Temperable high-transparency and low-radiation coated glass and manufacturing method thereof

A low-emissivity coating and glass technology, applied in the direction of coating, etc., can solve the problems of unfavorable processing manufacturers, poor machinability of the film layer, oxidation of the metal protective layer, etc., and achieve enhanced infrared reflection, improved bonding force, light and heat The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

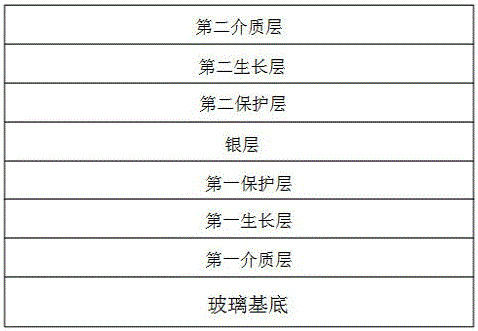

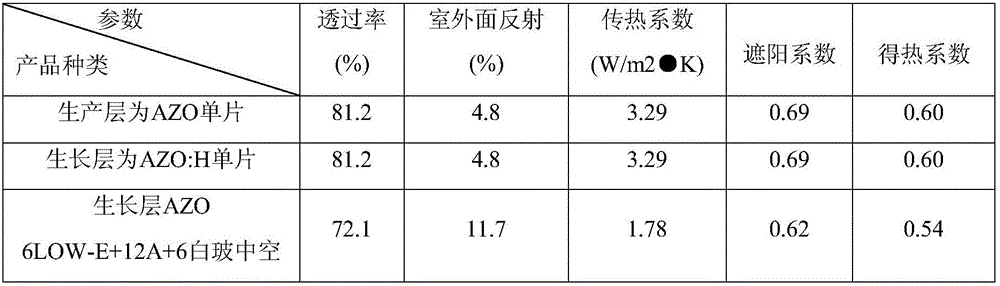

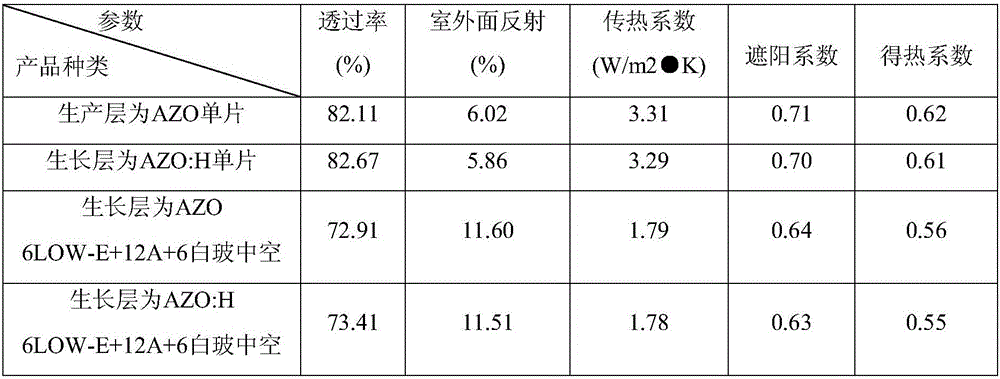

Embodiment 1

[0050] This embodiment provides a kind of coated glass, and this coated glass is single silver LOW-E coated glass, comprises glass substrate and various film layers coated on it, and film layer has 7 film layers from inside to outside, followed by The first dielectric layer Si 3 N 4 , with a thickness of 50nm, mainly to prevent Na in the float glass substrate + , Ca 2+ The role of diffusion of impurity ions into the film layer; the first growth layer is AZO:H, (H 2 Flow ratio is 6%), the doping amount of Al is 2wt%, and thickness is 35nm, provides better growth buffer layer for silver layer growth; The process is etched; the thickness of the silver layer is 12nm, which is the main functional layer of the LOW-E film; the second protective layer is NiCr, with a thickness of 2nm, which prevents the damage of the silver layer by oxygen in the subsequent processing and tempering process, and has a very good effect on the coating. Good chemical and mechanical properties The seco...

Embodiment 2

[0058] This embodiment provides a kind of coated glass, and this coated glass is single silver LOW-E coated glass, comprises glass substrate and various film layers coated on it, and film layer has 7 film layers from inside to outside, followed by The first dielectric layer Si 3 N 4 , with a thickness of 50nm, mainly to prevent Na in the float glass substrate + , Ca 2+ The role of diffusion of impurity ions into the film layer; the first growth layer is GZO:H, (H 2 Flow ratio is 6%), the doping amount of Ga is 5wt%, and thickness is 35nm, provides better growth buffer layer for silver layer growth; The process is etched; the thickness of the silver layer is 12nm, which is the main functional layer of the LOW-E film; the second protective layer is NiCr, with a thickness of 2nm, which prevents the damage of the silver layer by oxygen in the subsequent processing and tempering process, and has a very good effect on the coating. Good chemical and mechanical properties. The sec...

Embodiment 3

[0066] This embodiment provides a kind of coated glass, and this coated glass is single silver LOW-E coated glass, comprises glass substrate and various film layers coated on it, and film layer has 7 film layers from inside to outside, followed by The first dielectric layer Si 3 N 4 , with a thickness of 50nm, mainly to prevent Na in the float glass substrate + , Ca 2+ The role of diffusion of impurity ions into the film layer; the first growth layer is IZO:H, (H 2 The flow rate ratio is 6%), the doping amount of In is 10wt%, and the thickness is 35nm, which provides a better growth buffer layer for the growth of the silver layer; the first protective layer is NiCr, and the thickness is 1.5nm, which prevents the silver film from sputtering The process is etched; the thickness of the silver layer is 12nm, which is the main functional layer of the LOW-E film; the second protective layer is NiCr, with a thickness of 2nm, which prevents the damage of the silver layer by oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com