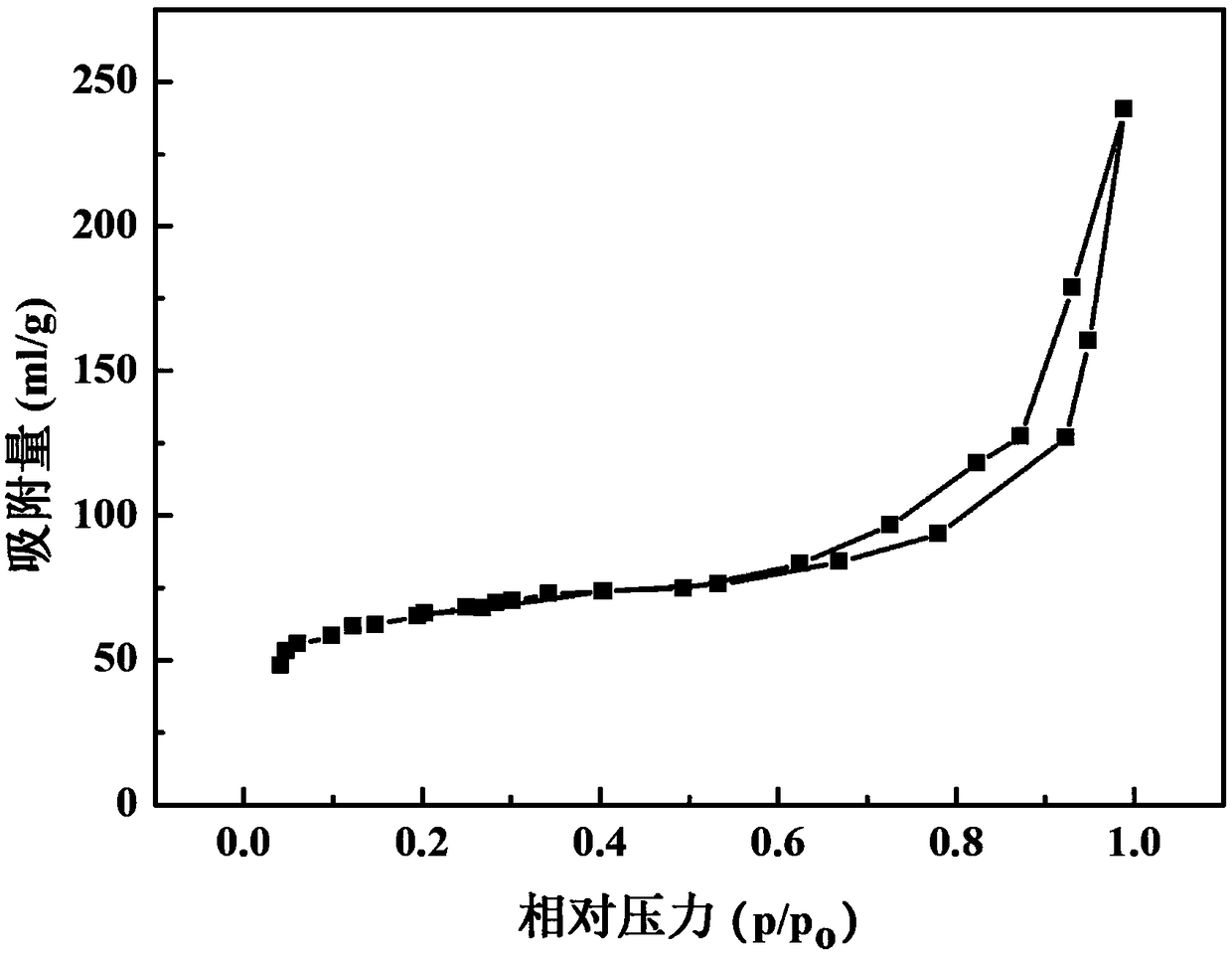

[0037] (4) Aging at 60°C for 30 minutes, filtering while hot, washing the filter cake filtrate with 55°C deionized water until neutral, and drying at 105°C to obtain 5.35g of white carbon black with a specific surface area of 215.5㎡ / g, reaching HG / T 3061-2009 Class A standard, the yield is 98.1%, and the fluorine content is 0.11%.

Embodiment 2

[0039] A kind of method utilizing fluorosilicate to prepare high specific surface area white carbon black, the steps are as follows:

[0040] (1) Weigh 0.3g of n-butanol into 100g of water, stir at 70°C for 5min;

[0041] (2) Add 25g of sodium fluorosilicate to the aqueous solution prepared in step (1), and stir at 70°C for 20min;

[0042] (3) 45g of ammonia water was added dropwise while stirring at 75°C, and the dropwise addition was completed in 10 minutes, and the stirring reaction was continued for 20 minutes after the dropwise addition was completed;

[0043](4) Aging at 70°C for 15 minutes, filtering while hot, washing the filter cake filtrate with 60°C deionized water until neutral, and drying at 105°C to obtain 7.87g of white carbon black with a specific surface area of 186.4㎡ / g, reaching HG / T 3061-2009 Class B standard, the yield is 98.5%, and the fluorine content is 0.08%.

Embodiment 3

[0045] A kind of method utilizing fluorosilicate to prepare high specific surface area white carbon black, the steps are as follows:

[0046] (1) Add 0.5kg of ethanol and 0.1kg of n-butanol to 80kg of water in turn, and stir at 60°C for 10min;

[0047] (2) Add 15kg of potassium fluorosilicate to the aqueous solution prepared in step (1), and stir at 60°C for 25min;

[0048] (3) 25kg of ammonia water was added dropwise while stirring at 60°C, and the dropwise addition was completed in 5 minutes, and the stirring reaction was continued for 30 minutes after the dropwise addition was completed;

[0049] (4) Aging at 60°C for 25 minutes, filtering while hot, washing the filter cake filtrate with 60°C deionized water until neutral, and drying at 105°C to obtain 4.01kg of white carbon black with a specific surface area of 197.3㎡ / g, reaching HG / T 3061-2009 Class A standard, the yield is 98.0%, and the fluorine content is 0.11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com