Ecological self-cleaning clog-proof water permeable brick based on construction waste and preparing method thereof

A construction waste and self-cleaning technology, which is applied to clay preparation devices, chemical instruments and methods, and manufacturing tools, can solve problems that affect the development of water cycle in nature, increase the burden of urban sewage discharge, and easily cause urban heat island effects, etc., to achieve Prevent clogging, avoid secondary pollution, and promote the effect of organic matter decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

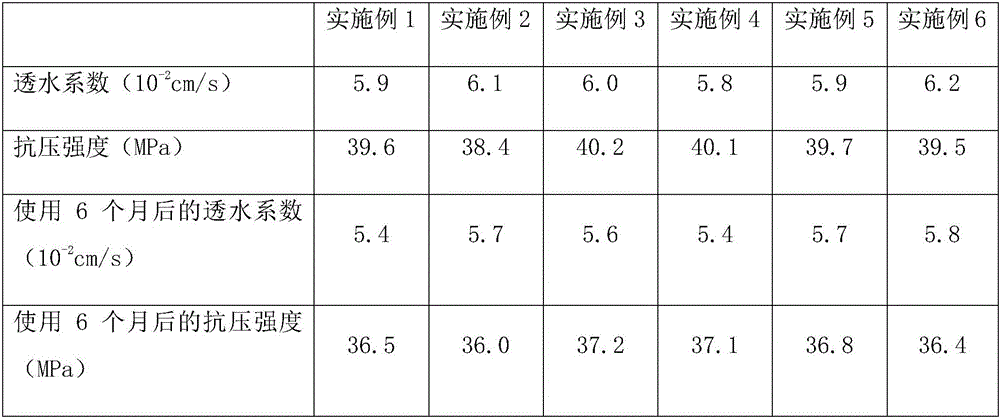

Examples

Embodiment 1

[0026] (1) In parts by weight, add 5 parts of water to 50 parts of urban sludge with a water content lower than 50%, 15 parts of brick slag with a particle size of 5 mm, and 20 parts of concrete slag with a particle size of 5 mm, and stir until the aggregate Fully wet, then add 40 parts of cement, 3 parts of water reducer and 5 parts of polypropylene fiber with a strength of 8g / D, a fineness of 5dtex, and a length of 5mm, stir well, and then add EVA emulsion with a mass ratio of 1:0.8 With 10 parts of water-based neoprene polymer and 3 parts of water, stir until the surface of the mixture is shiny, place it in a mold, and press to form a permeable base layer.

[0027] (2) In parts by weight, 5 parts of nano-titanium dioxide with a particle diameter of 20nm, an EVA emulsion with a mass ratio of 1:0.8, 5 parts of water-based neoprene polymers and 2 parts of water are fully mixed, and then the particle diameter Add 20 parts of 0.5mm slag, 5 parts of steel slag with a particle siz...

Embodiment 2

[0030] (1) In parts by weight, add 8 parts of water to 80 parts of urban sludge with a water content lower than 50%, 30 parts of brick slag with a particle size of 25 mm, and 30 parts of concrete slag with a particle size of 25 mm, and stir until the aggregate Fully wet, then add 60 parts of cement, 9 parts of water reducing agent and 15 parts of polypropylene fiber with a strength of 10g / D, a fineness of 7dtex, and a length of 20mm, stir well, and then add EVA emulsion with a mass ratio of 1:1.2 With 20 parts of water-based neoprene polymer and 7 parts of water, stir until the surface of the mixture is bright, place it in a mold, and press to form a permeable base layer.

[0031](2) In parts by weight, 9 parts of nano-titanium dioxide with a particle diameter of 100nm, an EVA emulsion with a mass ratio of 1:1.2, 10 parts of water-based neoprene polymers and 6 parts of water are fully mixed, and then the particle diameter Add 40 parts of 1.5mm slag, 15 parts of steel slag with...

Embodiment 3

[0034] (1) In parts by weight, add 6 parts of water to 60 parts of urban sludge with a water content lower than 50%, 20 parts of brick slag with a particle size of 15mm, and 25 parts of concrete slag with a particle size of 20mm, and stir until the aggregate Fully wet, then add 45 parts of cement, 4 parts of water reducer and 10 parts of polypropylene fiber with a strength of 9g / D, a fineness of 6dtex, and a length of 10mm, stir well, and then add EVA emulsion with a mass ratio of 1:1 With 15 parts of water-based neoprene polymer and 5 parts of water, stir until the surface of the mixture is bright, place it in a mold, and press to form a permeable base layer.

[0035] (2) In parts by weight, 8 parts of nano-titanium dioxide with a particle diameter of 50nm, an EVA emulsion of 1:0.9 in mass ratio, 8 parts of water-based neoprene high molecular polymer and 4 parts of water are fully mixed, and then the particle diameter Add 25 parts of 0.8mm slag, 8 parts of steel slag with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com