Preparation method of 2-mercaptobenzothiazole

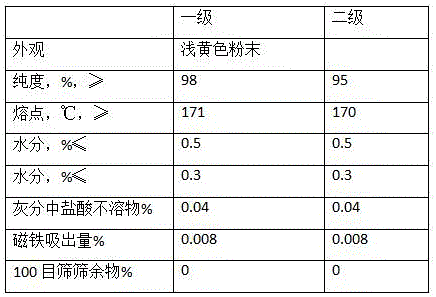

A technology of benzothiazole and benzothiazole sodium, applied in the direction of organic chemistry and the like, can solve the problems of many wastes and poor process quality, and achieve the effects of wide application, good product quality, and reduction of by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

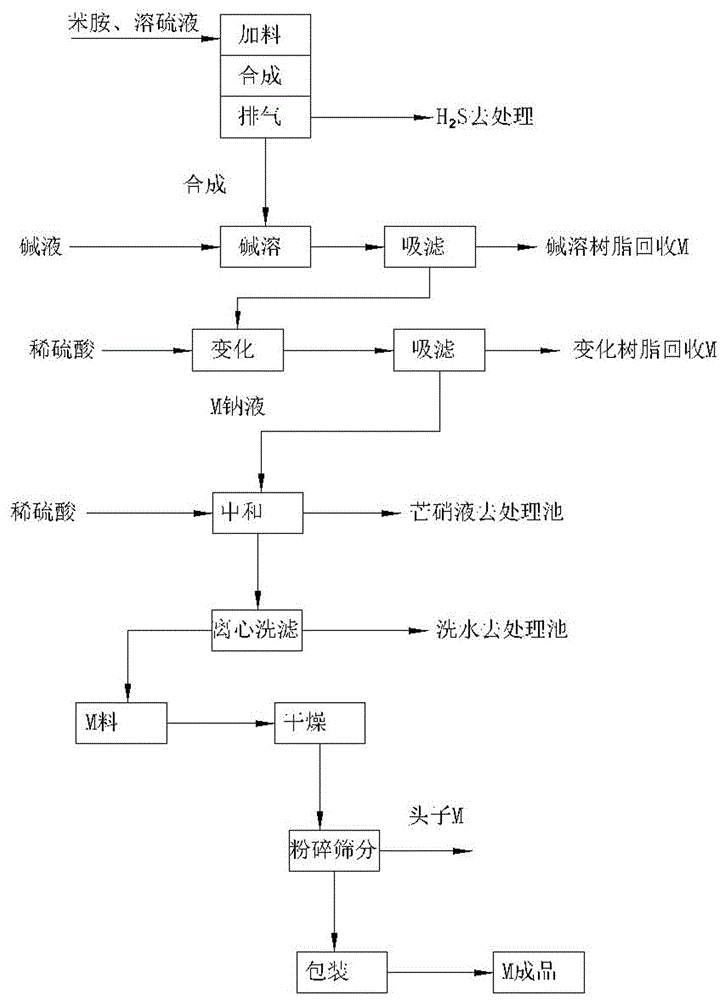

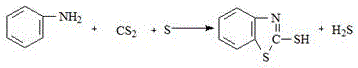

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The preparation method of 2-mercaptobenzothiazole, main equipment has aniline storage tank, aniline metering tank, sulfur dissolving tank, dissolving sulfur measuring tank, carbon disulfide storage tank, carbon disulfide metering tank, attached electromagnetic induction heater Synthetic kettle, lye tank, alkali distribution tank, lye metering tank, sulfuric acid storage tank, dilute sulfuric acid preparation tank, dilute sulfuric acid metering tank, alkali dissolution tank, changing tank, suction filter tank, washing filter tank, centrifuge, feeder, Platform scales, rotary vacuum dryers, crushing and screening machines.

[0024] Synthetic kettle with electromagnetic induction heater, including kettle body, kettle top and kettle bottom, V5000 liter cylinder, D 内 1000mm; made of boiler steel plate, with a pressure of 150atm, an 80kw electromagnetic induction heater is installed in the middle of the kettle body, and the top of the kettle is a flat head. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com